Manufacturing procurement teams operate in an increasingly unpredictable environment, where rapid shifts in demand present formidable challenges. Volatile market dynamics, driven by fluctuating consumer preferences, economic uncertainties, and global supply chain disruptions, create a complex landscape that traditional procurement methods struggle to navigate. These conditions often lead to significant operational setbacks, such as overstocked inventories that tie up capital, missed opportunities to secure cost-effective supplier contracts, or production delays that disrupt delivery schedules and erode profitability. The pressure to maintain lean operations while meeting accelerated production timelines further complicates the task, as procurement teams must balance cost, speed, and reliability under tight constraints. To remain competitive, manufacturers require agile, responsive procurement strategies capable of aligning with real-time factory floor demands.

The following section will explore how sophisticated procurement tools empower organizations to gain a competitive edge in dynamic markets. By leveraging cutting-edge technologies, these solutions enable procurement teams to respond swiftly and effectively to demand fluctuations.

How Can Procurement Stay Agile Amid Manufacturing’s Demand Fluctuations?

7Manufacturing procurement operates in a turbulent environment where demand swings—driven by market shifts, supply chain bottlenecks, and economic uncertainties—test even the most robust systems. For procurement teams, securing materials under unpredictable order volumes is a high-stakes balancing act. Missteps can inflate costs by 20-25%, disrupt production schedules, or lead to inventory surpluses, eroding profitability. This section delves into the core procurement processes and challenges in managing manufacturing’s demand volatility, highlighting the strategic procurement mindset needed to maintain agility and operational resilience.

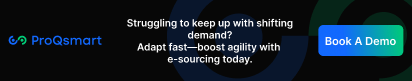

Inaccurate Demand Signals

Reliable demand forecasting is the backbone of the overall procurement process, but inaccurate signals from sales or production teams can derail planning. In manufacturing procurement today, misjudging material needs leads to overstocking, which ties up capital, or shortages that halt production lines. For example, a factory producing industrial machinery may over-order steel due to optimistic sales projections, only to face storage costs when demand dips. These errors stem from delayed or fragmented data, leaving procurement teams scrambling to adjust orders under pressure.

Supplier Lead Time Mismatches

Supplier lead times often fail to align with sudden demand spikes, forcing procurement teams to rely on expedited orders that inflate costs. In high-mix manufacturing, where diverse components are sourced, long lead times from inflexible suppliers can delay entire production runs, risking missed delivery deadlines. Effective procurement strategies require procurement teams to build strong supplier relationships that offer flexibility, but rigid contracts and limited visibility into supplier capacity hinder this process, amplifying operational risks.

Cross-Functional Data Fragmentation

Demand shifts require swift alignment across procurement processes, production, and finance teams; however, fragmented data systems create silos that hinder effective procurement decisions. For instance, procurement may source materials based on outdated production schedules, leading to excess inventory when demand drops. This misalignment results in inefficiencies, cost overruns, and strained internal relationships, as teams struggle to reconcile conflicting priorities under tight timelines. Unified data access is critical but elusive in many manufacturing environments.

How Can Procurement Overcome Demand Volatility Challenges?

Manufacturing procurement teams face relentless demand fluctuations that expose vulnerabilities like inaccurate forecasting, supplier inflexibility, and fragmented data, often inflating costs by 20-25%. To stay agile, effective procurement strategies must be adopted to enhance responsiveness and decision-making. E-sourcing offers a transformative approach by digitizing and optimizing sourcing processes, enabling teams to navigate volatility with speed and precision. This section explores how e-sourcing addresses manufacturing procurement challenges, fostering resilience and competitive advantage.

Tackling Forecasting Errors with Real-Time Insights

Inaccurate demand signals disrupt material planning, leading to stockouts or excess inventory that strains budgets. E-sourcing platforms, as part of effective procurement strategies, provide real-time market and supplier data, enabling procurement teams to refine forecasts dynamically. For example, a manufacturer producing industrial equipment can monitor supplier inventory levels and lead times, adjusting orders to match actual demand. This data-driven approach reduces forecasting errors, ensuring materials align with production needs without overcommitting resources.

Bridging Supplier Lead Time Gaps

Supplier lead time mismatches hinder responsiveness to demand spikes, forcing costly expedited orders or production delays. E-sourcing, a key component of effective procurement, streamlines supplier selection and communication, fostering partnerships with vendors capable of flexible delivery schedules. By centralizing procurement data on supplier performance, procurement teams can identify reliable partners for high-mix manufacturing, ensuring timely material availability. This agility minimizes disruptions, keeping production lines running smoothly even during unexpected demand surges.

Unifying Cross-Functional Data for Seamless Alignment

Fragmented data across procurement processes, production, and finance teams slows decision-making, exacerbating inefficiencies during demand shifts. E-sourcing integrates disparate data sources into a single platform, enabling real-time visibility and collaboration. For instance, effective procurement can access updated production schedules to avoid sourcing errors, while finance tracks spend impacts instantly. This unified approach aligns stakeholders, accelerating decisions and reducing costs from miscoordinated efforts in volatile markets.

E-Sourcing: Driving Procurement Agility in Volatile Markets

E-sourcing is a cornerstone of modern procurement, equipping manufacturers with advanced sourcing tools to navigate unpredictable demand shifts while maintaining robust supply chains. By enabling rapid recalibration of supplier networks and providing real-time visibility into procurement data and performance, e-sourcing empowers procurement teams to achieve cost efficiencies, enhance responsiveness, and ensure operational continuity in dynamic market sourcing conditions.

Real-Time Data for Swift Decision-Making

E-sourcing platforms deliver real-time supplier data and expenditure insights, enabling procurement teams to identify risks—such as delayed deliveries or quality issues—before they disrupt the overall procurement process. Dynamic dashboards and supplier scorecards provide instant access to performance metrics, allowing teams to adjust their procurement strategies within hours rather than weeks. This agility minimizes costly delays and ensures alignment with fluctuating market demands.

Automation for Rapid Response to Demand Surges

Automated e-sourcing tools streamline the overall procurement process by responding to unexpected demand spikes, reducing supplier selection timelines from weeks to days. Features like automated bidding and proposal evaluation eliminate manual errors, accelerate decision-making, and ensure timely access to critical materials, ultimately enhancing effective procurement strategies for manufacturers.

Streamlined Supplier Discovery and Onboarding

E-sourcing facilitates rapid supplier discovery and onboarding, which is critical for adapting to demand volatility in the overall procurement process. Advanced procurement technologies automate supplier vetting, data integration, and contract management, enabling procurement teams to build flexible, diverse supplier networks. This ensures manufacturers can quickly pivot to new suppliers when market conditions shift, maintaining supply chain resilience through effective procurement strategies.

Enhanced Cross-Functional Collaboration

E-sourcing platforms like ProQsmart foster seamless collaboration between procurement, operations, and other supply chain functions, enhancing the overall procurement process. Shared dashboards and real-time updates ensure all stakeholders remain aligned, reducing miscommunication and enabling faster resolution of issues, ultimately supporting effective procurement strategies and agile responses to market changes.

Proactive Risk Mitigation in Volatile Markets

E-sourcing strengthens supply chain resilience by providing comprehensive visibility into supplier capabilities and potential vulnerabilities. Integrated analytics enable procurement teams to map contingency plans, set automated alerts for disruptions, and monitor supplier performance in real time, enhancing the overall procurement process. This proactive approach minimizes risks, optimizes costs, and supports effective procurement strategies, ensuring manufacturers can adapt effectively to market volatility.

How to Implement E-Sourcing in Manufacturing Procurement?

To effectively leverage e-sourcing and address the challenges of demand volatility, manufacturers must adopt a structured implementation approach. The following steps provide a roadmap for integrating e-sourcing into effective procurement strategies, ensuring alignment with organizational goals and seamless adaptation to dynamic market sourcing conditions.

Evaluate Current Procurement Challenges

The first step involves a comprehensive assessment of existing procurement processes and inefficiencies. Teams should analyze pain points such as sourcing delays and lack of visibility into spending patterns. Mapping current workflows and gathering feedback from stakeholders—procurement, operations, and finance—helps identify bottlenecks, such as slow supplier onboarding or missed opportunities for effective procurement. This diagnostic process establishes a clear baseline, highlighting areas where e-sourcing can deliver the most significant impact.

Select E-Sourcing Tools Aligned with Organizational Needs

Choosing the right e-sourcing platform is critical to achieving effective procurement. Teams should prioritize procurement solutions that address specific requirements, such as global supplier discovery, automated bidding, or compliance tracking. Key considerations include user-friendly interfaces, robust supplier management capabilities, and integration with real-time analytics. For instance, platforms like ProQsmart offer intuitive dashboards and mobile alerts, enabling plant managers to make informed decisions on the go. Selecting technology that is both scalable and adaptable ensures long-term alignment with evolving procurement needs.

Seamlessly Integrate with Existing Systems

Effective e-sourcing implementation requires integration with enterprise resource planning (ERP), finance, and inventory management systems. This ensures data consistency, reduces errors, and provides real-time visibility into procurement activities and financial metrics. By connecting e-sourcing platforms to existing infrastructure, procurement teams can make data-driven purchasing decisions that align with manufacturing procurement strategies, minimizing disruptions and optimizing resource allocation.

Invest in Comprehensive Team Training

Successful adoption of e-sourcing hinges on equipping teams with the skills to navigate new workflows in the procurement process. Comprehensive training programs, supported by ongoing feedback and change management initiatives, help staff transition smoothly from manual to digital procurement technologies. Engaging all stakeholders—from buyers to finance teams—fosters buy-in and ensures alignment across functions, ultimately maximizing the platform’s impact on effective procurement.

Strengthen Supplier Relationships for Long-Term Resilience

E-sourcing platforms enhance supplier collaboration by providing transparent, data-driven communication channels that streamline procurement processes. Digital documentation and real-time performance tracking enable both parties to monitor contracts, assess risks, and address issues proactively. Stronger supplier partnerships, built on trust and transparency, lead to faster delivery times, competitive pricing, and mutual growth. By fostering collaborative relationships, manufacturers can maintain a flexible, resilient supply chain capable of adapting to dynamic market sourcing.

Unlock E-Sourcing’s Full Potential

E-sourcing’s advanced solutions empower teams to create precise requests for quotations (RFQs), solicit competitive bids in real time, and execute contracts with exceptional speed and accuracy. Processes that once spanned weeks are now completed in days—or even hours—through seamless, automated digital workflows.

Cutting-edge e-sourcing tools enhance efficiency by facilitating live auction events, automatically evaluating bids against predefined criteria, and maintaining robust, data-rich supplier profiles. Centralized, user-friendly dashboards provide procurement professionals with tools for real-time bid comparisons, continuous supplier performance monitoring, and proactive risk management. These capabilities ensure informed decision-making and operational resilience.

By driving significant reductions in sourcing timelines and costs, e-sourcing transforms procurement into a strategic asset. It equips organizations with the agility to swiftly align with shifting market conditions, optimize supplier relationships, and maximize value across the supply chain.

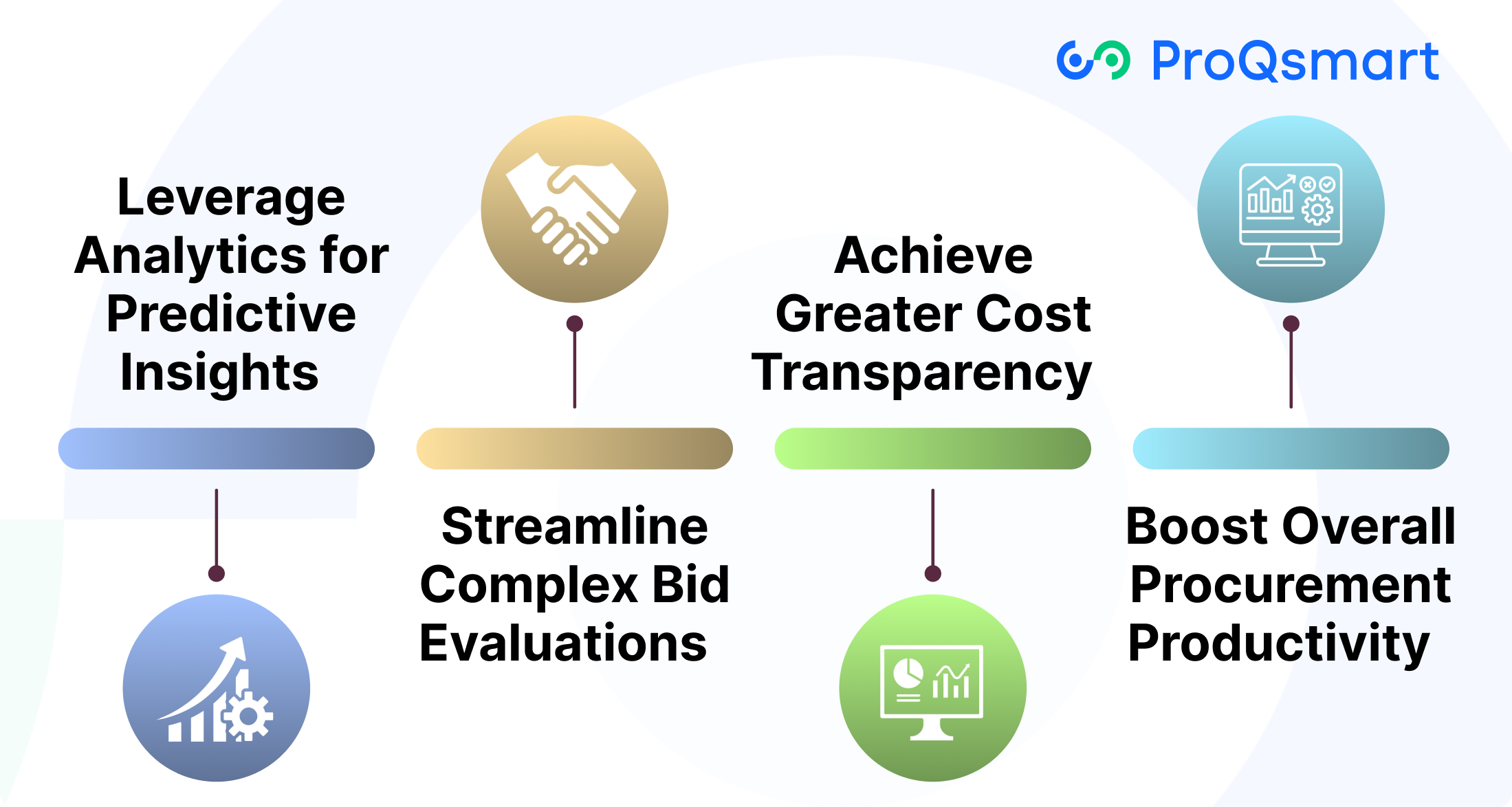

Leverage Analytics for Predictive Insights

Teams that leverage analytics within their procurement processes are able to identify trends, anticipate supply chain requirements, and proactively prepare for shifts in demand. E-sourcing platforms like ProQsmart feed in real-time data from suppliers, purchase orders, and current market rates, which supports effective procurement. This helps buyers gain a better sense of what’s on the horizon. The team can utilize past orders data to identify the optimal times to purchase more raw materials, allowing them to sidestep last-minute orders and inflated costs while eliminating waste.

Streamline Complex Bid Evaluations

E-sourcing tools enhance the procurement process by allowing teams to conduct side-by-side bid comparisons with predetermined scoring criteria, streamlining procurement processes and minimizing the time needed to review all submissions.

|

Traditional Evaluation |

E-Sourcing Approach |

|

Manual bid reviews |

Automated scoring matrices |

|

Weeks to compare |

Instant side-by-side view |

|

Prone to errors |

Higher accuracy |

Achieve Greater Cost Transparency

With e-sourcing, every step—bid to contract—is tracked, providing greater transparency into costs and enhancing the overall procurement process. This approach enables teams to identify savings opportunities, eliminate waste, and demonstrate value back to their organization’s leadership and suppliers. By fostering strong supplier relationships through effective procurement strategies, all parties remain aligned and work towards shared goals, laying the groundwork for equitable partnerships.

Boost Overall Procurement Productivity

E-sourcing significantly reduces administrative burdens by automating manual processes, enabling faster turnaround times and greater operational efficiency. Procurement teams can leverage advanced sourcing tools, reusable templates, and real-time progress tracking to streamline operations and continuously improve performance. This shift minimizes time spent on repetitive tasks, allowing teams to prioritize strategic sourcing and align procurement processes with dynamic market demands.

Conclusion: Empowering Agile Procurement for a Dynamic Future

E-sourcing delivers transformative benefits for manufacturers navigating the complexities of demand volatility. By harnessing real-time data, automated sourcing processes, and intelligent analytics, procurement teams can transition from labor-intensive, manual workflows to streamlined, responsive systems. This enables rapid adjustments to supply chains, ensuring alignment with actual market demand rather than outdated forecasts. Procurement teams can swiftly identify inefficiencies, mitigate risks, and maintain production continuity, even during turbulent market conditions.

E-sourcing aligns seamlessly with lean manufacturing procurement strategies, just-in-time delivery requirements, and sustainability goals, driving operational efficiency and cost optimization. From small-scale fabricators to large industrial operations, e-sourcing unlocks new opportunities for growth and resilience with every procurement cycle. Far from merely adapting to manufacturing demand shifts, e-sourcing empowers organizations to proactively shape their response to dynamic market sourcing conditions, ensuring a competitive edge in an unpredictable global landscape. Ready to unlock smarter sourcing? Explore ProQsmart and book a demo now!