RFP is often used to solicit competitive proposals from potential suppliers or vendors for very specific goods or services. It documents requirements, timelines and criteria for evaluating proposals to make sure the project is aligned with business goals.

In manufacturing, RFPs are vital for identifying and procuring materials, equipment, or services that align with specific quality requirements and cost considerations. Through the spirit of transparency, they contribute to the supplier selection process, encouraging competitive pricing. Specific RFPs further reduce risk by establishing detailed contractual expectations and performance goals.

When manufacturers are purchasing their raw materials or highly specialized machinery, a thoroughly conceived RFP allows them to make the best choice. It further improves their productivity and improves regulatory adherence. It’s a critical component in the drive toward operational excellence in today’s competitive manufacturing environment.

How an Effective RFP in Helps in Manufacturing Projects?

In manufacturing, RFP solutions are crucial for sourcing key strategic purchases. These RFPs can simplify the procurement process by offering a consistent structure for comparing vendor choices. Typically, the timeline spans about four weeks and includes a step process of development, administration, evaluation, and negotiation.

A well-crafted RFP should encompass essential elements such as your company’s background, project scope, budget, timeline, and criteria for proposal evaluations. For example, a manufacturer seeking specialized machinery might specify the production capacity, material requirements, and delivery deadlines, which are vital business requirements.

Providing this level of detail allows potential vendors to concentrate their proposals, facilitating an easy and objective side-by-side comparison. Moreover, RFPs encourage competitive bidding, which is essential for manufacturers aiming to cut costs while discovering the latest software solutions.

Manufacturers typically invite a number of prospective vendors. This strategy enables them to re-evaluate a larger pool of alternatives, find more opportunities for supplier consolidation, and increase sourcing efficiency.

In reality, this sometimes means extensive coordination between team leads, future vendors, and internal stakeholders to keep the process flowing gracefully. Manufacturers can gain plenty of insights from previous RFPs. By requiring examples of their previous work, they can strengthen their submissions and foster transparency.

"Don't let the complexities of RFP drafting slow you down. Download our Editable RFP Template and take the first step towards efficient vendor selection and project success."

Key Stakeholders in the RFP Process

The RFP process in the manufacturing industry exemplifies a structured procurement process that convenes a unique set of stakeholders. Each of these stakeholders plays a critical role in shaping, executing, and ensuring the success of procurement projects. By using effective RFP solutions, better collaboration and stakeholder engagement help define project needs and goals.

Role of Business Stakeholders

Business stakeholders are key in helping to set the goals of an RFP. Their technical know-how makes certain that the resulting goals are centered on operational realities and larger, strategic priorities. They inform the development of evaluation criteria — ensuring that factors like cost-efficiency, technical feasibility and long-term value inform the decision making process.

For instance, when sourcing technology, their insights ensure alignment with internal workflows and scalability. Stakeholder buy-in is vital to implementation, as it creates a sense of ownership and reduces pushback during the execution phase.

Responsibilities of Procurement Teams

Procurement teams are responsible for important tasks such as writing RFP documents, managing timelines, and keeping vendors in line with organizational requirements. They manage vendor contracts. This is especially important in today’s landscape, where vendors increasingly serve as long-term partners.

Technologies such as ProQsmart further support these efforts by automating workflows, improving compliance, and increasing transparency in supplier relationships.

Involvement of Consultants and Executives

Consultants have deep specialized knowledge that help hone RFPs, particularly in more complex projects. Executive oversight is critical to the success of any procurement transformation.

Using specialized consultants in tandem with tools like ProQsmart help teams to better resource capital expenditure sourcing with greater efficiency.

Participation of Vendors and Suppliers

Vendor engagement begins with transparency. Suppliers need to be attuned to RFP details, which may come in the form of 50 – 200+ question RFPs.

ProQsmart takes this a step further by streamlining document management and encouraging collaboration, alleviating RFP backlog headaches.

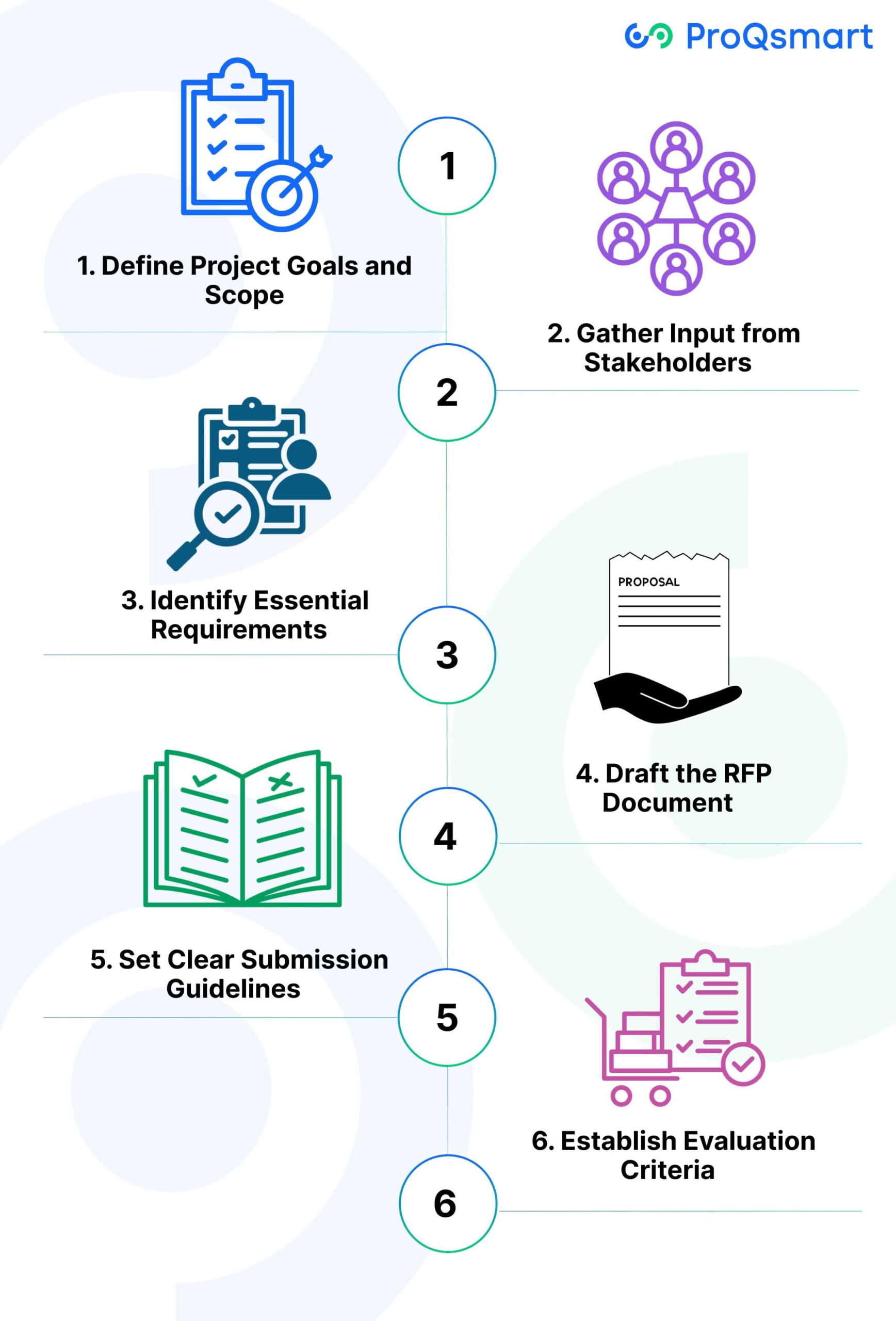

Steps to Develop an Effective RFP

An organized RFP process increases clarity, saves time, and fosters strategic alignment between your business goals and vendor capabilities. Here are the necessary steps to ensure you’re developing a strong RFP solution.

1. Define Project Goals and Scope

Having clear and concise goals is the backbone of a strong RFP. Goals help to guide the entire procurement process and ensure that the RFP stays focused on the organization’s goals.

Defining the project scope clarifies the expectations, helping vendors prepare accurate and relevant responses. For example, a manufacturing company looking to purchase automated machinery should be upfront about the equipment’s capacity and use.

That way, the responses can speak straight to their technical needs. Clear objectives and parameters further lay the groundwork for an efficient procurement approach that reduces confusion.

2. Gather Input from Stakeholders

Working and talking with all stakeholders makes for a better RFP. Early input from production managers, engineers, and finance teams greatly assist in weeding out priorities, constraints, and technical needs from the get-go.

Methods such as structured interviews or workshops can help guide these conversations. For instance, engaging with production teams can make sure specifications are in line with their operational workflows, and including finance can help keep things budgetarily aligned.

With this collaborative approach, the end result is a clear, comprehensive RFP document that is truly reflective of diverse stakeholder perspectives.

3. Identify Essential Requirements

Your RFP should outline your must-have requirements to help steer vendors. These are usually broken down into technical, functional, and compliance categories.

For example:

Technical: Equipment specifications like voltage requirements or production capacity

Functional: Delivery timelines or installation support

Compliance: Adherence to safety and quality standards

Clearer instructions on requirements help prevent confusion and ensure that any received proposals align with your needs.

4. Draft the RFP Document

Your RFP document should include sections that outline the project overview and requirements, submission guidelines, and evaluation criteria. Adopting a professional tone while using plain language goes a long way toward making a document that is easy to read and understand.

Using well-designed templates can help ensure consistency while accelerating the drafting process. Platforms such as ProQsmart further streamline the process by increasing efficiency.

They automate workflows, foster collaboration, ensure compliance, and provide critical tools like e-tenders and supplier management.

5. Set Clear Submission Guidelines

Submission guidelines should clearly outline submission deadlines, format, and content requirements. For example, mandating electronic submissions in PDF format by a specified date is a simple way to create uniformity.

Transparent rules make it easier for vendors to respond, which leads to fewer delays. Thousands of organizations use procurement platforms like Bonfire to streamline and simplify the process.

This makes it easy for vendors to submit their proposals and creates a formalized communication structure.

6. Establish Evaluation Criteria

Factors to consider include:

Technical capabilities

Cost-effectiveness

Past performance

Delivery timelines

Clear, transparent criteria helps build trust and ensure all submissions are evaluated objectively. For example, a point-based scoring system helps ensure uniform evaluations between proposals.

Essential Components of an RFP Document

The Request for Proposal (RFP) is one of the most important tools in the procurement process, especially in manufacturing. It establishes a consistent template for organizations to detail their project requirements. This approach gives vendors the freedom to be creative and submit their most competitive and customized proposal.

Together, each component of an RFP document ensures clarity, efficiency, and ultimately successful outcomes.

Component | Purpose |

Company Overview | Provides context about the organization, its values, and goals to help vendors understand the business. |

Project Goals and Objectives | Defines clear expectations and measurable outcomes for vendors to align their proposals accordingly. |

Systems and Process Requirements | Details technical and operational specifications, ensuring compatibility with vendor solutions. |

Budget and Timeline Information | Sets financial and time constraints, allowing vendors to prepare realistic and feasible proposals. |

Submission Instructions | Ensures consistency and clarity in vendor submissions by outlining precise requirements. |

Evaluation and Scoring Guidelines | Establishes a fair and structured method for assessing vendor responses. |

Company Overview and Background

Including a detailed company introduction will give potential vendors a better understanding of your organization’s background, offerings, and what makes you unique. By including detail as to operating environment, featured products, and overarching objectives, you are helping potential vendors craft more customized proposals.

Sharing your company’s mission and values up front helps create alignment and allows vendors to come to the table with solutions that best fit your org’s priorities.

Project Goals and Objectives

Detailed and clearly defined project goals are critical to successfully leading vendors and internal teams alike on the right path. For example, identifying goals such as increasing the efficiency of production or lowering the cost of procurement allows bidders to submit proposals with focused approaches.

Goals serve as benchmarks that help make comparing and evaluating proposals simple and clear.

Systems and Process Requirements

Providing clear descriptions of systems and process requirements helps prevent mismatches between vendor offerings and your organizational infrastructure. Including optional functionalities in their own separate section, such as a Price Sheet, provides added flexibility.

This process helps keep a laser focus on the most fundamental needs.

Budget and Timeline Information

An outlined budget with clear cost breakdowns and a clear timeline with dates and milestones are very important. This helps eliminate confusion and allows vendors to tailor bids to what’s realistic and expected.

ProQsmart’s budget-driven procurement feature keeps you on budget by tracking costs in real time.

Submission Instructions for Vendors

Specify format requirements (e.g., PDF or spreadsheet submissions).

Provide submission channels (e.g., email or platform upload).

Set clear deadlines and include contacts for questions.

Detailed instructions reduce errors, ensuring smooth communication.

Evaluation and Scoring Guidelines

An equitable evaluation requires clear, transparent, and published scoring rubrics. For instance, using weighted subjective criteria (e.g., 1-10 scale) across categories such as cost, quality, and regulatory compliance promotes fairness.

With auditable sourcing data, ProQsmart automates evaluations to streamline the decision-making process.

Manufacturing-Specific RFP Considerations

In the manufacturing space, developing a Request for Proposal (RFP) goes beyond simply filling out a template. It requires a nuanced grasp of highly specialized industry needs and the minutiae of process operations.

These documents make for a great start to vendor vetting. They evaluate more than price; they evaluate a vendor’s capacity to address required technology specifications, implementation of industry standards, and address the specific needs of a manufacturing ecosystem. By addressing these aspects, organizations can ensure the RFP process delivers measurable outcomes while fostering transparent and effective vendor collaboration.

Multi-Input and Output Capabilities

Manufacturing workflows tend to require the handling of many raw materials, creating many different finished goods at once. Specifying multi-input and output capabilities in an RFP is crucial to realizing the goal of more streamlined production cycles.

Vendors should be required to show their capability in designing systems that can accommodate elaborate workflows, as needed, to allow for efficiencies. For example, automated material handling systems that include software to coordinate production flows can help minimize downtime and boost efficiency.

ProQsmart’s AI-powered procurement platform automates workflows to save you time and money. Most importantly, it smoothly interfaces with multi-functional systems, powering cost savings and operational success.

Recall Reporting and Traceability Features

Manufacturers are under a tight compliance gun, especially when recalls are concerned. Adding recall reporting and traceability features into RFPs ensures that vendors are able to bring solutions loaded with features that improve safety and compliance with regulations.

Traceability systems, such as those maintaining lot numbers or serial codes, allow manufacturers to swiftly pinpoint a defective batch and pull it from stock. These features do more than just protect consumer safety; they mitigate financial and reputational risks.

Integration with Existing Systems

System compatibility is another major consideration for manufacturers who are dependent on their current ERP. Specifying integration needs within RFPs ensures vendor solutions align with daily operations without disruptions.

For instance, ease of integration with inventory management systems is crucial in ensuring operational continuity. Vendors capable of demonstrating effective integration capabilities, such as ProQsmart’s real-time collaboration and compliance tools, stand out as reliable partners for long-term success.

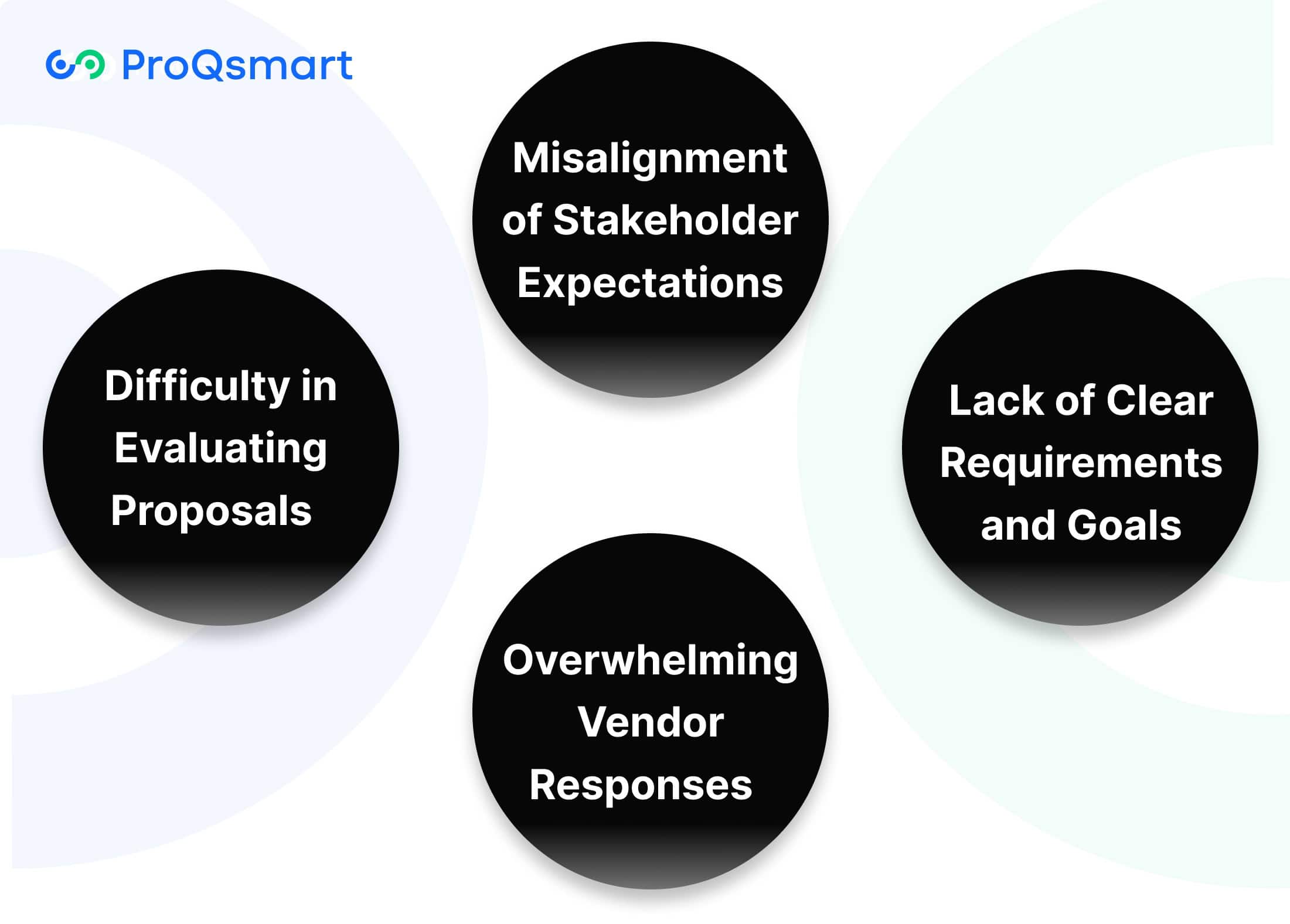

Common Challenges in the RFP Process

Navigating the Request for Proposal (RFP) process in the manufacturing sector can be complex, requiring careful orchestration and timing. Common challenges often hinder the selection of the right vendor and introduce inefficiencies, impacting the overall procurement processes. Here, we explore these typical hurdles and discuss effective RFP solutions to overcome them.

Misalignment of Stakeholder Expectations

Misalignment between stakeholders can lead to bottlenecks which not only delay timelines but make pivotal decisions more complex. With an average of nine people participating in filling out a single RFP, conflicting priorities can derail the whole endeavor.

For example, if procurement is committed to getting the lowest cost, then engineering could be committed to developing the best technical specification. Clear communication is key. Consistent meetings and communication will sync expectations, particularly keeping everyone on the same page with changing timelines.

Lack of Clear Requirements and Goals

Ambiguous requirements are another common challenge in the RFP process, frequently leading to the wrong vendors responding with proposals. If goals aren’t clearly defined, vendors can’t focus on the unique challenges at hand, wasting time and money.

Pragmatic requirements gathering is essential. For instance, setting clear material specifications or a production schedule ahead of writing the RFP allows vendors to better customize their proposals. A detailed scope prevents miscommunication and minimizes time spent on revising and resubmitting.

Overwhelming Vendor Responses

Instead, organizations routinely are inundated with proposals, with hundreds or even thousands of documents flooding into folders. This information overload can delay a decision.

Setting a realistic expectation for proposal volume and pre-screening vendors according to minimum qualifications can go a long way in making the process more efficient. Using electronic RFP platforms makes it easier to track and categorize responses, which can save even more time.

Difficulty in Evaluating Proposals

Evaluating proposals without an established set of criteria can leave reviewers open to arbitrary decision-making. Structured frameworks, like weighted scoring systems, offer a clear, transparent basis for comparison.

For example, weighting cost, quality, and delivery schedule thereby guarantees a transparent, objective decision. Using a consistent evaluation avoids the subjective bias that can occur and helps the team quickly select a vendor.

Steps for Vendor Selection and Evaluation

The vendor selection and evaluation process should be formalized and methodical. It’s key to determining which suppliers will be the best fit for your organization’s objectives. A systematic, documented process helps to promote a fair and objective, value-driven decision-making process that encourages collaboration among stakeholders.

Below is a detailed breakdown of the core steps:

Conduct initial review of proposals

Shortlist qualified vendors for assessment

Request demonstrations or presentations

Finalize vendor selection based on criteria

Conduct Initial Review of Proposals

A first pass evaluation of vendor proposals is key to filter out non-starters. This part of the process gives the evaluation committee the opportunity to evaluate proposals against pre-established standards including cost, quality, and fit with your organization.

Screening reviews guarantee only the vendors who meet the pre-established minimum requirements move forward, which saves time and effort. Leveraging platforms such as ProQsmart greatly streamlines this process by automating document collection and scoring.

Shortlist Qualified Vendors for Assessment

Shortlisting is the process of narrowing down the vendor pool after reviewing proposals. Selection criteria should include vendor experience, technical expertise and cost-effectiveness among others.

A more focused shortlist means a more streamlined evaluation process and preventing analysis paralysis. Keeping this objectivity is important, as the decisions should be based on data, not assumptions or wishes. ProQsmart’s supplier performance monitoring tools can help you gain effective insights here.

Request Demonstrations or Presentations

Live demonstrations provide a clear, real-world perspective on a vendor’s ability to deliver, filling the void between written proposals and performance on paper. For example, vendors could demonstrate their capacity to plug into your operational workflow.

This step allows you to make an informed choice by evaluating responsiveness, expertise, and alignment with your needs.

Finalize Vendor Selection Based on Criteria

Final selection should be based on explicit criteria, so that the decision-making process is data driven and transparent. Collaboration between all stakeholders, including your legal teams, is critical for successful contract completion.

ProQsmart helps make this a reality by offering tools to get ahead of compliance and work collaboratively in real-time.

Conclusion

Developing an effective RFP in manufacturing requires due diligence, a thoughtful process, and a commitment to ensuring that your intent is clearly communicated. Every piece of the process—from establishing objectives to scoring vendors—contributes to fueling victory. By creating a clear, thoughtful RFP, you pave the way for stronger relationships with vendors, more efficient workflows, and more control over costs.

Just keep in mind, the time invested in a thoughtful RFP is greatly outweighed by the seamless collaborations and impactful work that will follow. Use common sense tools and solutions to avoid problems and maintain an effective process. A well-crafted RFP isn’t merely an exercise in locating the best vendor—it’s an investment in your long-term strategic goals.

Discover how ProQsmart can transform your manufacturing procurement, enabling you to forge stronger supplier partnerships and achieve sustainable success. Book a demo today!

FAQs

What is an RFP in manufacturing?

A Request for Proposal (RFP) in manufacturing is a serious thing that outlines specific project needs and solicits vendors to respond with their proposals. For manufacturers, using effective RFP solutions helps identify the best supplier, evaluating proposals based on predetermined criteria and ensuring alignment with business requirements.

Why is an RFP important in manufacturing?

An RFP provides transparency and encourages competitive bidding among vendors, facilitating the selection of the right vendor. By using an RFP template, manufacturers can identify the highest quality suppliers, mitigate risk, and determine cost effectiveness without sacrificing quality.

Who are the key stakeholders in the RFP process?

Other important stakeholders include procurement professionals, project managers, engineers, and other decision makers who collaboratively outline requirements, score proposals, and select the top vendor for the manufacturing project.

What are the essential components of an RFP document?

A typical RFP document will outline the project scope, RFP requirements, timelines, and budget, evaluation criteria, and submission guidelines. These components promote transparency and assist potential vendors in preparing the correct proposals.

What challenges are common in the manufacturing RFP process?

Frequent issues in the procurement processes include unclear requirements, few vendor bids, and unrealistic timelines, which can hinder the RFP response. Addressing these RFP challenges from the outset leads to a more efficient process and ultimately better outcomes.

How can manufacturers evaluate RFP responses?

Manufacturers measure the value of RFP responses by scoring proposals against defined criteria, using structured RFP tools to ensure a more objective, data-driven procurement process.

How does using ProQsmart improve the RFP process?

ProQsmart takes the pain out of RFP creation by using structured RFP templates, automating vendor evaluation and comparison, and increasing internal collaboration. Its powerful yet easy-to-use platform streamlines the procurement process, increases accuracy, and ensures manufacturers find the right RFP solutions for their projects.