Supplier management is the process of developing and managing supplier relationships to improve sourcing and procurement activities while driving a more resilient business. Improve communications and performance through supplier monitoring.

With a little bit of strategy in your partnerships, you can create an agile and efficient supply chain that serves your organization’s mission and goals. Supplier management success in supplier management involves more than just supplier transactions, with emphasis on fostering long-term partnerships that lead to cost savings and reliable quality.

By leveraging data-driven insights and advanced tools, you can automate processes, mitigate risks, and ensure compliance with industry standards. Whether it is managing contracts, evaluating supplier performance, or negotiating terms, supplier management empowers businesses to focus on operational excellence.

This article explores actionable strategies and best practices to enhance your supplier management approach in manufacturing sector, ensuring your procurement processes align with organizational goals and market demands.

Supplier Management in Manufacturing

Supplier management in manufacturing is a high-stakes discipline that plays a fundamental role in shaping operational efficiency, product quality, and long-term success. Given the complexity of supply chains and their production timelines, manufacturers face distinct challenges.

Dealing with these challenges means taking a strategic approach that prioritizes cost, quality and resilience in equal measure.

Unique Challenges in Manufacturing

Manufacturers often grapple with managing a diverse supplier base, fluctuating raw material costs, and regulatory compliance. Supply chain disruptions, like delays or other shortages, can easily bring production to a standstill and result in financial losses.

For example, dealing with last-minute delays in receiving key components puts a strain on hitting production deadlines, undermining customer expectations. To avoid these risks, proactive risk management, such as scenario planning and supplier diversification, is key.

Supplier Selection and Onboarding

Choosing the right suppliers involves evaluating quality standards, reliability, and cost-effectiveness. Structured onboarding ensures seamless integration, enabling suppliers to align with production goals.

Supplier assessments, including audits and performance reviews, help ensure compatibility. ProQsmart simplifies onboarding by automating workflows, monitoring supplier performance, and ensuring compliance with regulatory standards.

Ensuring Supply Chain Resilience

Developing resilience means diversifying both suppliers and sourcing locations in order to avoid having all your eggs in one basket. This is where effective contingency planning, like holding safety stock or having multiple sources of supply, comes into play to protect continuity.

ProQsmart’s AI-powered platform increases transparency across the supply chain, allowing for data-driven decisions and thorough planning to weather or prevent disruptions.

Managing Complex Supply Chains

With more suppliers comes the need for more efficient processes and tools. Strategies such as centralized, global procurement and simplified complexity through real-time collaboration help.

Supplier management software tools can help establish transparency, efficiency, and accountability. To start, here’s how ProQsmart helps businesses through e-tenders, subcontractor management and supplier performance monitoring to achieve successful supply chain management.

Key Elements of Supplier Management in Manufacturing

To achieve successful supplier management in the manufacturing sector, companies need a comprehensive, multi-step approach. Together, this powerful approach promotes effective synergy, reduces risk, and preserves business continuity.

With procurement teams leading these efforts across the organization, they really drill down into Supplier Lifecycle Management. This involves discovering, determining suitability, and choosing suppliers that further business objectives.

Diversifying the supplier base is crucial to mitigating risks like shortages or disruptions. Strategic sourcing, guided by tools like the Kraljic matrix, categorizes suppliers based on risk and impact.

Importance of Quality Control

Quality control is vital to maintaining product standards and customer satisfaction. Regular supplier audits and assessments provide insights into adherence to quality benchmarks, ensuring goods consistently meet specifications.

Techniques such as first article inspections and ongoing batch testing help maintain consistency throughout the supply chain. Businesses that prioritize quality control reduce costly rework and delays, fostering reliability.

Contract Negotiation and Management

Negotiating clear, favorable contracts upfront is key to establishing expectations and limiting future conflicts. Clear expectations for delivery schedules, pricing agreements, and performance metrics must be set.

Technology like ProQsmart assists in continuous compliance tracking, providing real-time transparency and accuracy in contract execution.

Performance Monitoring and Evaluation

Setting key performance indicators (KPIs) for suppliers will help hold them to a measurable standard. Establishing routine review meetings along with real-time monitoring capabilities, like those offered by ProQsmart, encourages proactive problem solving.

This approach protects supplier relationships and helps to ensure continued supply.

Relationship Management and Communication

When suppliers feel heard, transparent communication fosters trust and collaboration. This creates conditions for effective joint problem-solving.

Supplier Intelligence ProQsmart improves the quality of your supplier relationships by encouraging collaboration and communicating in real-time.

Risk Management and Compliance

Protection against risks such as supply disruptions and maintaining regulatory compliance is crucial for effective supplier management processes. ProQsmart further supports through audits, centralized supplier information, and contingency planning.

How to Enhance Supplier Collaboration

Supplier collaboration is key to getting operational efficiencies and long-term growth. Creating collaborative relationships allows organizations to access innovative solutions, better manage costs, and build a more resilient supply chain.

Read on as we dig into some tangible, realistic ways to foster—and more importantly, maintain—meaningful supplier collaborations.

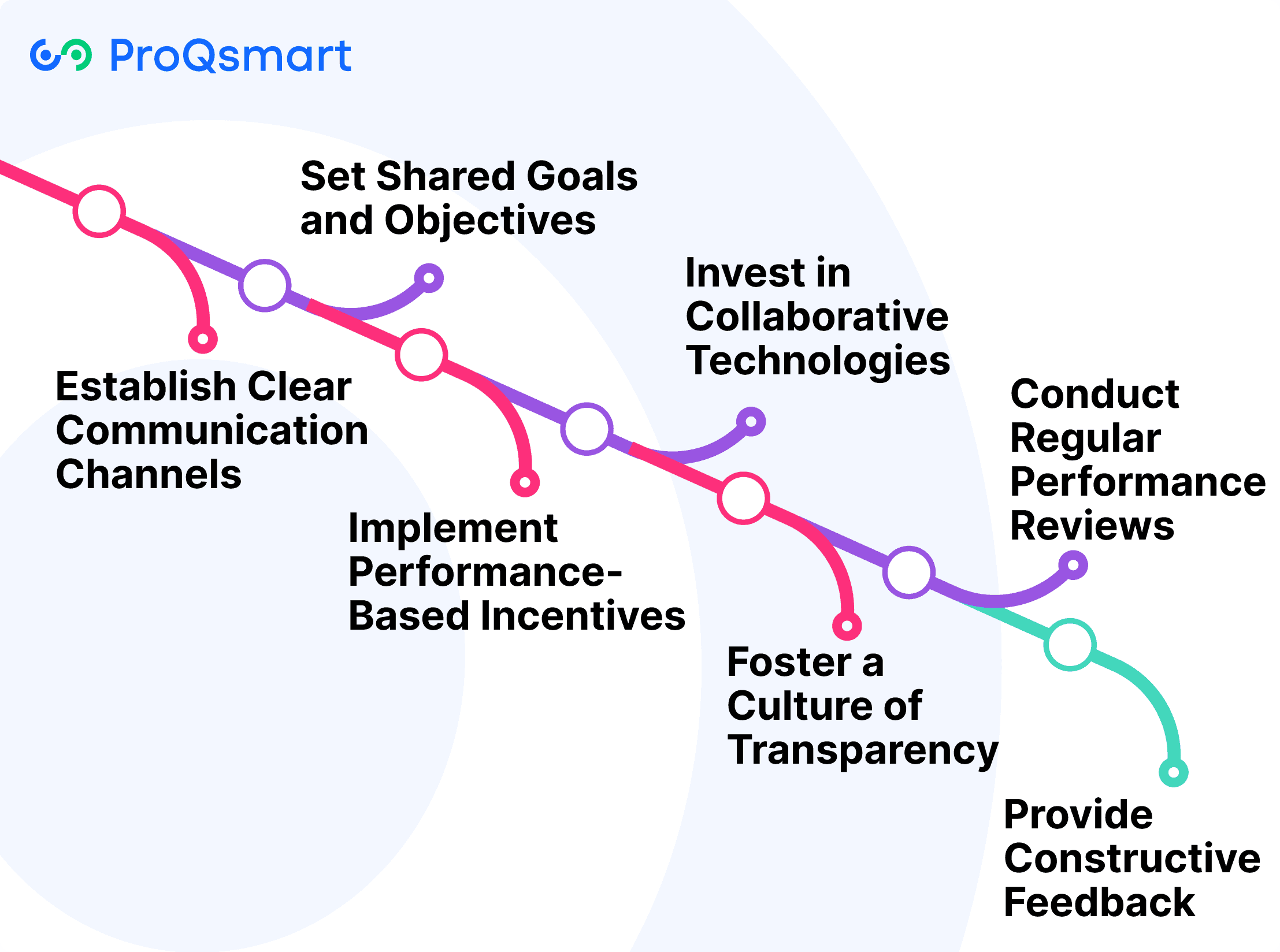

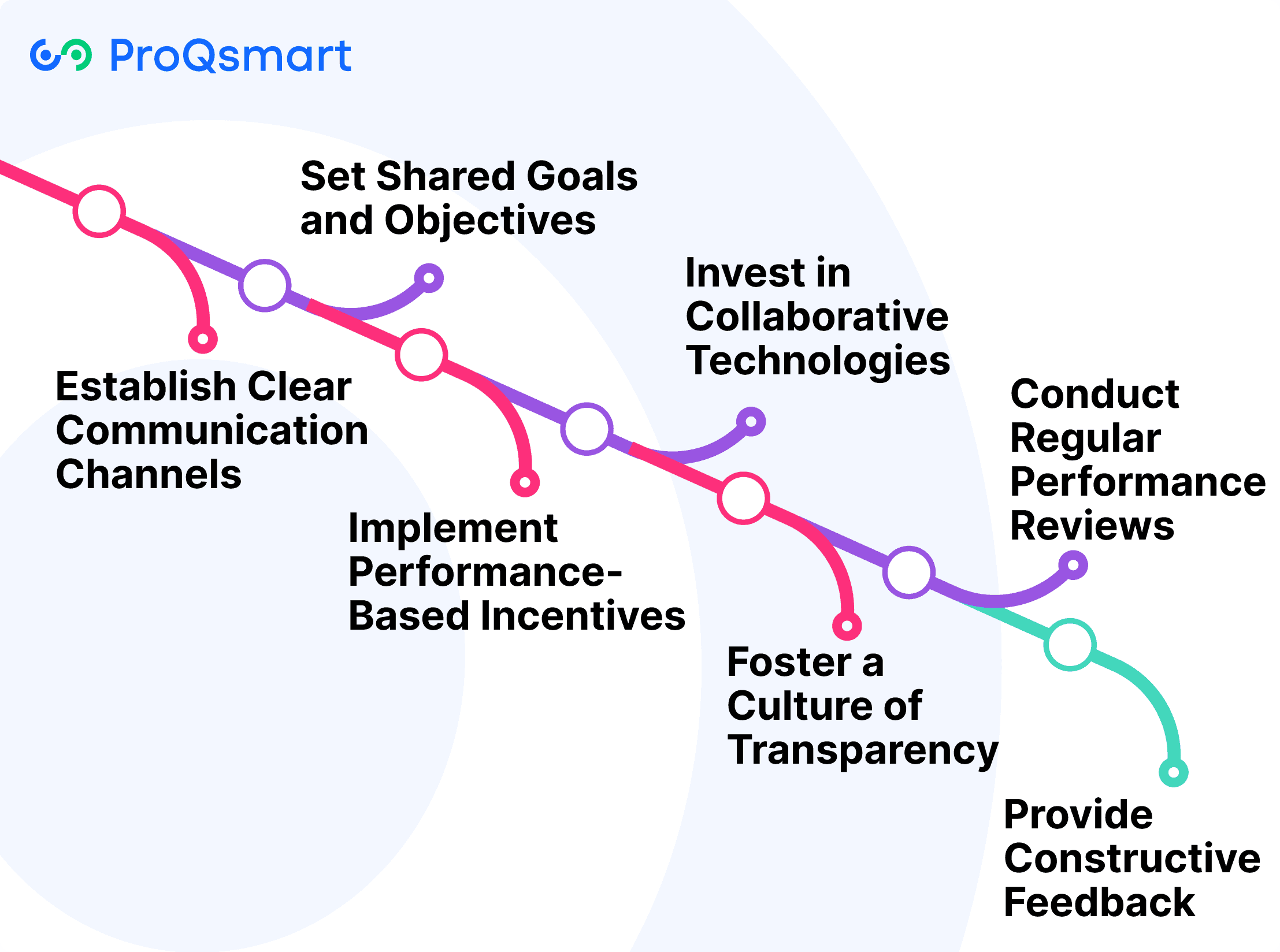

1. Establish Clear Communication Channels

Scheduled, transparent communication and feedback forms the basis of all successful collaboration with your suppliers. Clear protocols ensure information flows seamlessly, minimizing misunderstandings.

Utilizing cloud-based tools like ProQsmart allows teams to review and approve updates in real time. Routine reporting and communication provide even greater confidence and help to build trust by ensuring transparency and accountability.

2. Set Shared Goals and Objectives

From the start, effective management of supplier relationships with aligned objectives counteracts adversarial relationships and provides a path for success on both sides. By jointly detailing critical success metrics—like specific cost reduction goals or more on-time delivery—both parties can be held accountable.

3. Implement Performance-Based Incentives

Incentives are incredibly powerful tools that motivate suppliers to do more than what’s expected of them. Incentivizing achievement of specific goals—like cost-effective solutions or quality standards—helps ensure that supplier interests are aligned with organizational objectives.

Using two-way scorecards also creates an environment of transparency and mutual accountability.

4. Invest in Collaborative Technologies

Technologies such as AI-driven platforms improve the supplier experience and make managing suppliers easier. Supplier Collaboration tools like ProQsmart improves collaboration through automation of workflows, real-time sharing of data and analytics, and performance monitoring of suppliers.

Companies that utilize AI-driven supply chains notice an improvement in their forecasting accuracy of up to 20%.

5. Foster a Culture of Transparency

The third tactic—transparency—helps to establish a relationship of trust. Sharing performance data and engaging in open innovation—as with the KWs and Sponge—allows for the collective expertise to identify opportunities for joint innovation.

This approach is similar to P&G’s Connect and Develop model.

6. Conduct Regular Performance Reviews

Regularly scheduled business reviews with your strategic suppliers can help evaluate their effectiveness and improve future work plans. Grounding your decisions in measurable supplier data makes your rationale for any decision clear and actionable.

7. Provide Constructive Feedback

As with any business relationship, effective management through constructive and actionable feedback strengthens supplier performance. Quickly addressing concerns and acknowledging successes builds trust and fosters strategic supplier relationships, enhancing collaboration and commitment to continual improvement.

Supplier Management Platform: A Deep Dive

Supplier management platforms like ProQsmart streamline repeatable tasks and improve overall collaboration with your supplier base. These platforms are critical to modernizing business operations, increasing operational efficiencies and cost savings, and reducing risk throughout the supply chain.

By leveraging advanced technologies such as AI, businesses can transition from reactive to proactive supplier management, improving overall performance and ensuring compliance with industry standards.

Core Features and Functionalities

The best supplier management platforms offer robust features, such as data analytics, that provide meaningful, actionable insights into supplier performance. They further include solutions for measuring key metrics, including on-time / in-full delivery, like ProQsmart’s remarkable benchmarks of 98% and 95%.

Customization is another key functionality. Since there’s no one-size-fits-all solution, businesses would be best served by looking for a platform that adjusts to their specific needs.

Integration capabilities are vital for efficiency. From e-tenders to monitoring supplier performance, ProQsmart integrates seamlessly with current systems to enable a smooth workflow.

User-Friendly Design

For supplier platforms overall, accessibility and intuitive design are key to driving initial adoption. Platforms that are intuitive and easy to use will require less training and allow everyone from every stakeholder group to interact with the platform seamlessly.

ProQsmart’s built-in, real-time collaboration tools, for instance, help teams work together more easily, improving decision making and overall efficiency.

Choosing the Right Platform

Choosing the right supplier management platform requires careful consideration of features, vendor support, and user reviews. ProQsmart stands out with its AI-driven tools, delivering unmatched transparency and automation, which enhances supplier management processes while aligning procurement with organizational goals.

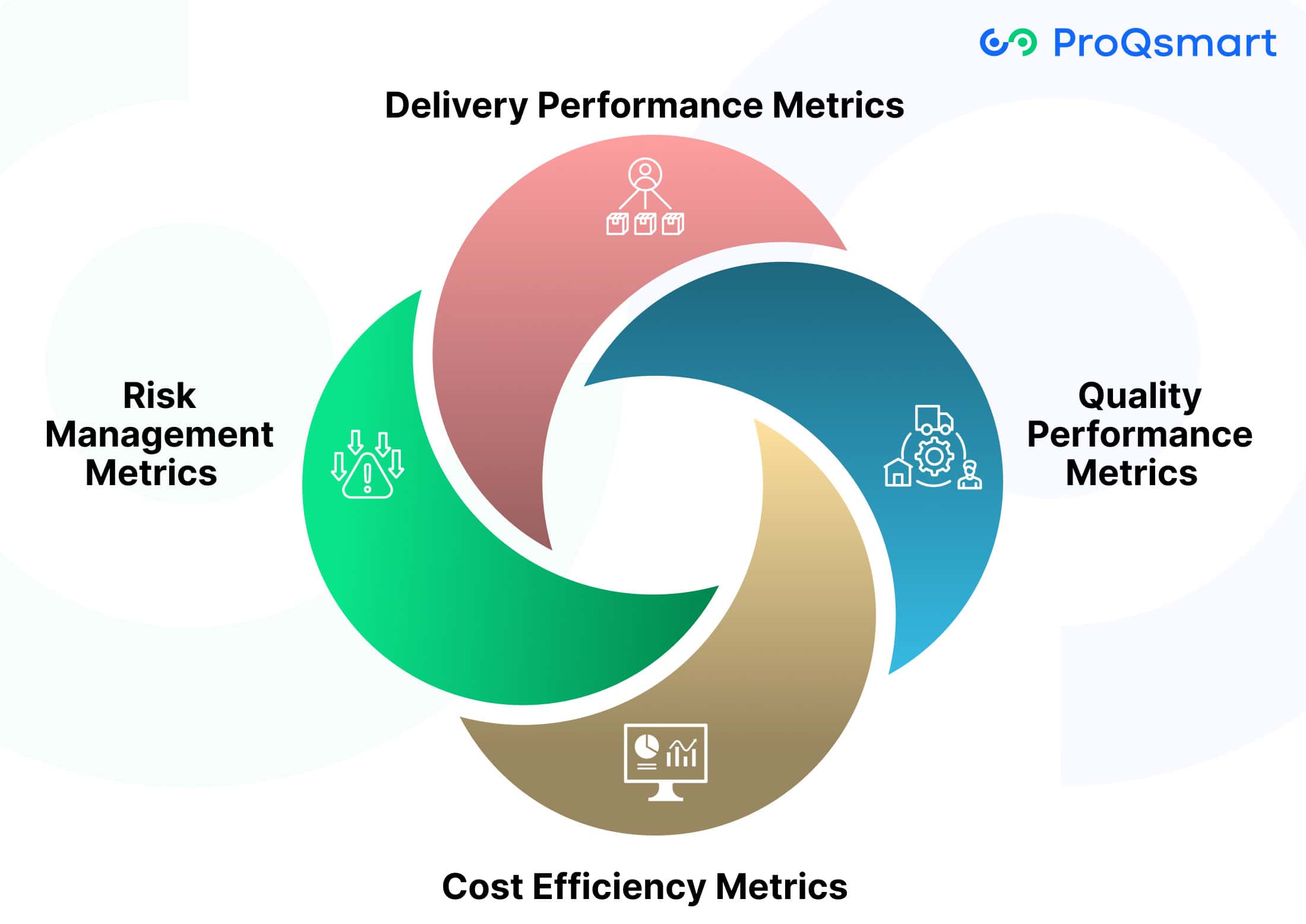

KPIs and Metrics for Supplier Management

Good supplier management comes down to having the right KPIs that you can measure to evaluate supplier performance and improve it. By leveraging effective supplier management processes and using data-driven insights, organizations can better align their operations with strategic supplier relationships, identify and mitigate supply risk, and promote ongoing improvement.

Delivery Performance Metrics

Suppose you are considering a supplier’s delivery performance metrics. Metrics such as on-time delivery rate and supplier lead time give you clear insight into how well your suppliers are meeting timelines contracted on.

The on-time delivery rate measures the percentage of orders completed by suppliers on time. Supplier lead time measures the number of days it takes from when you order a part to when it ships. By establishing clear expectations for delivery from the beginning, you further reinforce accountability and avoid delays, keeping business operations flowing without a hitch.

Quality Performance Metrics

Tracking a full suite of quality metrics, from defect rate to customer complaints, identifies areas for continuous improvement. The defect rate simply measures the percentage of inferior quality products or services delivered, and customer complaints provide insight into end-user satisfaction.

To take one example, a 15% reduction in customer warranty claims over a six-month period is proof that quality is improving. Proactive continuous improvement initiatives, driven by dynamic metrics, form a bridge that empowers suppliers to increase product reliability and improve service levels.

Cost Efficiency Metrics

While cost efficiency inevitably continues to be a key pillar of supplier management, metrics such as total cost of ownership (TCO) evaluate not only the direct costs involved, but the indirect costs associated with procurement as well.

ProQsmart’s cost savings tools such as AI driven analysis and vendor-initiated reengineering activities all lead to measurable savings while enhancing the negotiation process to save even more. Achieving a 10% price saving by means of reengineered processes, for example, saves money without compromising quality and improves operational budgets.

Risk Management Metrics

Having a successful supplier risk management strategy includes monitoring compliance and risk KPIs to prevent disruptions before they start. These impacts include metrics such as supplier compliance rates and contract adherence which keep suppliers accountable to the standards they should be meeting.

ProQsmart’s automated workflows and real-time tracking tools improve transparency. This allows companies to make deeper risk determinations and avoid reputational, operational, and financial risks.

Conclusion

Effective supplier management is crucial for achieving optimal manufacturing outcomes. By fostering strong relationships, enhancing product quality, and maintaining predictable workflows, organizations can ensure long-term growth and resilience. Clear communication, KPI tracking, and the strategic use of supplier management platforms are key to building a robust system that supports these goals.

Supplier management platforms like ProQsmart make these efforts easier by saving time and providing a more data-rich experience. With advanced tools, you gain greater control over supplier performance and can make data-driven decisions. Whether you’re refining existing processes or starting anew, investing in improved supplier management will yield significant returns.

Evaluate your current processes, engage with your team, and explore how ProQsmart can support your goals. Book a demo with ProQsmart to discover how their innovative solutions can help you streamline supplier relationships, enhance collaboration, and drive business success.