Supplier management is the process of managing and maximizing vendor partnerships, to create dependable supply chains, cost-effective manufacturing, and assurance that products meet expectations. Through smarter supplier management, you’ll enhance supplier collaboration, boost procurement efforts, and avoid disruptive risks to the supply chain.

This phased approach is key to continuing business as usual. Beyond saving taxpayer money, it drives forward large-scale strategic objectives, particularly in industries such as manufacturing and construction, where precision and punctuality are crucial.

Supplier management empowers you to harness data-driven insights and technology. It enables you to set proper performance criteria, negotiate more favorable terms, and ensure alignment with your organization’s goals.

As businesses face increasing complexity in supply networks, mastering supplier management becomes essential for achieving operational excellence and sustainable growth. The following sections dive into actionable strategies and supplier management best practices to help you develop stronger relationships with your suppliers.

Why Supplier Management Matters in Manufacturing Industry?

In manufacturing, effective supplier relationship management becomes critically important to maintaining operational efficiency and product quality. Developing positive supplier relationships raises the bar on quality expectations, leading to improved customer fulfillment. Bringing in organized, consistent supplier management processes helps demonstrate adherence to regulations, accelerating success in a highly competitive market.

Ensure Product Integrity

Quality assurance has always been the core of manufacturing, where supplier quality directly translates to product integrity. Supplier management, with thorough quality assurance inspection and performance monitoring processes, keeps suppliers aligned with goals for producing high-quality parts.

A simple example would be tracking supplier defect rates, which could help avoid costly production delays or recalls. Detailed quality expectations, defined within contracts, establish clear guidelines for suppliers and ongoing evaluations ensure any deficiencies are spotted.

ProQsmart makes this process a breeze with automated supplier performance monitoring, allowing businesses to focus on delivering consistent, quality products every time.

Boost Customer Satisfaction

Getting high-quality products out on schedule builds customer confidence and allegiance. That’s where supplier management really shines, by mitigating delays and providing consistent quality and reliability.

Data analytics tools, such as those found within ProQsmart, help manufacturers better understand customer preferences, enabling them to make smarter, data-driven supplier changes. Collecting feedback will give you specific information to help improve a supplier’s performance.

Improved communication lines help to make sure any customer complaints or issues are dealt with quickly, further promoting customer satisfaction.

Maintain Regulatory Compliance

Compliance with industry regulations is a must in the manufacturing world. Supplier compliance audits, integration of supplier platforms and supplier collaboration reduce risks of non-conformance.

ProQsmart’s transparency as well as auditable sourcing data make regulatory compliance easy to demonstrate. Documenting compliance efforts provides even more proof of accountability which is key when attempting to evade legal or financial consequences.

Challenges involved in Supplier Management

Balancing multiple priorities and addressing operational inefficiencies while fostering strong supplier relationships makes effective supplier management a daunting task. Recognizing these challenges is key to optimizing supplier performance and avoiding supply risk.

1. Inconsistent Supplier Performance

Poor supplier performance can lead to major production interruptions. Continuously monitor key performance indicators (KPIs). Supply chain management is all about finding problems before they become a crisis, like late deliveries or lack of quality control.

Corrective action plans paired with open dialogue enable us to tackle the root causes together. Regular performance reviews can identify gaps, allowing for focused improvement initiatives that foster long-term supplier reliability.

2. Limited Visibility into Processes

Without better visibility into supplier operations, it makes supplier management even harder to make informed decisions. Only 15 percent of these companies are able to view over 50 percent of their Tier 1 and Tier 2 suppliers.

That’s why investing in the right technology has never been so important. Real-time dashboards and analytics to improve transparency combined with regular audits to identify and eliminate inefficiencies should become the norm. Transparent communication fosters trust, allowing us to preempt potential disruptions.

3. Inefficient Manual Tracking

Manual tracking is doomed to be late and flawed. Automating these processes with robust software solutions not only improves accuracy, but saves significant time.

Training teams on digital tools to maximize efficiency with regular evaluations guarantees ongoing success. Adopting faster and automated business appraisal systems, for example, can help cut down on that time and benefit the 35% of firms that spend 5-6 weeks per appraisal.

4. Difficulty in Risk Assessment

With 62% of businesses doubting their risk monitoring programs, establishing a robust framework is essential. Predictive analytics can anticipate supply chain disruptions, while regular risk assessments keep strategies aligned with market conditions.

Collaborative mitigation efforts strengthen supplier relationships and safeguard operations.

5. Communication Barriers

More than that, communication is an ongoing challenge, as 98% of suppliers request improved client communications. Through digital platforms, suppliers can easily track and communicate with stakeholders, allowing questions and issues to be quickly resolved.

Consistent communication through periodic meetings and feedback suggestions create healthier supplier relationships, as 52% of suppliers claim to have trouble discussing issues.

6. Lack of Supplier Collaboration

When we work together, we create new ideas and mutually beneficial outcomes. Collaborative efforts and open communication build camaraderie.

Rewarding proactive suppliers with positive acknowledgment encourages future participation. By creating an environment of collaboration, we bring everyone’s goals into alignment to drive the best possible results for both clients and suppliers.

7. Managing a Diverse Supplier Base

While diverse suppliers can offer unique strengths to meet challenges, they need focused strategies to leverage their strengths effectively. Organizing suppliers into specific categories makes oversight easier while still keeping everyone welcome.

Conducting regular diversity evaluations increases the importance of diverse supplier utilization, improving resilience and demonstrating values to constituents and customers.

8. Regulatory Compliance Issues

Even compliance challenges require never-ending focus. Regular training and compliance audits can close gaps, and involving legal teams in supplier vetting processes keeps companies up-to-date with changing regulations.

By taking proactive compliance measures, you mitigate risks while creating a level of confidence with your suppliers.

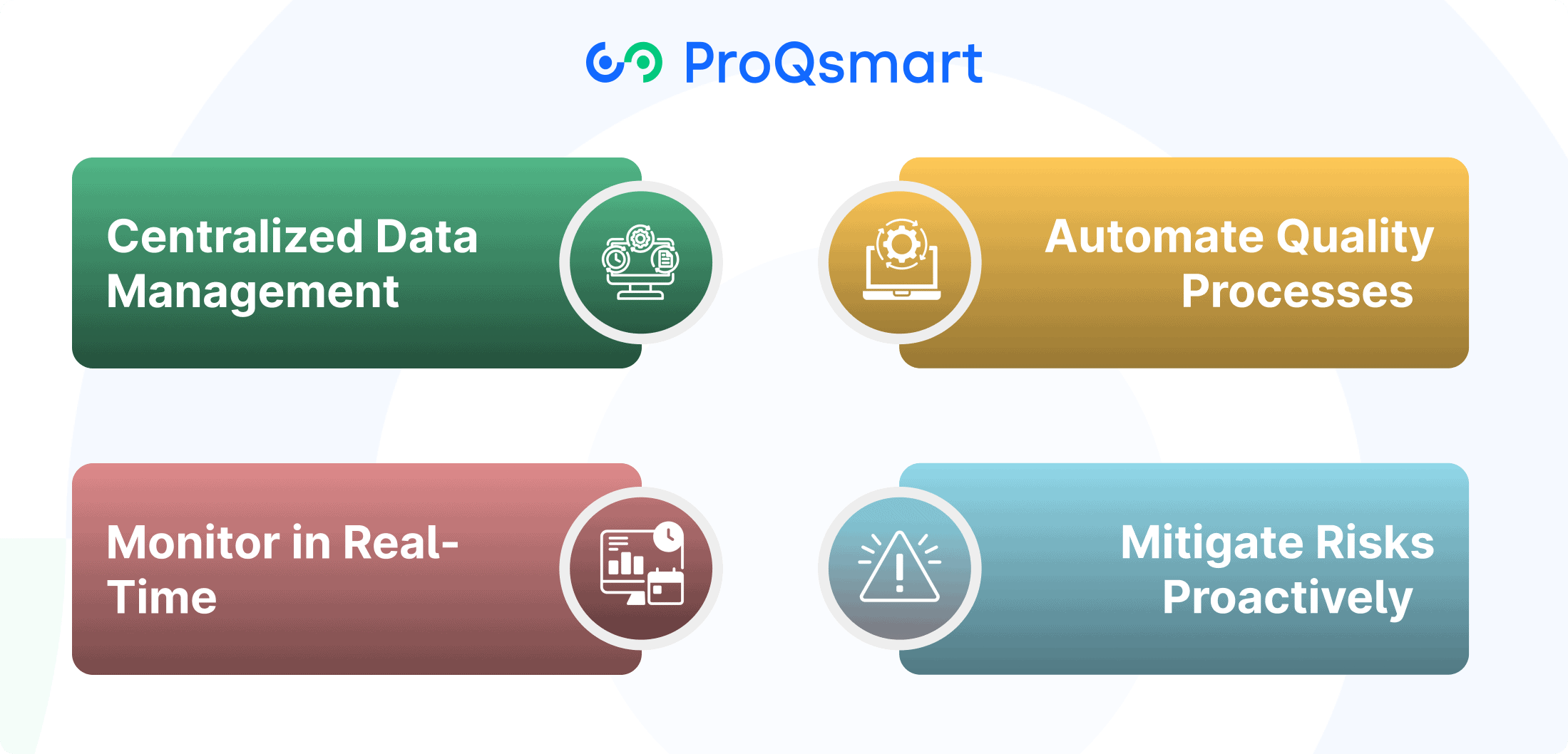

Benefits of Supplier Management Solutions in Manufacturing Industry

Supplier management solutions meet the most pressing challenges in manufacturing today. They improve day-to-day operational efficiency, maintain compliance, and even foster collaboration among suppliers. From simplifying complex processes to minimizing administrative burden and enhancing supply chain resilience, these solutions empower manufacturers to drive sustainable growth.

Below, we explore the core benefits:

|

Benefit |

Key Advantage |

Outcome |

|---|---|---|

|

Centralized Data Management |

Consolidates supplier information |

Enhanced visibility and informed decisions |

|

Automation of Quality Processes |

Reduces manual errors and streamlines audits |

Time savings and improved quality control |

|

Real-Time Monitoring |

Tracks supplier KPIs |

Ensures compliance and timely deliveries |

|

Risk Mitigation |

Identifies and addresses vulnerabilities |

Increased supply chain resilience |

Centralized Data Management

Having suppliers’ product information and compliance records easily accessible—with one click or search—from one platform like ProQsmart saves manufacturers time and mitigates risk. With cloud-based solutions, supplying/shipping status updates are in real time, thus minimizing errors and resulting discrepancies.

ProQsmart’s supplier information management system effectively organizes and maintains current supplier data, allowing for more operational efficiency within the business. For example, a manufacturer using centralized data would be able to quickly judge supplier performance trends. This visibility drives strategic decision-making and reduces cycle times.

Automate Quality Processes

Audit management Automation removes manual inefficiencies by centralizing and simplifying the process for audits and tracking non-conformance. With ProQsmart’s automated workflows, corrective actions are addressed swiftly, minimizing costly disruptions to manufacturing.

Educating teams on these systems helps manufacturers acquire the most precise data in a timelier manner. In turn, they improve product quality and increase regulatory adherence.

Monitor in Real-Time

Real-time monitoring through dashboards enables manufacturers to track KPIs, ensuring suppliers meet performance metrics consistently. With ProQsmart’s performance monitoring tools, you get alerts for deviations, enhancing transparency and accountability.

By incorporating performance data into supplier reviews, companies can better align their operations with their sustainability goals and avoid future expensive disruptions.

Mitigate Risks Proactively

Risk analysis and supplier evaluation, with the support of risk management solutions such as ProQsmart, are key to recognizing vulnerabilities. When a manufacturer takes a proactive approach to collaboration with suppliers, risks are mitigated and the supply chain becomes much stronger.

For example, contingency measures created through ProQsmart’s risk management plans provide business continuity during unexpected disruptions.

Strategies for Quality Assurance

Quality assurance in supplier management is key to protecting your operational excellence and customer satisfaction in the long run. Supplier quality management (SQM), the subset of supplier relationship management, is about judging a supplier’s capacity to deliver on your organization’s objectives seamlessly. Setting agreed upon quality benchmarks, building lasting partnerships, and applying well-defined, repeatable processes are key to making this depth of collaboration possible.

Here, we present five proven strategies to maximize quality throughout your supply chain.

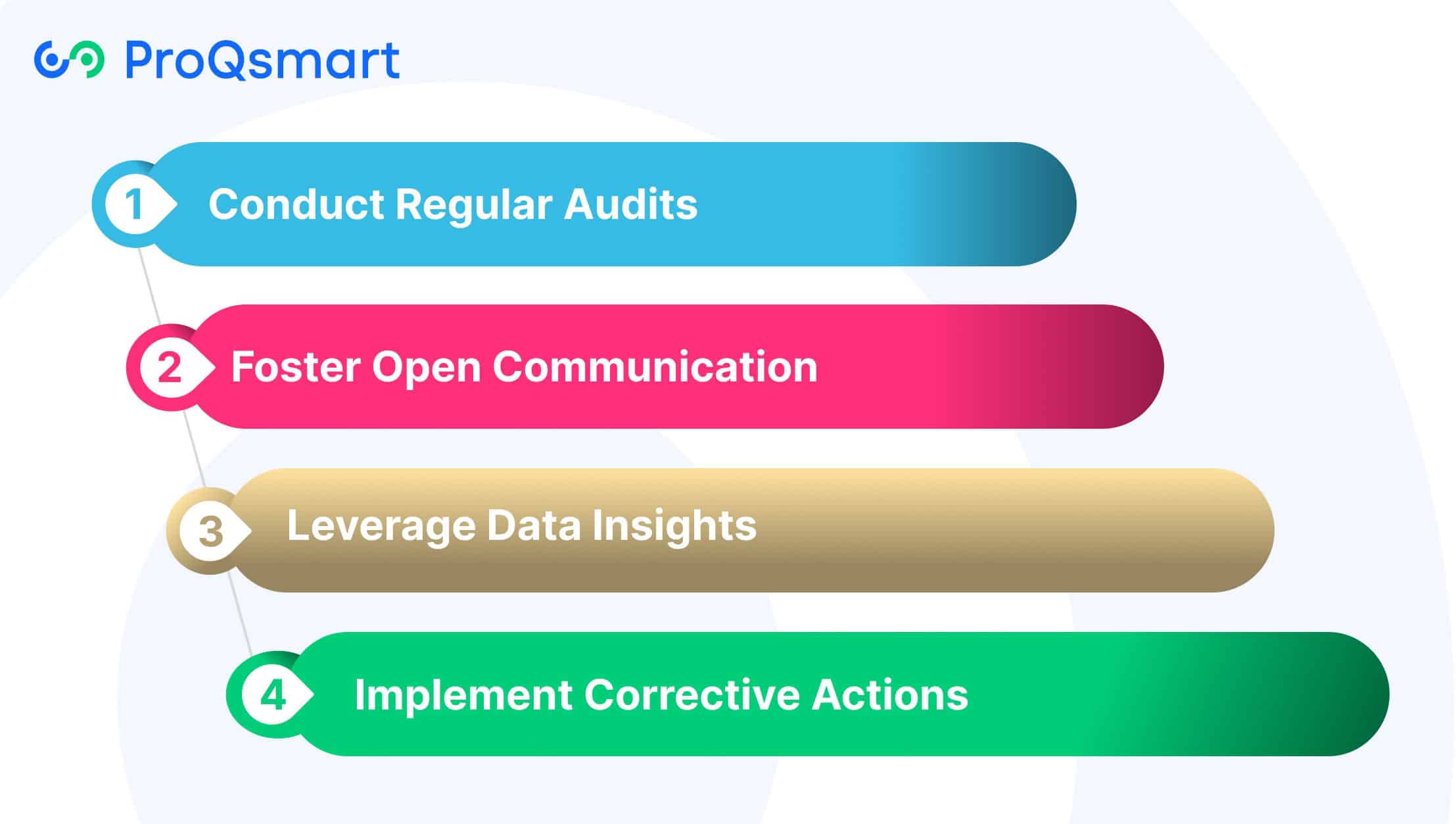

Conduct Regular Audits

Regular audits are essential for assessing supplier compliance and performance consistency. Scheduling periodic evaluations ensures adherence to quality standards and identifies areas for improvement. Audit criteria should align with industry benchmarks, such as supplier capacity, financial stability, and technical support.

Sharing audit results with suppliers promotes transparency and a collaborative improvement process. For example, using scorecards helps track supplier performance against predefined metrics, like delivery reliability and cost efficiency. Follow-up assessments ensure corrective actions lead to measurable improvements.

Foster Open Communication

Communication is key when it comes to building robust supplier relationships. Holding routine discussions to crystalize quality goals and barriers fosters a productive culture. Encouraging feedback facilitates mutual growth while addressing concerns early.

For example, suppliers are usually the best sources of ideas for product and process improvements that save money for both organizations. An environment of open dialogue creates a culture of trust and helps ensure quality objectives are shared across the entire supply chain.

Leverage Data Insights

Data analytics is changing the game in looking at supplier quality. Tools like ProQsmart streamline procurement by offering real-time data on supplier performance, enabling informed decisions. AI-powered features like supplier performance monitoring, compliance tracking and more make it easy to follow trends and optimize strategies with ProQsmart.

For instance, geocoding on-time delivery rate data can identify problem areas and lead to targeted, effective fixes.

Implement Corrective Actions

An organized method of addressing quality shortcomings is applied across the board, creating a system of accountability. Working with suppliers to correct defects immediately prevents greater interruptions.

Along with improving internal operations by documenting corrective actions taken, which would improve any future efforts, those actions greatly improve future compliance. Continual monitoring of outcomes via regular follow-up checks creates a quality framework that will last.

Emerging Trends in Supplier Management

Supplier management is changing very quickly, driven by technology, sustainability, and ethical practices. By tackling the increasing intricacies of supplier relationship management and the expectations of today’s global supply chain, these trends are helping organizations improve both efficiency and accountability.

AI and Machine Learning Integration

The adoption of AI and machine learning is revolutionizing supplier management by providing actionable insights. Predictive analytics tools identify trends in supplier performance, enabling proactive decision-making. Early AI adopters in supply chain management have already achieved a 34% cost reduction, showcasing the tangible benefits of these technologies.

Machine learning algorithms help uncover patterns and flag anomalies, ensuring supplier reliability. AI-driven platforms like ProQsmart optimize supplier selection by analyzing historical data and aligning procurement with organizational budgets.

With features such as supplier performance monitoring and compliance assurance, businesses can regularly assess and refine their strategies for maximum impact.

IoT for Real-Time Tracking

Along with industrial IoT (IIoT) technologies, these tools offer a new level of transparency into supplier operations. Sensors with real-time visibility monitor stock levels and delivery schedules, enabling a more efficient “just-in-time” or “just-right” inventory approach.

As an illustration, 54% of firms using IIoT say they have better supply chain efficiency. Information collected through the IoT pinpoints inconsistencies, allowing changes to be made instantly.

Through ongoing collaboration with their suppliers to incorporate new IoT tools, even more efficiencies can be built into workflows and operative transparency established.

Focus on Sustainability

Sustainability is increasingly at the heart of supplier management, as companies are embracing sustainable, environmentally friendly practices and monitoring supplier practices against sustainability standards. Correspondingly, companies are clearly acting, in part, to get ahead of the public’s call for more transparency with moves towards digital product passports and environmental reporting.

Exchanging best practices creates a shared sense of purpose among suppliers and helps deepen those partnerships with today’s sustainable sourcing goals.

Ethical Sourcing Practices

Ethical sourcing is a crucial aspect of supplier relationship management, ensuring that companies maintain strong relationships with their strategic suppliers by honoring labor standards and human rights. By implementing systematic supplier management processes, including regular audits and proof of non-discrimination practices, organizations can enhance transparency and protect their reputation.

In the context of multi-shoring strategies, these ethical practices play a vital role in mitigating supply risk across diverse supplier networks. This not only aids in compliance but also fosters ongoing relationships with important suppliers, ultimately supporting the enterprise’s commitment to ethical business operations.

Conclusion

Supplier management sets the stage for successful outcomes across the manufacturing sector. Delivering high quality, achieving cost savings, ensuring work flows smoothly all point toward a focus on strong supplier relationships. Addressing issues before they become drawbacks, such as poor communication or lack of quality, keeps the project moving forward. Implementing and enforcing strategies that are known to work, including nothing less than regular audits and performance metrics, ensure quality is maintained.

Moving to new solutions, including supplier management software and innovative data analytics, streamlines cumbersome workflows and increases productivity. Monitoring the latest trends, such as sustainable sourcing practices and digital innovations, will ensure that your sourcing initiatives remain competitive and responsive.

ProQsmart provides cutting-edge tools to optimize supplier management processes and drive sustainable value. Book a demo today to position your business for long-term success!