In the manufacturing industry, effective procurement is essential for maintaining operational efficiency and controlling costs. One of the most effective tools in this process is the Request for Quotation (RFQ), which invites suppliers to submit their best prices for specific goods or services. RFQs play a crucial role in enhancing supplier selection by fostering competitive bidding and providing a structured framework for evaluating supplier proposals.

By utilizing RFQs within an e-sourcing framework, organizations can streamline their procurement processes, ensuring transparency and consistency throughout. This method is particularly beneficial for projects with well-defined specifications, allowing manufacturers to receive accurate estimates from potential vendors. Furthermore, RFQs help mitigate risks associated with supplier selection by enabling apples-to-apples comparisons of offerings, thus supporting informed decision-making.

As manufacturers increasingly embrace digital tools, integrating RFQs into e-sourcing strategies not only improves efficiency but also enhances the overall quality of supplier relationships. In this article, we will explore how RFQs enhance supplier selection in e-sourcing for manufacturing, highlighting best practices and the advantages of adopting this approach.

Why RFQs are Important in Manufacturing?

Securing Competitive Pricing

Manufacturers are huge on RFQs because they need competitive pricing on raw materials and components. For instance, a construction company might release an RFQ document to find steel beams for a new high-rise building. By obtaining numerous price quotes, the firm can choose a potential vendor that produces the highest quality at the best possible value, keeping in line with project budgets. This practice is especially vital for businesses requiring consistent supply chains for standard products, ensuring cost control and financial stability.

Managing Costs and Budget Planning

RFQs provide a structured approach that supports the manufacturer’s ability to minimize costs. Thoroughly detailed written responses allow procurement teams to anticipate costs and ensure that project budgets align with broader fiscal priorities. In the processing phase of an RFQ, it’s essential to actively compare supplier proposals. By taking this approach, you’ll identify opportunities to save costs and find the best quality materials, ultimately enhancing the bidding process.

Maintaining Quality Standards

Quality assurance is another significant benefit of RFQs. By evaluating vendor capabilities, manufacturers can ensure their suppliers meet stringent production requirements. This step is crucial in industries like aerospace, where precision and reliability are paramount, ensuring that all technical specifications are met effectively.

How to Write an Effective RFQ

A well-prepared RFQ (Request for Quote) ensures a smooth procurement process by clearly communicating project needs and expectations to prospective vendors. Providing the most detailed and relevant information upfront in an RFQ document, such as a pricing table, is a time-saver. It means you’re setting yourself up to get cost-effective, valuable outcomes. Below, we demystify these key elements and explain their purpose in creating a successful RFQ.

"Now you don’t have to worry about drafting your RFQ! We’ve got you covered with our customizable RFQ template. Download it today and simplify your procurement process with ease!"

Include an Invitation and Summary

Your invitation can be direct and to the point about what the RFQ document is seeking, yet still be creative, professional, and exciting. For example, a construction project RFQ could describe the types of materials to be provided or the need for subcontractor services. Including a short project summary gives suppliers important context, including high-level information on project requirements, deliverables required, and how you will evaluate proposals using the RFQ format.

Provide Business and Project Details

Describe your firm’s capacity and vision for the RFQ document. This should include a detailed description of the project, primary goals and objectives, and any special or specific needs. Including a Bill of Quantities (BOQ) can be expensive in construction, but it helps the vendor understand the necessary materials and labor. Providing this extensive context aids suppliers in crafting their proposals to meet your procurement needs and expectations.

Specify Vendor Requirements Clearly

Clearly outline the qualifications you expect potential vendors to have, whether that’s specific certifications, years of experience, or technical know-how. For example, requiring a Statement of Qualifications (SOQ) ensures that only the most qualified suppliers respond to your RFQ documents. Unambiguous requirements make it easier to compare bids while honing in on vendors who can actually deliver value.

Outline Specifications and Terms

Incorporate specific product or service requirements, including delivery schedules and quality requirements, within your rfq documents. For example, by specifying the material grades or service levels required, it reduces the chance for misinterpretation. Clear, specific terminology and guidelines help potential vendors know what you expect, which helps everyone get on the same page.

Add Pricing Templates or Tables

Incorporating clear, structured pricing templates in your RFQ documents allows for apples-to-apples comparisons of vendor responses, streamlining the bid process. This approach not only simplifies the comparison of costs but also emphasizes that while cost is important, 80% of RFQs are awarded based on overall value, making it essential to balance cost with quality expectations.

Define Timeline and Deadlines

Establishing firm submission deadlines and evaluation timelines is crucial in the procurement process. For smaller scale tasks, two weeks is appropriate, but this might need to be modified for larger, more complex projects. Clear timelines establish a sense of urgency, increasing response rates and ensuring successful RFQ submissions.

Establish Evaluation Criteria

Include quantifiable evaluation criteria in the rfq documents so people are evaluating apples to apples and not oranges. For instance, score bids not just on price, but also on historical experience, proposed methodology, and adherence to technical specifications. Having clear criteria helps guide decision-making and provides greater transparency in the procurement cycle.

Streamline with ProQsmart

Leveraging technology such as ProQsmart to streamline the RFQ process makes it easier to manage procurement cycles. ProQsmart’s AI-driven procurement platform enhances the bidding process through e-tendering and workflow automation, increasing transparency in decision-making while ensuring compliance with technical specifications and controlling amendments to RFQ documents in real-time.

"Now you don’t have to worry about drafting your RFQ! We’ve got you covered with our customizable RFQ template. Download it today and simplify your procurement process with ease!"

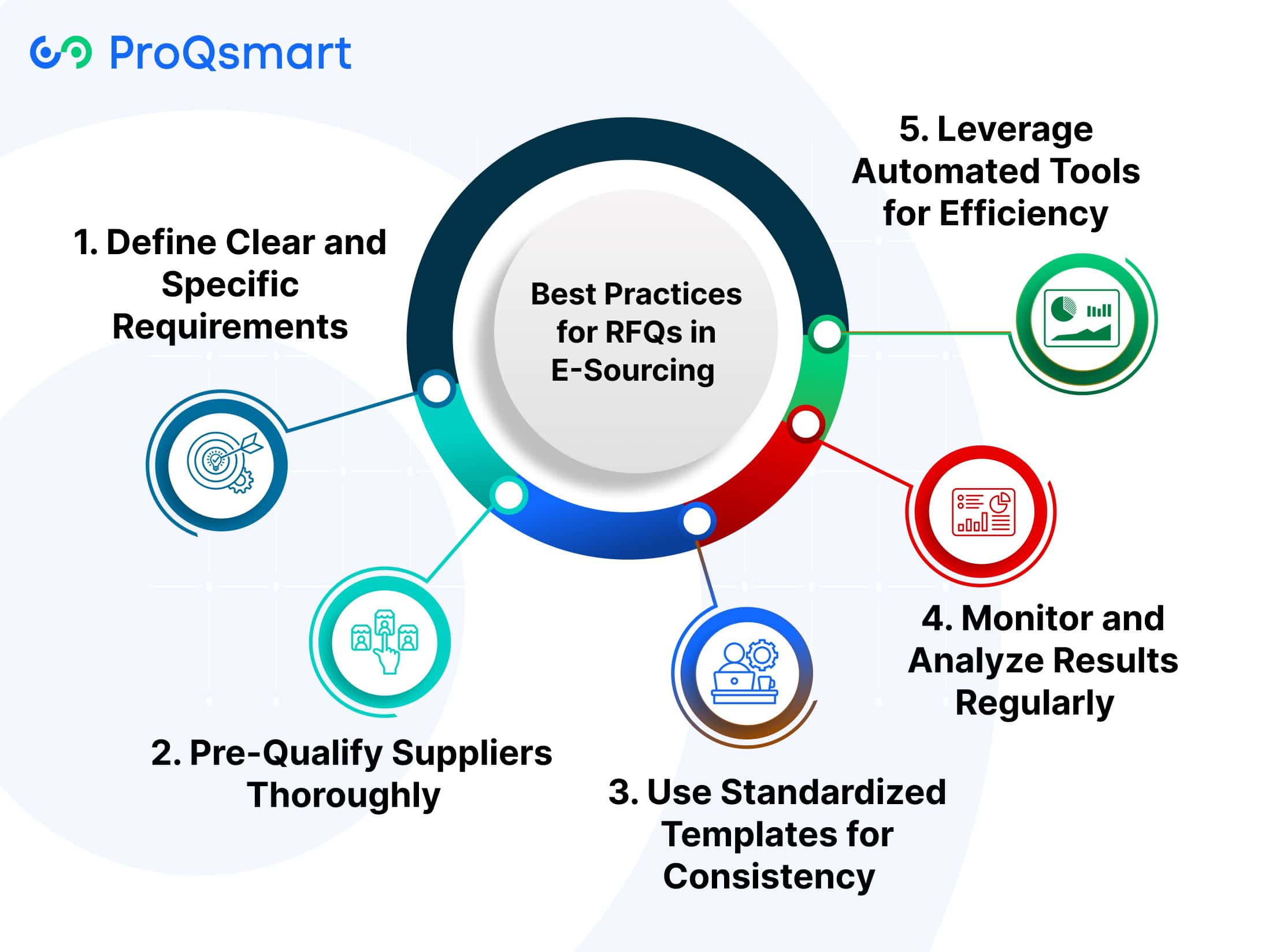

Best Practices for RFQs in E-Sourcing

Request for Quotations (RFQs) in e-sourcing are crucial for winning competitive bids and fostering collaborative relationships with suppliers. To maximize the return on procurement investment, companies should adopt a systematic view of the bidding process. Implementing a well-structured rfq template can significantly enhance the effectiveness of RFQs.

1. Define Clear and Specific Requirements

Well-defined requirements are the bedrock of a successful RFQ process. Articulating project goals and expectations ensures suppliers understand the scope, reducing ambiguity. For instance, when you specify material grades, delivery schedules, or compliance standards, you receive bids that best suit your needs. This precision draws in better qualified suppliers, raises the quality of bids received, and speeds up the decision process. To take it a step further, including an RFQ document helps further format and guide vendors.

2. Pre-Qualify Suppliers Thoroughly

By pre-qualifying potential vendors, you reduce risk by only inviting those that meet your requirements and criteria to submit bid responses. Evaluating financial stability with two to three years of data, compliance history, and performance records builds confidence in supplier capabilities. In the case of construction projects, pre-qualified suppliers are more likely to meet deadlines, leading in quality benchmarks and cutting down on costly project rework.

3. Use Standardized Templates for Consistency

Standardized RFQ templates play a crucial role in the bidding process by ensuring clarity and saving time. These templates guarantee that each request is uniform, allowing prospective vendors to respond with the most effective bid responses. A well-structured RFQ document simplifies the procurement cycle, whether for smaller RFQs with a two-week timeline or complex projects requiring detailed technical specifications. Tools like ProQsmart enhance this efficiency further.

4. Monitor and Analyze Results Regularly

Tracking and analyzing RFQ documents reveals patterns and opportunities for growth in the procurement cycle. Metrics such as response time, cost savings, and supplier performance provide the insights needed to make impactful decisions. In fact, analyzing which RFQs are non-competitive—close to 8 out of 10 times—allows for a more effective bidding process to be developed.

5. Leverage Automated Tools for Efficiency

Automated tools such as e-sourcing platforms enhance the bidding process by minimizing the risk of human error and accelerating the evaluation of bid responses. Moreover, integration with procurement management software centralizes all RFQ documents, creating better transparency and workflow, ultimately propelling greater procurement performance and improving the overall project budget.

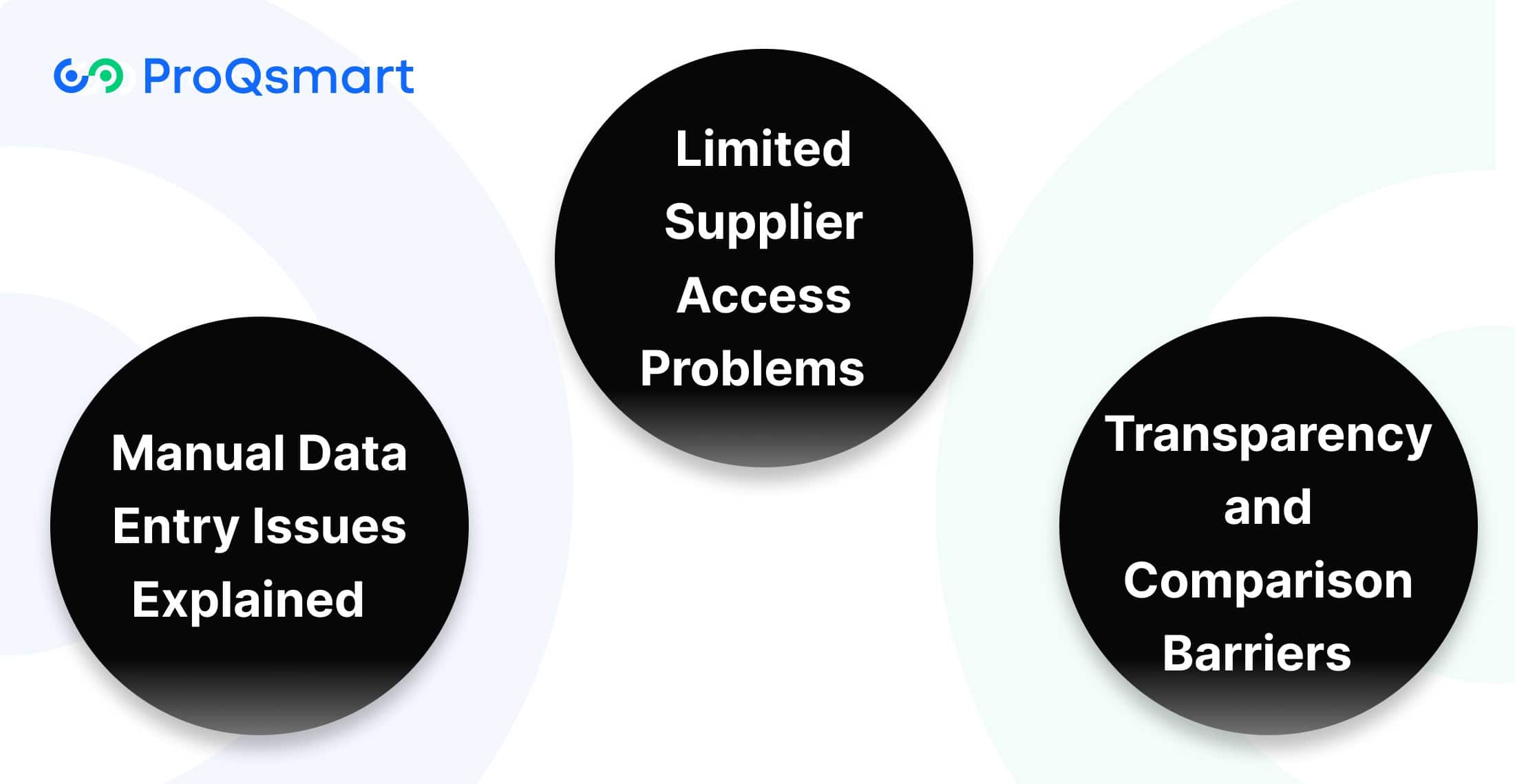

Common Challenges in RFQ Processes

Manual data entry pitfalls, lack of access to suppliers, and transparency deficiencies all serve as major barriers in the RFQ process. These hurdles can significantly impact the effectiveness and efficiency of bid responses and procurement cycles. Overcoming these common challenges is key to ensuring successful RFQs and establishing lasting partnerships with potential vendors.

Manual Data Entry Issues Explained

While manual data entry may sound like an easy task, it poses risks that jeopardize the integrity of the RFQ process. Mistakes such as typographical errors or missing information can adversely affect supplier scores, leading to poor decisions. A single error in the pricing table can dramatically skew the cost comparison, potentially causing you to select a suboptimal supplier. Astonishingly, almost 40% of contractors fall flat due to clerical mistakes in creating RFQ documents. These errors not only push back the procurement timeline but also increase administrative costs substantially.

Automated solutions can be key in addressing these challenges. Tools that digitize and streamline data entry significantly reduce the likelihood of human error skewing supplier evaluation metrics. By collecting historical financial data with specialized software, businesses can improve the accuracy and efficiency of their bidding process when creating budgets. Reviewing at least two to three years of historical records enhances the overall budgeting cycle.

Limited Supplier Access Problems

Restricted access to a diverse supplier base creates competition gaps, limiting opportunities to negotiate better pricing or secure higher-quality products

Increasing supplier networks is key to addressing these barriers. Procurement teams are using these new digital platforms and supplier discovery tools to reach a far greater pool of qualified vendors. This method encourages robust competition, resulting in better pricing and more quality outcomes. Accessing suppliers In fact, with the right strategy and tools, optimizing supplier access can increase win rates by an incredible 31%.

Transparency and Comparison Barriers

Transparency, ultimately, is the cornerstone of an effective RFQ process. Obstacles like vague evaluation criteria, undisclosed costs, or lack of communication make it difficult for suppliers to compare options. These challenges can create a lot of unnecessary noise and confusion, resulting in misaligned expectations between procurement and suppliers.

Clear and consistent communication with applicants can go a long way towards removing these barriers. For instance, giving suppliers standardized templates to respond to and outlining detailed evaluation criteria makes for apples-to-apples comparisons. Transparency goes beyond easing the decision-making process and helps build confidence, which is crucial in any supplier relationship.

How E-Sourcing Enhances the RFQ Process: Overcoming the Challenges

E-sourcing has revolutionized the RFQ process, leveraging technology to overcome procurement’s most prevalent pitfalls. Companies are using solutions that streamline workflow through automation, facilitate live bidding, and keep all data in one place. As a consequence, they are saving time and increasing efficiency with expedited workflows and enhanced results. These innovations streamline the bidding process, cut costs, and improve decision-making precision, powering efficiency across every sector in the supply chain.

Automation of RFQ Distribution Tasks

Automation makes RFQ distribution much more efficient, allowing procurement teams to reach dozens or hundreds of potential vendors in just a few clicks. Automated notifications and reminders keep suppliers on track to respond on time, preventing unnecessary hold-ups. From automatically scheduling RFQs, including the pricing table for comprehensive bids, to sending them to global suppliers across time zones, e-sourcing boosts the RFQ process. By minimizing administrative tasks such as posting RFQs and creating follow-ups, teams will have more capacity for strategic sourcing initiatives. This significantly speeds up the bidding process and increases productivity by leaps and bounds.

Real-Time Bidding Capabilities Explained

By enabling suppliers to outmaneuver one another through real-time bidding, healthy competition is enforced between suppliers. Procurement teams are empowered with instant pricing updates, which unlocks a dynamic, real-time negotiation atmosphere. For instance, parallelized e-auctions, a feature included in platforms like ProQsmart,allow companies to quickly lock down the best pricing across the board. This added functionality creates a clear trail of transparency and narrows supplier focus, maximizing cost savings while reinforcing supplier connection.

Centralized Data Management Advantages

Centralizing supplier information into a centralized system makes rfq documents more easily accessible and organized. Procurement teams can track all bids, contracts, and supplier performance in real time, which eliminates costly errors and improves internal collaboration. ProQsmart’s AI-powered tools, like our advanced subcontractor tendering and pricing table tools, facilitate compliance and keep everything above board. This level of detailed organization promotes a deeper alignment between organizational budgetary objectives and procurement strategy.

Automated Quote Comparison Features

Automated tools save the time of manually comparing bids by evaluating pricing information, delivery terms, and other factors at a glance. This prevents humans from making errors and allows for apples-to-apples comparisons, resulting in smarter decisions. Combined with ProQsmart’s automated workflows, from drag-and-drop RFQ document creation to analysis, the bidding process cycle times are reduced significantly, allowing for faster and more informed decision-making. By identifying the most cost-effective suppliers, businesses can achieve up to 20% cost savings within the first year of implementation.

Impact of RFQs on Supplier Selection

RFQs profoundly impact supplier selection strategies by promoting transparency, efficiency, and collaboration in the bidding process. Their organized methodology allows procurement experts to deliver the best results by utilizing rfq documents, embracing data-driven decision-making, and fostering better supplier relationships.

Improved Supplier Relationships

RFQs are an essential, foundational tool for effective communication between buyers and suppliers. When they issue clear, detailed specifications and requirements from the start, they establish a base of mutual understanding. Suppliers receive greater clarity on performance expectations, allowing them to better tailor their offerings to what the organization truly needs. For instance, specifying delivery timelines or quality standards helps set clear expectations from the start, minimizing confusion later on.

This important standardized communication builds trust and collaboration. Suppliers turn into more dependable partners, leading to improved supply chain performance over time. In the long run, these partnerships develop into strategic alliances, with suppliers contributing in a more proactive way to innovation and cost-effective solutions. Tools such as ProQsmart enable this by providing a shared dashboard that strengthens supplier relationships with proactive, real-time collaboration, and performance identification.

Better Decision-Making Processes

The RFQ process is a goldmine of actionable data, particularly when utilizing an rfq template to streamline submissions. This information empowers procurement professionals to evaluate suppliers on various factors, including cost, quality, and delivery schedule. For instance, competitive bids ensure buyers can objectively select suppliers capable of meeting requirements while avoiding overpayment, often reducing costs by up to 20%. ProQsmart’s AI-driven analytics further simplifies this by automating bid comparisons and aligning procurement with your organization’s goals.

Increased Competition Among Vendors

RFQs motivate suppliers to compete hard—putting their best foot forward in their RFQ proposals. This natural competition from the bidding process ensures suppliers strive for the buyer’s business with lower prices and better service, ultimately saving taxpayer dollars and delivering greater value. Using a standardized RFQ template, such as ProQsmart’s e-tendering feature, simplifies bid evaluation while offering the most transparent and efficient supplier selection, making the procurement cycle more efficient, saving both time and money.

Conclusion

RFQs are an essential part of the procurement process, allowing for easier supplier evaluation and helping to maximize taxpayer dollars by ensuring cost-effective decisions. Most importantly, creating comprehensive and thoughtful RFQs sets a precedent of transparency that creates better relationships with suppliers. E-sourcing tools streamline the process and minimize mistakes. They reduce errors, enabling your teams to break down silos created by miscommunication and delays. Beyond accountability, these tools increase space for more informed analysis, allowing companies to identify and choose the best partners and remain competitive.

Going through the process of refining RFQ strategies can help to set up future success. Comprehensive, well-thought-out RFQs save money, avoid increased risk, and lead to an overall more efficient procurement process. With the right tools and a meticulous approach, teams can realize more value from their strategic sourcing initiatives.

To maximize the benefits of your RFQ processes, consider integratingProQsmart’s innovative e-sourcing solutions. Our platform streamlines RFQ management, enhances supplier selection, and drives better procurement outcomes. Don’t miss the opportunity to elevate your procurement strategies—book a demo with ProQsmart today.