Effective supplier relationship management (SRM) is a cornerstone of successful construction procurement. In an industry where project timelines are tight and budgets are often constrained, maintaining strong relationships with suppliers is crucial for ensuring timely deliveries, managing costs, and maintaining quality standards. By leveraging SRM platforms, construction companies can significantly enhance their procurement processes. These platforms provide a centralized system for managing supplier interactions, tracking performance, and mitigating potential risks. This not only leads to improved operational efficiency but also fosters a collaborative environment where both parties can benefit from shared goals and innovation.

In this article, we will delve into the ways SRM platforms can transform construction procurement by streamlining supplier management, enhancing collaboration, and driving long-term success.

Role of SRM in Construction

Supplier Relationship Management (SRM) plays vital in navigating the specific challenges of the construction industry. Construction projects heavily depend on the complex network of supply chains. They rely on their suppliers to provide materials and services on time and on budget.

SRM offers a repeatable process to identify and manage these relationships, providing improved operations and an increase in overall project success.

Construction Industry Challenges

Fragmented supply chains and communication silos are a major barrier to success in construction. With disjointed timelines or lack of communication about deliverables, deadlines can be delayed or missed entirely, costing critical time to a project’s overall schedule.

SRM plays a role in supply chain disruptions, be it material shortages or logistical issues that cause lack of progress and additional costs. Competition between stakeholders, such as contractors, subcontractors, and suppliers, further adds to the complexity of needed coordination efforts.

Robust risk management is vital to overcoming these challenges, and SRM provides the proactive tools to do just that.

Benefits of SRM for Construction Projects

SRM is increasing supplier sustainability performance, saving money and increasing supplier efficiency in the process. Through encouraging innovation, it allows for suppliers to propose better products or approaches, resulting in a higher quality project.

Collaboration is another cornerstone of SRM, bridging silos and establishing a shared goal among project stakeholders. More efficient procurement processes, enabled by platforms such as ProQsmart, lead to more transparency, efficiency, and less waste.

For instance, ProQsmart’s supplier performance monitoring tool provides transparency and tracks suppliers’ progress toward goals, fostering trust and accountability.

Improving Project Outcomes with SRM

Maximizing project efficiency by aligning supplier capabilities with project requirements is critical for on-time delivery and overall customer satisfaction. SRM provides the necessary transparency and constant, real-time communication to avoid those same risks when it comes to miscommunication or performance lapses.

Through the centralization of all supplier data, SRM helps to drive smart decisions, reducing disruptions and increasing responsiveness on fast-tracked projects.

How to Develop a Robust SRM Strategy

Developing a successful SRM strategy requires attention on several areas that lead to productive collaboration. Focusing like this allows all the players to win together. When companies align supplier relationships with business goals, they can achieve stronger performance outcomes, minimize costs, and stimulate innovation.

Here are some actionable steps to develop an effective SRM strategy:

- Identify key suppliers based on their strategic importance.

- Set clear expectations and performance indicators for suppliers.

- Establish open communication channels for ongoing dialogue.

- Implement regular performance monitoring and feedback mechanisms.

Identify Key Suppliers

Identifying key suppliers starts with evaluating their impact on your business operations. Suppliers that consistently deliver quality, reliability, and value should be prioritized.

Strategic sourcing ensures a balanced supplier portfolio, reducing dependency on a single source and mitigating risks. For example, a manufacturer might focus on suppliers that provide critical raw materials to maintain production schedules.

Set Clear Expectations and KPIs

Suppliers will be able to align with your business objectives if you break down clear expectations into measurable KPIs. Metrics such as on-time delivery rates, quality acceptance rates, and cost performance create a culture of accountability.

Clear and transparent communication helps set those expectations so that everyone is on the same page, which builds trust and collaboration.

Establish Communication Channels

The more we interact, the more our relationships deepen and strengthen. Consistent communication via in-person meetings, digital engagement providing real-time information, and an iterative feedback loop are critical.

Platforms such as ProQsmart make collaboration much easier with collaborative e-tenders and performance monitoring to develop and improve your suppliers.

Implement Performance Monitoring

Regular performance measurement and monitoring holds suppliers accountable to the terms of the agreement. Data analytics can track delivery times, compliance, and overall performance, providing insights for improvement.

Swift communication fosters development and provides opportunities to refocus efforts before misalignment can snowball into miscommunication.

Foster Collaboration and Innovation

Building a collaborative economy improves productivity by making connections. Collaborative efforts, such as jointly developing sustainable solutions, serve both parties’ interests.

Communicating best practices and developing mutual trust and respect opens channels for innovation, allowing suppliers to become true strategic partners.

How to Measure SRM Performance?

To keep up with changing organizational goals and hold suppliers accountable to high standards, measuring SRM performance is critical. With a more strategic and holistic approach that enables businesses to look beyond individual supplier contributions, businesses can pinpoint where the real improvements lie.

Below are key methods to evaluate SRM performance:

- Utilize key performance indicators (KPIs) to assess supplier effectiveness.

- Implement supplier scorecards for comprehensive evaluations.

- Track cost savings achieved through effective supplier management.

- Monitor compliance with quality standards and contractual obligations.

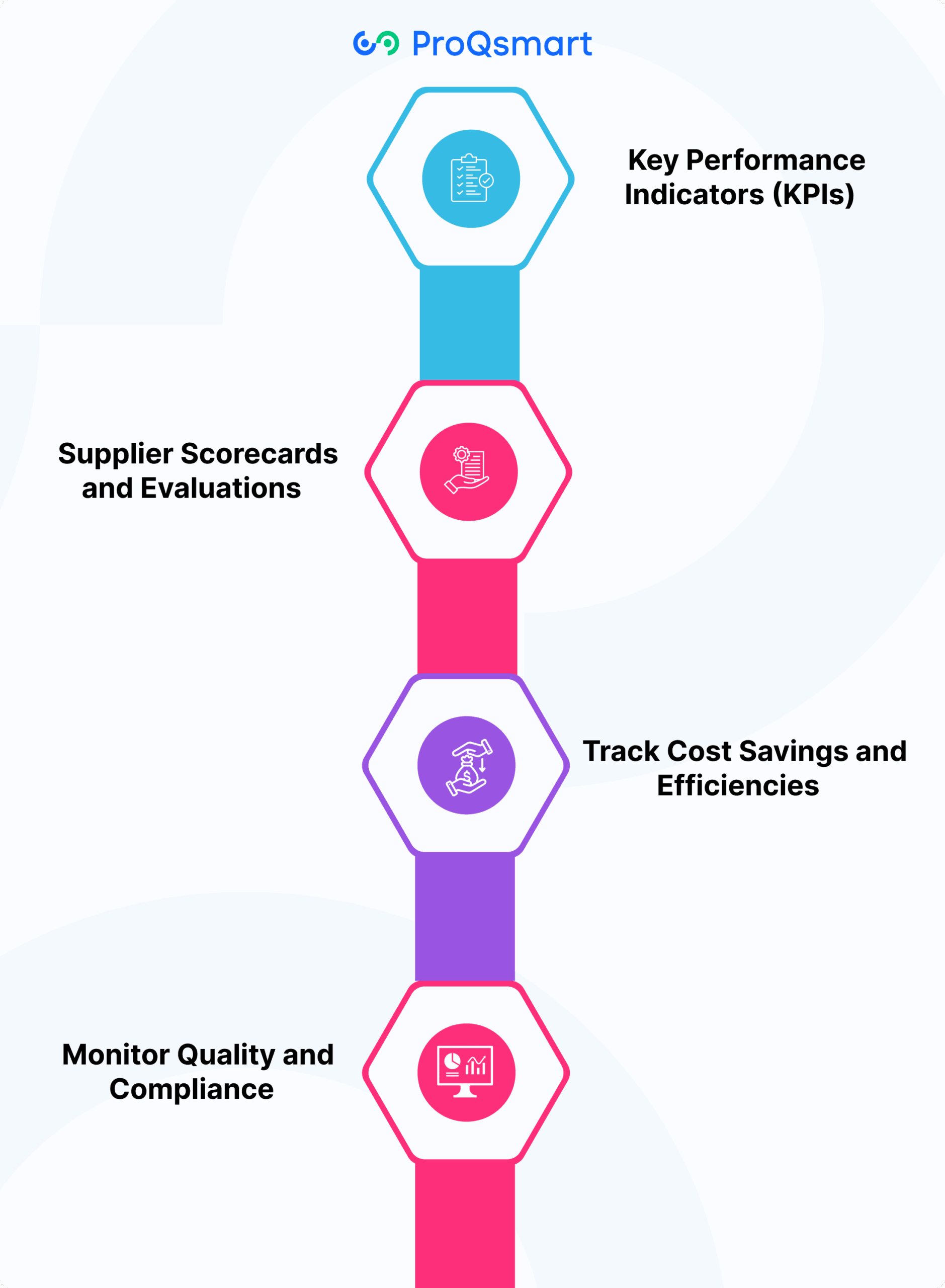

Key Performance Indicators (KPIs)

KPIs are quantifiable indicators of supplier performance. Metrics such as on-time delivery and quality rating offer immediate, actionable intelligence on supplier reliability.

For instance, monitoring performance for 80% of suppliers being on par or above performance expectations highlights strong operations. Aligning KPIs with organizational objectives helps guarantee that what suppliers are contributing aligns with larger business objectives.

Consistently revisiting and recalibrating KPIs grounded in performance data will increase their relevance and effectiveness.

Supplier Scorecards and Evaluations

Supplier scorecards (called scorecards) are tools that allow you to analyze performance in detail. These requests for proposals typically list evaluation criteria like cost, quality of work, and responsiveness.

For example, by measuring supplier responsiveness, you can ensure effective communication and problem-solving capabilities. The key to building better supplier relationships is trust, which develops over time through transparent evaluations and data-driven decisions.

Track Cost Savings and Efficiencies

Not only will tracking these cost savings help you gauge the performance of your SRM efforts, but maintaining records of financial impacts, such as savings from increased efficiency with procurement processing or automated workflow, reinforces SRM’s worth.

Platforms such as ProQsmart help with cost tracking, offering deeper insights into future strategies and allowing procurement to be focused on budgetary requirements.

Monitor Quality and Compliance

Quality monitoring acts like an early warning system. In addition, regular audits ensure that the SRM is complying with all industry standards and any contractual requirements.

Preventive actions such as automatic notifications via SRM tools stop quality problems before they start, making sure your suppliers are always delivering what you need.

Leverage Technology for Effective SRM

Leveraging technology is the most effective way to enhance SRM efforts. By leveraging these digital tools, organizations can achieve real-time visibility, drive better collaboration, and improve communication with suppliers.

This change makes the supplier management process go from a tactical need to a strong, strategic differentiator based on data.

SRM Software and Platforms

SRM software centralizes supplier information, simplifying management and improving accuracy. Tools like vendor databases, contract tracking, and spend and performance dashboards increase visibility and encourage data-driven decisions.

An intuitive, easy-to-navigate interface drives fast adoption across teams, making it second nature to integrate into daily workflows. These platforms make ongoing supplier performance monitoring easier by tracking key metrics such as on-time delivery or contract compliance.

For instance, integrating with ERP or CRM systems provides a comprehensive overview of supplier interactions, enabling proactive problem-solving and informed decision-making.

Data Analytics and Reporting

Additionally, with data analytics tools revealing trends in supplier performance, procurement teams can better identify key strengths and weaknesses with suppliers. Actionable insights derived from comprehensive supplier data improve strategic planning capabilities.

Strong reporting features aid organizational compliance and risk management initiatives. For instance, predictive advanced analytics could identify the reason behind a majority of late deliveries, enabling teams to proactively fix the inefficiency before it becomes widespread.

Automation and AI in SRM

Automation not only makes creating and assigning purchase orders faster, but invoicing is automated too. Repetitive tasks become less error-prone and more efficient.

AI-driven predictive analytics measure risks and predict future supplier performance, allowing teams to make proactive decisions. For example, leveraging technology to automate workflows increases operational efficiency, allowing teams to reallocate resources toward more strategic efforts.

ProQsmart: A Supplier Management Solution

ProQsmart supports AI applications that facilitate collaboration in real-time, monitor supplier performance, and create automated workflows.

Its transparency and compliance provide cost-efficient, budget-conscious procurement, making it the perfect solution for commercial industries such as construction.

Best Practices for SRM Implementation

Adopting a Supplier Relationship Management (SRM) strategy requires a concerted effort that should be planned in a way that best suits your organization’s goals. A successful SRM strategy is all about building long term partnerships, prioritizing collaboration, and providing ongoing value.

To optimize your SRM efforts, consider the following best practices:

- Secure executive sponsorship to drive commitment.

- Define clear roles and responsibilities for team members.

- Provide training and support for effective adoption.

- Establish a governance model for oversight and accountability.

Secure Executive Sponsorship

Gaining buy-in from senior management is critical to SRM success. With strong executive support, the program will remain in line with organizational priorities, making it easier to dedicate needed resources and cultivating engagement among stakeholders.

We found that getting leadership involved bolsters relationships with suppliers by showing that your organization is committed to working together. For example, when executives make it a point to attend supplier strategy meetings, it conveys priority and reinforces mutually beneficial objectives.

Define Clear Roles and Responsibilities

Establishing clear roles within the SRM team avoids confusion and improves accountability. A clearly organized crew with clear on-site duties makes sure everybody is working to their strengths.

This improves teamwork, reduces duplication of efforts, and smooths the process overall. With defined roles and responsibilities, SRM teams maximize awareness of supplier performance across the organization, lowering risks and creating an environment for ongoing improvement.

Establish a Governance Model

A clearly defined governance model governs supplier relationship management (SRM) efforts, holding team members accountable while ensuring alignment with organizational goals. Frequent evaluation of governance efficacy, along with strong supplier performance management practices, allows for better decision-making and long-term delivery of value.

Integrate SRM with Existing Systems

Through SRM integration with other tools such as ProQsmart, centralized supplier data enhances supply chain visibility and automates workflows. With features like real-time collaboration and supplier performance management, maintaining efficiency becomes the norm, ensuring strong supplier relationships.

SRM’s Impact on Cost and Efficiency

Supplier Relationship Management (SRM) is a holistic, strategic approach that transcends traditional supplier management. It seeks to promote new partnerships and enhance supplier collaboration, providing real impacts in both cost savings and efficiencies. By emphasizing the importance of cultivating strong supplier relationships, companies can achieve consistent supplier performance management, paving the way for sustained impact in their procurement process.

Drive Long-Term Cost Savings

To me, effective SRM is when you’re constantly driving sustained cost reductions because you’ve built long-term, mutually beneficial relationships with your suppliers.

Optimizing cost Collaboration through public-private partnerships is key to maximizing cost savings. It encourages collaborative forecasting, demand planning, and joint problem identification and resolution, leading to reduced redundancies by default.

For instance, ProQsmart’s supplier performance monitoring tools ensure consistent evaluation, empowering businesses to renegotiate contracts based on performance insights, driving savings effectively.

Improve Operational Efficiency

With SRM, operational processes are more streamlined because on-time deliveries and quality checks are frontlined. Automated workflows, like order processing and invoice management reduce mistakes and allow staff to pivot towards more strategic initiatives.

Further pillars to regular communication and close collaboration with suppliers promote understanding and transparency, working together to identify potential problems before they arise. ProQsmart increases collaborative possibilities through its real-time features.

This coordinated approach between stakeholders reduces administrative burdens that can cause considerable interruptions to daily operations. Ongoing innovation is fueled by data intelligence, allowing more efficient and predictable procurement cycles.

Optimize Inventory Management

SRM allows us to take better control of our inventory practices, encouraging just-in-time delivery to minimize surplus inventory and warehousing expenses. Collaboration with suppliers ensures accurate demand forecasting, minimizing waste and ensuring inventory aligns with production needs.

ProQsmart’s tools automate many inventory-dragging processes, helping businesses become more agile and responsive to demand shifts. These improvements reduce carrying costs and improve cash flow efficiency.

Reduce Risks and Disruptions

Proactive SRM mitigates risks like supply chain disruptions, data breaches, or regulatory non-compliance. Regular risk assessments and contingency plans ensure preparedness for unforeseen events.

ProQsmart enables businesses to monitor supplier performance and compliance, reducing vulnerabilities and ensuring smooth operations. By identifying potential risks early, we secure supply chains and maintain continuity.

Conclusion

Effective supplier relationships are the cornerstone of successful construction procurement. By fostering trust, establishing clear communication, and aligning goals with suppliers, construction companies can achieve enhanced operational efficiency and improved project outcomes. A well-structured supplier relationship management (SRM) strategy not only yields cost savings and increased efficiency but also bolsters competitive advantage.

Implementing streamlined SRM processes can be challenging, but leveraging technology can significantly enhance outcomes. Utilizing tools that track performance, manage data, and facilitate collaboration can expedite and optimize processes. Regular audits and adherence to best practices ensure that SRM strategies operate at peak efficiency and effectiveness.

Investing in SRM is a strategic decision that extends beyond supplier management; it involves cultivating relationships that drive sustainable results for both projects and organizations. To maximize the potential of your supplier relationships, consider integrating advanced SRM solutions. ProQsmart offers a comprehensive platform designed to enhance collaboration, streamline workflows, and drive business success in construction procurement. Schedule a demo with ProQsmart today!