Indirect materials play a crucial role in the daily operations of businesses, often serving as the unsung backbone that supports seamless production and service delivery. Items such as office supplies, repair tools, and safety equipment are essential for maintaining efficient day-to-day operations.

While indirect materials may not be directly involved in the production of finished goods, they are vital for ensuring that industries operate smoothly and effectively. Effective management of these materials contributes to streamlined workflows, improved cost control, and minimized disruptions across organizations.

Understanding the significance of indirect materials is essential for businesses, as they can account for a substantial portion—up to 90%—of a company’s total materials costs. By adopting strategic procurement practices, organizations can enhance their supply chain resilience, advance sustainability initiatives, and achieve cost reductions.

What Are Indirect Materials?

Indirect materials are essential to ensuring production processes run smoothly and efficiently. Often categorized under indirect material management, these costs are not immediately associated with the production of tangible goods. In accounting, such costs are referred to as indirect materials, which can either be part of manufacturing overhead or expensed immediately as incurred, depending on the company’s accounting practices.

Consumables including lubricants, disposable gloves, and cleaning supplies are critical for the efficient use of resources. They support keeping production running at maximum efficiency and help maintain smooth operations. While they don’t end up in the final product, their role in the overall manufacturing process is indispensable.

The value of indirect materials goes deeper than operational efficiency. They are critical for protecting worker health. Personal protective equipment (PPE), such as helmets, gloves and goggles, are all considered indirect materials. These vital tools protect workers from hazards in dangerous workplaces.

The challenge lies in their traceability: indirect materials cannot be linked to specific jobs or products, complicating cost allocation. As a solution, many companies are adopting centralized inventory management software and indirect material optimization technologies to track their usage and minimize wastefulness.

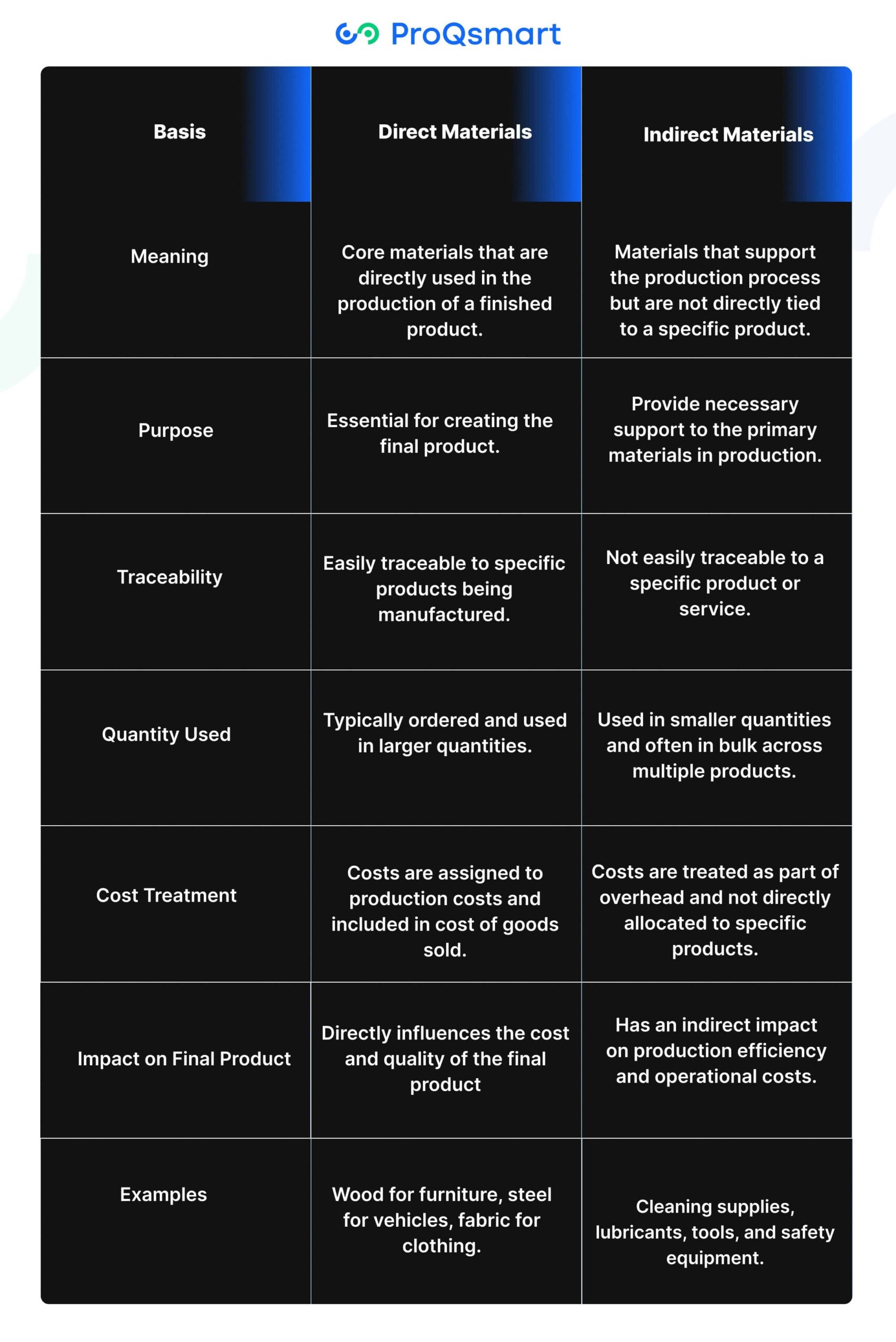

Differences Between Direct and Indirect Materials

Basis | Direct Materials | Indirect Materials |

Meaning | Core materials that are directly used in the production of a finished product. | Materials that support the production process but are not directly tied to a specific product. |

Purpose | Essential for creating the final product. | Provide necessary support to the primary materials in production. |

Traceability | Easily traceable to specific products being manufactured. | Not easily traceable to a specific product or service. |

Quantity Used | Typically ordered and used in larger quantities. | Used in smaller quantities and often in bulk across multiple products. |

Cost Treatment | Costs are assigned to production costs and included in cost of goods sold. | Costs are treated as part of overhead and not directly allocated to specific products. |

Impact on Final Product | Directly influences the cost and quality of the final product. | Has an indirect impact on production efficiency and operational costs. |

Examples | Wood for furniture, steel for vehicles, fabric for clothing. | Cleaning supplies, lubricants, tools, and safety equipment. |

Role of Indirect Materials in Manufacturing

Supporting Production Processes

Their role in avoiding unexpected halts to production runs is enormous. Now picture a manufacturing nightmare where a critical machine goes down because no one could get her maintenance supplies.

With the right indirect materials readily available, you can avoid workflow disruptions by fixing safety hazards and equipment damage before they become a problem. Appropriate management systems, like inventory software, actively and automatically track materials in real time.

This minimizes downtime and increases productivity by guaranteeing that necessary items are quickly accessible.

Impact on Operational Efficiency

Ineffective use of indirect materials has a direct and significant effect on operational performance. With automated tracking systems, manufacturers are able to better understand trends in usage, optimize trends, and reduce waste.

Centralized systems simplify the ordering process. They make sure consumables are ordered in the correct amounts, decreasing wasteful purchases and freeing up spending.

Waste reduction and circularity can be achieved by ensuring the use of indirect materials supports production goals. This optimization moves resources where they are needed most, minimizing both time and money spent, resulting in an efficient operation from top to bottom.

Contribution to Cost Management

Effective management of indirect materials can produce significant cost savings, particularly in the area of overhead costs. As an example, 70% of these materials go toward maintenance and repair, so realizing their full potential through the most efficient allocation is essential.

Centralized management provides a better way to track expenses, identify inefficiencies and implement cost-saving strategies to ensure every dollar is maximized.

Importance of Indirect Materials in Procurement

Indirect materials are crucial for establishing innovative procurement strategies. Yet, they are frequently the backbone of an organization’s daily operations.

Even though they don’t directly produce their end product, they are key to ensuring the business operates effectively and efficiently. Their effective management can have a profound as well as positive impact on procurement performance overall by making processes more efficient and lowering operating costs.

For most organizations, indirect spend accounts for 15% to 30% of total revenue. Organizations that take charge of this procurement area are likely to realize hundreds of thousands in cost savings and increased efficiency.

Enhancing Procurement Strategies

First and foremost, get a holistic picture of what your organization needs and what its priorities are. Understanding this paradigm is key to smartly including indirect materials in your procurement strategy.

Creating a centralized procurement system for indirect purchases allows for central control and visibility. Aligning indirect materials management with wider business priorities, like sustainability and cost reduction, delivers even more measurable value.

Strong supplier relationships are key to success here. Working with trusted vendors to handle IT needs or janitorial services improves the level of service. Not only does this improve cost predictability, it helps make your procurement strategy more adaptable and better aligned with your organization’s objectives.

Reducing Operational Risks

As with most risks to operations, effective management of indirect materials can be a strong line of defense against risks manifesting. Regardless of the spend category, procurement practices matter.

Poor practices like reliance on unvetted suppliers can result in major disruptions or invisible costs. Risks such as variability in the quality of product or delays in supply reveal the need for extensive supplier evaluations with an emphasis on building long-term agreements.

Creating a supplier base populated by diverse and reliable vendors decreases dependency and increases the chance of uninterrupted operations even amid market fluctuations.

Improving Supply Chain Management

Indirect materials play a key role in enhancing supply chain efficiency by improving inventory management and replenishment cycles.

In other words, an effective indirect materials procurement system for packaging materials or safety gear avoids building up an excess inventory or scrambling for supplies at the last minute.

Use technology like ProQsmart to track and forecast to make indirect materials part of your overall supply chain strategy. Failure to do so can undermine smooth operations and good cost management.

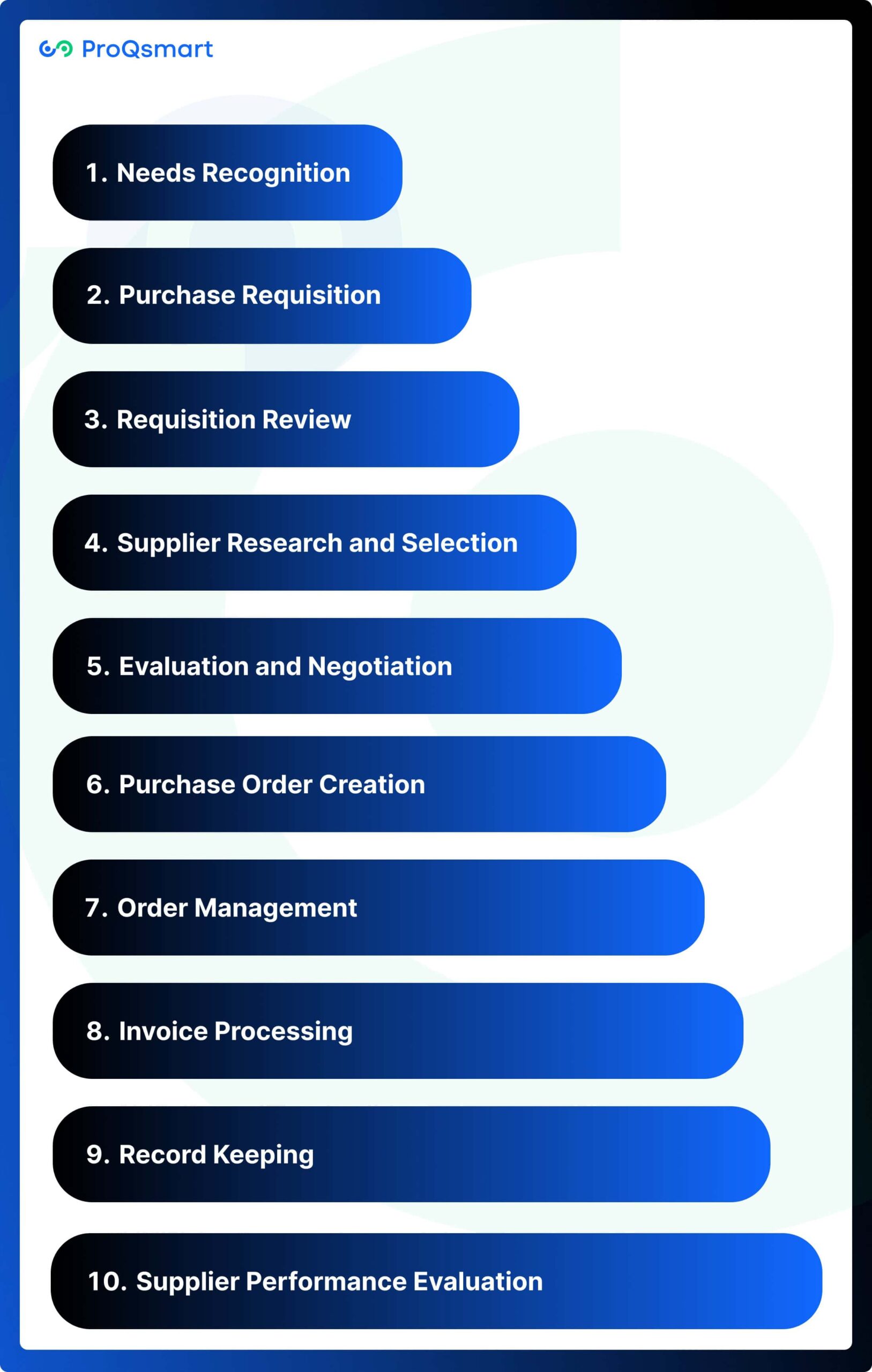

Procurement Processes for Indirect Materials

The procurement process for indirect materials management in manufacturing involves several critical steps to ensure that essential supplies, including raw materials and indirect material optimization technologies, are acquired efficiently and effectively.

1. Needs Recognition

Identify and assess the specific indirect materials required for manufacturing operations, such as maintenance tools, safety equipment, and office supplies. This step involves collaboration with various departments to understand their needs.

2. Purchase Requisition

Create a purchase requisition (PR), which is an internal document that outlines the requested materials, quantities, and justifications. This document is submitted for approval to ensure that the procurement team can proceed with sourcing.

3. Requisition Review

The procurement team reviews the purchase requisition to verify the necessity of the requested items and check budget availability. Approved requisitions move forward in the process, while rejected requests are returned with feedback.

4. Supplier Research and Selection

Conduct research to identify potential suppliers for the indirect materials needed. This may involve sending out requests for quotations (RFQs) to multiple suppliers to gather pricing and terms.

5. Evaluation and Negotiation

Evaluate supplier responses based on criteria such as cost, quality, delivery timelines, and reliability. Engage in negotiations with selected suppliers to finalize pricing and contract terms.

6. Purchase Order Creation

Once a supplier is chosen, create a purchase order (PO) that formalizes the agreement. The PO should include details such as item descriptions, quantities, prices, and delivery schedules.

7. Order Management

Monitor the order status to ensure timely delivery of indirect materials. Upon receipt, inspect the items to confirm they meet quality standards and match the specifications outlined in the PO.

8. Invoice Processing

Review supplier invoices against the purchase order and received goods to ensure accuracy through a three-way matching process (PO, goods receipt note, and invoice). Approve invoices for payment once discrepancies are resolved.

9. Record Keeping

Maintain comprehensive records of all procurement activities related to indirect materials, including purchase requisitions, orders, invoices, and supplier evaluations. This documentation supports auditing and compliance efforts.

10. Supplier Performance Evaluation

Regularly assess supplier performance based on delivery reliability, quality of materials supplied, and overall service levels. Use this information to inform future procurement decisions and improve supplier relationships.

Challenges in Managing Indirect Materials

Lack of Visibility in Procurement

One significant challenge in managing indirect materials is the lack of visibility in procurement processes. Indirect materials, such as maintenance supplies and personal protective equipment (PPE), are essential for maintaining smooth operations but often go unnoticed. Consequently, this lack of oversight can lead to inefficiencies, including overstocking or understocking, which disrupt workflows and inflate costs. For instance, a manufacturing plant may find itself with excessive cleaning supplies due to poor materials management processes, tying up capital unnecessarily, or may run out of critical spare parts, resulting in costly downtime.

Inefficient Cost Tracking

Another challenge is the ineffective tracking of indirect materials costs, which can account for a substantial portion of overall budgets. Moreover, maverick spending—purchases made outside formal procurement channels—exacerbates this issue, leading to overspending and misallocation of resources. For example, different departments might procure the same raw materials multiple times, resulting in unnecessary duplications.

Supplier Dependence and Risks

Furthermore, over-reliance on specific suppliers for indirect materials presents significant risks, including supply disruptions and price fluctuations. For example, a manufacturing facility that depends exclusively on a single supplier for maintenance tools or safety equipment may experience operational delays if that supplier faces production issues or logistical challenges, affecting the overall manufacturing process and creating vulnerabilities that adversely impact production efficiency and continuity.

Best Practices to Overcome Challenges & Managing Indirect Materials

1. Utilize Technology for Procurement

E-Procurement platforms and ERP systems such as ProQsmart, expedite processing and tracking orders automatically, minimizing human errors and optimizing employee time.

For instance, adopting procurement automation software helps companies manage incoming purchase orders more quickly and accurately. By integrating these systems with their current operations, organizations optimize workflows including easy communication between procurement, inventory, and finance teams.

Adopting smart solutions like ProQsmart can help you get even more out of your procurement efficiency. ProQsmart leverages AI to enable data-driven decision-making, automate workflows, and offer real-time tracking and visibility. Its supplier relationship management and compliance management features help businesses foster positive supplier relationships and stay compliant with regulations.

2. Implement Cost Control Measures

Cost control is essential, especially since indirect materials can account for a significant portion of annual spending. Establishing key performance indicators (KPIs) such as cost variance and procurement cycle time is crucial for effectively tracking expenditure trends.

Budgeting serves as a vital framework for managing these costs, providing a blueprint for financial oversight. Strategies like vendor-managed inventory (VMI) agreements with reliable suppliers can help maintain lower inventory levels while enhancing responsiveness to shifts in demand.

Moreover, utilizing centralized platforms for managing maintenance, repair, and operations (MRO) can lead to improved harmonization of materials data, facilitating better decision-making and operational efficiency in managing indirect materials.

3. Optimize Supplier Relationships

Underlying all successful procurement efforts are strong supplier relationships. Long-term relationships with proven suppliers guarantee quality and on-time deliveries.

Collaborative practices such as open communication, joint planning, and feedback loops improve trust and performance. When suppliers manage vendor-managed inventory (VMI), it allows businesses to focus on bigger strategic goals, creating greater efficiency overall.

4. Conduct Regular Inventory Audits

Regular inventory audits are essential for identifying discrepancies and ensuring accurate stock levels. By systematically reviewing inventory, organizations can refocus their efforts to optimize stock management. Utilizing techniques that promote lean inventory helps prevent both overstocking and stockouts.

Additionally, audits enhance compliance and accountability within the procurement process, helping to protect its integrity. By implementing regular audits, organizations can improve operational efficiency and make more informed decisions regarding their indirect materials.

5. Standardize Procurement Processes

Standardized procurement processes enhance clarity and create consistency, limiting inefficiencies in the entire supply chain. Written policies detailing vendor selection, ordering, and payment procedures support effective resource management and streamline materials management tasks.

Conclusion

Indirect materials play a crucial role in ensuring smooth and efficient operations within an organization. Their effective management is essential for maintaining the quality and consistency of production, achieving cost savings, and preventing waste. Adopting robust procurement practices and engaging directly with suppliers can significantly enhance this often-overlooked area.

Implementing technology thoughtfully can transform the management of indirect materials into a strategic advantage. By fostering collaboration with suppliers, businesses can develop a shared understanding that leads to solutions that save time, reduce risks, and improve overall performance.

To optimize your approach to indirect materials, it is important to evaluate your current practices. Small adjustments can lead to significant improvements, ultimately contributing to a more resilient operational infrastructure. Effective management today lays the groundwork for stronger growth in the future.

For organizations looking to enhance their procurement processes, ProQsmart offers valuable solutions for streamlining indirect materials management. Book a demo today to discover how ProQsmart can support your organization’s success.