Supplier performance management is the process of evaluating and improving supplier contributions to achieve organizational goals. By assessing metrics like delivery timelines, quality of goods, cost-effectiveness, and adherence to contracts, businesses gain insights into supplier reliability and overall value.

Effective management ensures stronger supplier relationships, minimizes risks, and supports consistent supply chain operations. Moreover, leveraging supplier performance data helps organizations identify areas for improvement and maintain compliance with industry standards.

Focusing on measurable outcomes enhances operational efficiency and fosters trust and accountability between partners. Understanding these dynamics is crucial for professionals aiming to optimize procurement strategies.

The following sections will explore practical approaches and tools to strengthen supplier performance management.

Why Supplier Performance Matters

Supplier performance management helps ensure procurement’s continued relevance in today’s turbulent market and procurement landscape, enabling continued operational stability and competitive advantage. With nearly 80% of companies depending on third-party suppliers, the ability to monitor and enhance supplier performance directly influences cost efficiency, innovation, and long-term success.

Smart management means that businesses get the best possible goods and services, which is important for keeping operations running smoothly, and customers happy and well served.

Reduce Supply Chain Risks

The ripple effects of poor supplier performance can result in raw material shortages, delayed service or other disruptions that cause production to stop. To take one example, manufacturing facilities can quickly encounter critical shutdowns if raw materials are not delivered on-time and with high quality.

By consistently keeping an eye on supplier performance, companies can mitigate risks before they become serious issues. They keep an impressive database of supplier performance data. Proactive management, such as using clearly defined performance metrics, ensures smooth operations while retaining flexibility to adapt to unforeseen changes.

Open lines of communication promote transparency and can help nip problems in the bud before they result in damaging consequences.

Improve Cost Efficiency

Individual high-performing suppliers have the capacity to reduce procurement costs by large margins. By tracking key performance metrics, such as defect rates and delivery times, companies can identify their best suppliers.

Together with communities, it allows them to find innovative and less expensive solutions. In addition to saving money, negotiating terms with these suppliers increases profit margins by maximizing revenue.

Digital tools like ProQsmart, for instance, help make fast, accurate supplier evaluations a breeze, keeping procurement on track for budgetary objectives.

Foster Innovation

When done as a part of collaborative supplier performance management, suppliers will be more willing to share their best innovative ideas and technologies. With shared knowledge, continuous performance improvement of products and further innovations across the supply chain can be achieved.

Creating channels for ongoing supplier performance feedback fortifies these vital partnerships with new opportunities for shared success.

Strengthen Supplier Relationships

Developing trust with key suppliers through effective supplier performance management and open communication will enhance your supplier relationships. Long-term partnerships foster consistent service levels, improved quality products, and greater reliability.

How to Manage Supplier Performance?

Proactive supplier performance management (SPM) is the only way to ensure your suppliers are meeting your organization’s needs and standards. First, it informs value-centric delivery and operational agility. By emphasizing measurable results and creating a culture of collaboration, you can maximize efficiency and improve supplier partnerships.

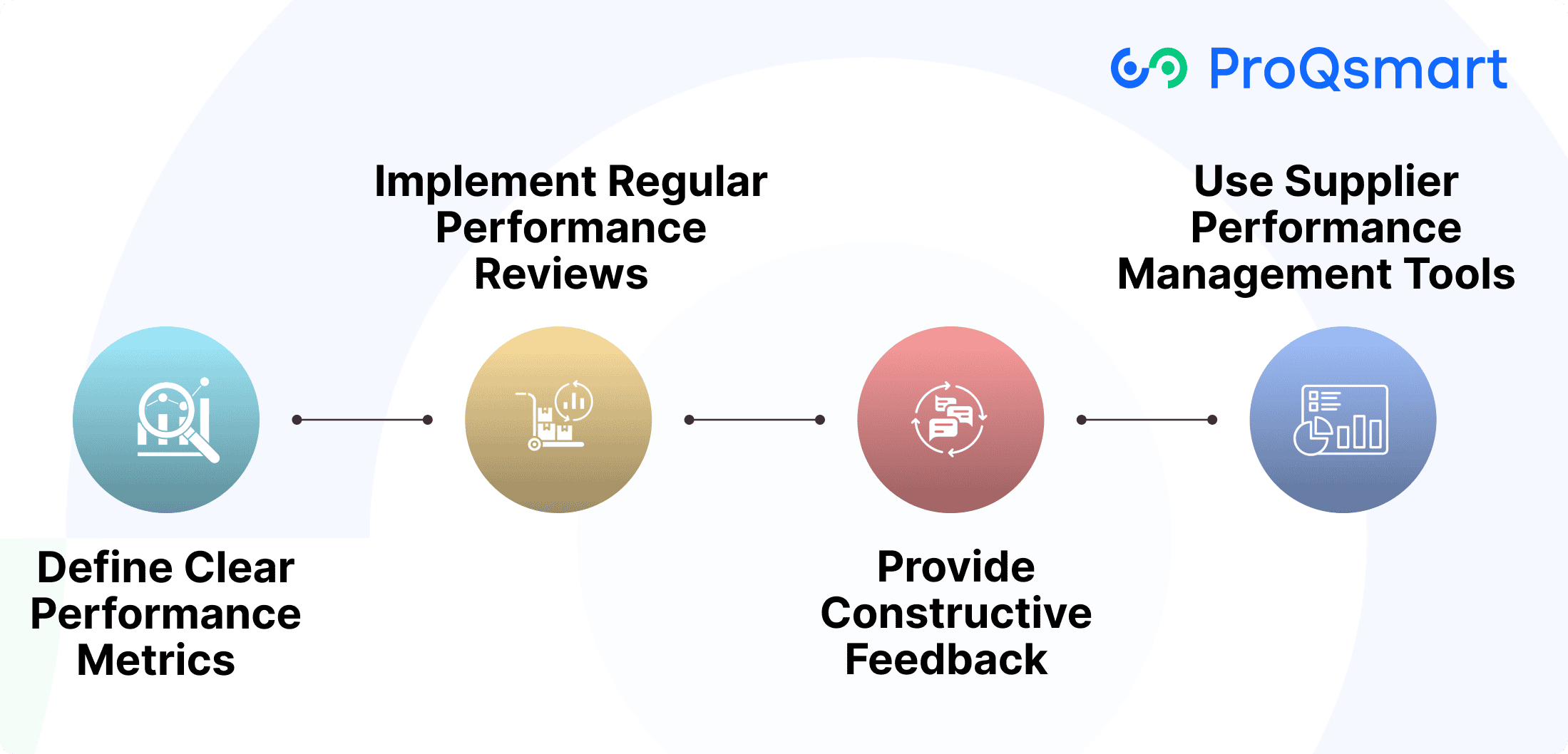

Below are actionable steps to manage supplier performance effectively:

1. Define Clear Performance Metrics

Establishing specific, measurable, achievable, relevant, and time-bound (SMART) goals is critical. Metrics such as on-time delivery, quality of goods, lead times, and cost adherence should align closely with your business objectives.

For instance, monitoring lead times can lead to better inventory level decisions, lowering carrying costs related to surplus goods and avoiding costly stockouts. Revisiting and recalibrating these metrics on a regular basis keeps them focused on what’s important to a changing business landscape.

2. Implement Regular Performance Reviews

Consistent evaluations, whether monthly, quarterly, or annually, provide valuable insights into supplier performance. Documenting these outcomes will help create accountability to do better and have more candid conversations about how to improve.

Involving stakeholders in these periodic reviews helps you cultivate a more holistic view of your suppliers’ contributions and hurdles.

3. Provide Constructive Feedback

Delivering feedback with specificity rather than generalizations encourages suppliers to address exact issues and improve. Instead of saying “delivery is poor,” point to specific deadlines missed and recommend a plan that details concrete steps to improve.

This mission-centric approach encourages innovation and cooperative spirit.

4. Use Supplier Performance Management Tools

Technology like ProQsmart simplifies monitoring by automating performance tracking, reviewing compliance, and strengthening supplier collaboration through real-time data.

Its powerful, AI-driven insights help procurement drive progress towards budgetary objectives and regulatory requirements.

Key Performance Indicators (KPIs) for Suppliers

Key Performance Indicators (KPIs) serve as measurable benchmarks to evaluate supplier performance, ensuring alignment with organizational goals. By analyzing these metrics, businesses can strengthen supplier relationships, enhance efficiency, and mitigate risks.

Below is a table summarizing the primary KPI categories:

|

KPI Category |

Definition |

Metric Example |

|---|---|---|

|

Delivery Time & Reliability |

Measures timeliness of deliveries |

On-time delivery rate (%) |

|

Product/Service Quality |

Assesses quality standards |

Defect rate (%) |

|

Cost Competitiveness |

Evaluates cost-effectiveness |

Cost variance (%) |

|

Responsiveness & Communication |

Gauges responsiveness and problem resolution |

Response time (hours/days) |

|

Innovation & Improvement |

Tracks supplier contributions to innovation |

Number of co-developed projects |

|

Compliance & Ethics |

Ensures adherence to ethical and regulatory norms |

Audit compliance rate (%) |

|

Financial Stability |

Analyzes financial health |

Credit score, financial ratios |

|

Sustainability Practices |

Monitors environmental and social responsibility |

Emissions reduction (%), waste management |

Delivery Time and Reliability

Reliability in delivery is key to keeping the trains running on time. Direct measures like on-time delivery rate (percentage of orders delivered on time) can help you paint a picture of your suppliers’ reliability.

Advanced, real-time data analytics built into solutions such as ProQsmart provide immediate, on-demand insight into delivery patterns and trends. For example, automated alerts can flag delays, making it possible to take corrective action quickly.

Product or Service Quality

Quality is crucial. Not surprisingly, quality is essential to customer satisfaction and loyalty. Defect rate, the measure of products or services that fail to meet quality specifications as a percentage, promotes consumer confidence and quality assurance.

For instance, a defect rate of less than 2% from a supplier indicates very low defectiveness. Tools such as ProQsmart use in-depth reporting to discover and then financially benefit high-performing suppliers.

Cost Competitiveness

Establishing cost-effectiveness is a key element of procurement driven by budgets. By monitoring metrics like cost variance, organizations can quickly detect when they’re overspending and take steps to stay on budget.

ProQsmart also leads the industry in creating cost savings opportunities with automated workflows and precise sourcing data.

Responsiveness and Communication

The key to strong collaboration is always good communication. Response time metrics—including average hours to respond to inquiries—showcase supplier flexibility.

With ProQsmart’s real-time collaboration features, it goes a step further, making sure any issues are addressed or resolved in real time.

Innovation and Improvement

Suppliers who think outside the box provide tremendous value. Tracking other projects they’ve co-developed, for example, shows their desire to deliver more than what’s on the typical contract.

Supporting and cultivating these types of partnerships can provide a significant competitive advantage.

Compliance and Ethics

These ethical practices and regulatory compliance go hand in hand and are non-negotiable. Performance metrics such as audit compliance rates show alignment with applicable standards and industry best practices, minimizing the risk of operational failures.

With ProQsmart’s advanced compliance monitoring, businesses can be rest assured that it is a vital instrument.

Financial Stability

A supplier’s financial health is essential to fostering long-term partnerships. Metrics like credit scores or relevant financial ratios provide clear parameters for determining their trustworthiness.

This further aids in reducing risk from sudden supplier loss.

Sustainability Practices

Mitigation of social and environmental harms is an increasingly pressing interest. Measures including emissions reduction rates and waste management efforts show a supplier’s commitment to environmental and social responsibility.

Suppliers improving business alignment with these values can help strengthen social and sustainable procurement strategies.

Leverage Technology for SPM

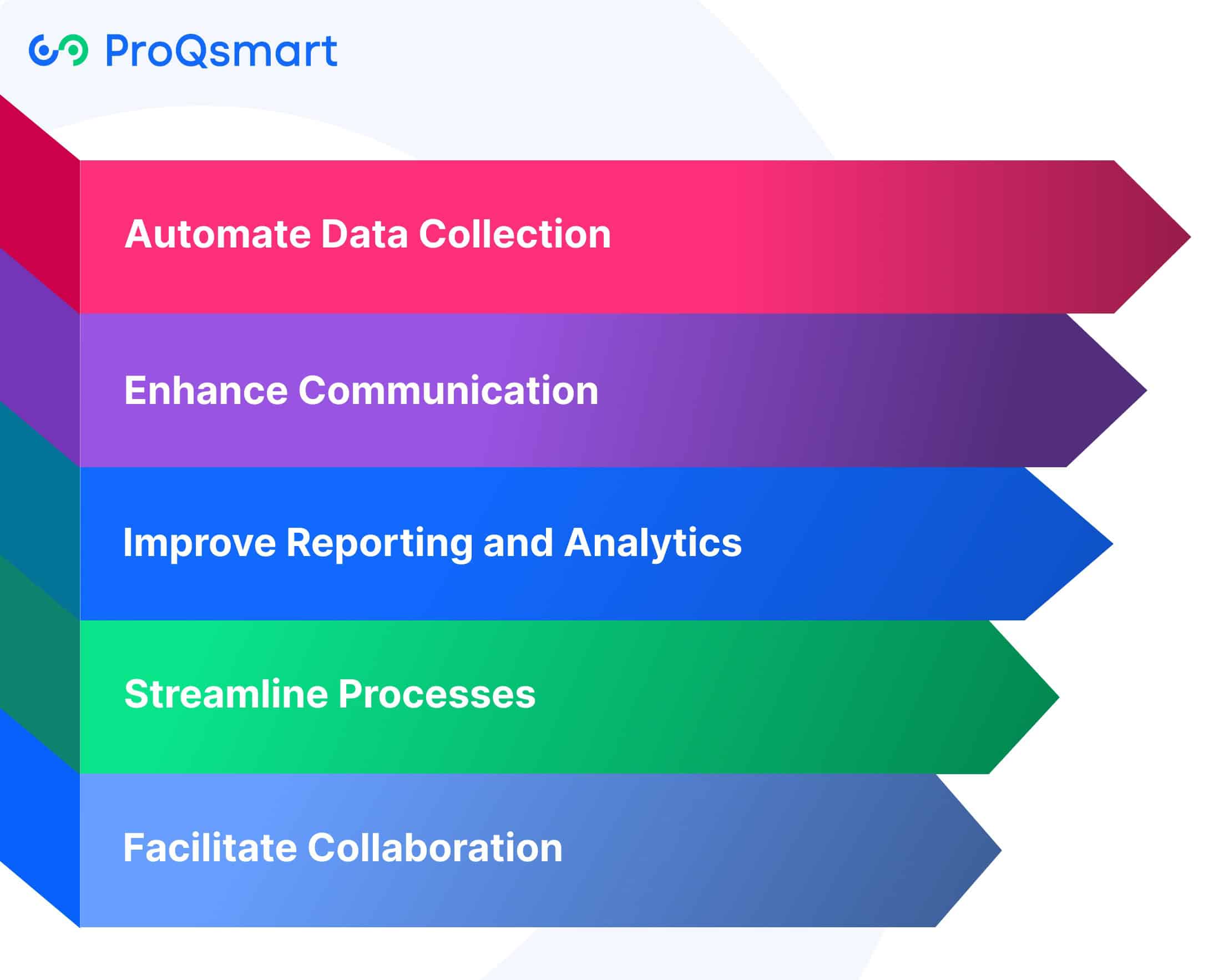

Integrating advanced technology into supplier performance management (SPM) can transform how businesses oversee their supplier relationships, improve efficiency, and make data-driven decisions. Tools such as cloud-based platforms, data analytics, and automation software offer real-life solutions to daily procurement pain points.

ProQsmart is a collaborative procurement platform that uses AI to improve MBE/DBE decision-making and to automate workflow. Beyond meeting regulatory requirements, it fosters collaboration and transparency across the organization.

Automate Data Collection

Automated data collection removes the step of entering that information manually, reducing data entry errors by as much as 90%, and saving thousands of hours. This gives organizations the confidence that all supplier data —no matter the source, internal systems, or third-party platforms— is easily integrated and accessible.

Solutions like Cin7 Connected Inventory Software simplify managing extensive supplier data, addressing inefficiencies of outdated systems like Excel. Automation frees organizations up to do the quality, strategic work that makes them great—not trapped under the weight of administrative minutiae.

Enhance Communication

Today’s best tools for communication that can be easily integrated within platforms like ProQsmart create ongoing, real-time collaboration with suppliers. These capabilities deepen supplier relationships by providing clarity of expectations and expedited resolution of any issues.

ProQsmart’s e-tenders, for instance, make the entire bidding process and document management seamless, promoting transparency and trust.

Improve Reporting and Analytics

Data analytics tools can monitor key metrics across the entire supply base and provide real-time visibility into supplier scorecards. With effective supplier performance management, organizations can detect trends and risks early, enabling evidence-based decisions to prevent issues and enhance supplier performance monitoring.

Streamline Processes

Automated workflows save time by promoting efficiency and consistency across procurement processes. ProQsmart’s budget-driven procurement and subcontractor management contribute to successful supplier performance management, helping keep everyone aligned with organizational goals while minimizing costly manual errors.

Facilitate Collaboration

Collaborative features built into platforms such as ProQsmart foster innovation and collaboration among businesses and suppliers, enhancing effective supplier performance management. This builds alignment of shared objectives, providing a platform for successful supplier performance management.

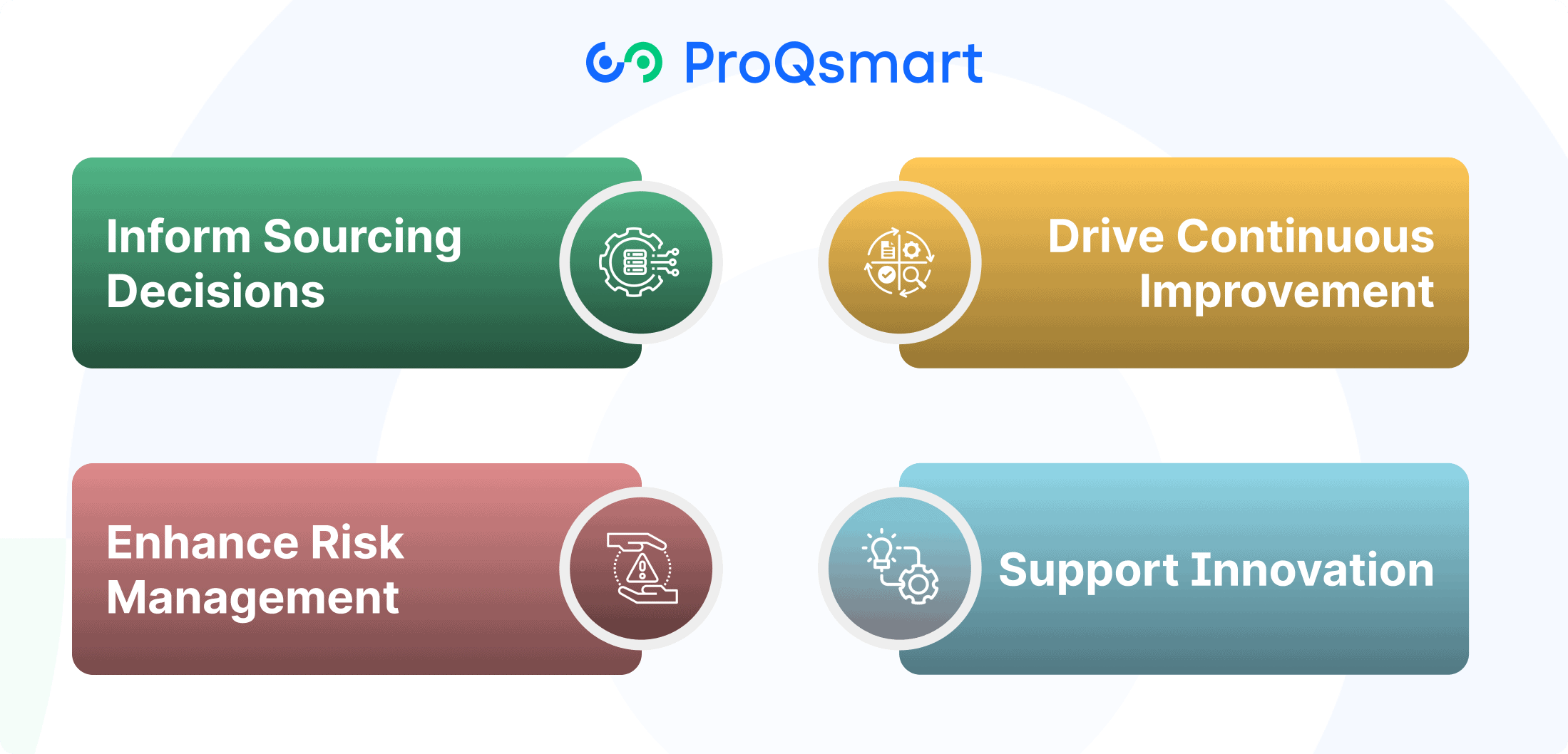

SPM’s Role in Strategic Procurement

Supplier Performance Management (SPM) is a foundational element of strategic procurement. It’s all about weighing supplier’s ability to deliver and making sure they perform according to organization’s objectives. While Supplier Relationship Management (SRM) focuses on developing relationships with key suppliers, SPM is far more data-driven, measuring and improving supplier performance and value-add.

The result is streamlined supply chain processes, helping organizations stay one step ahead in an increasingly competitive landscape.

Inform Sourcing Decisions

SPM plays a key role in informing sourcing strategies. Through accurate, clear data on supplier performance, organizations can gain confidence that they are working with the best-suited suppliers. For instance, if a supplier has a defect rate greater than 15%, this should indicate further concerns that need to be addressed right away.

ProQsmart’s AI-driven platform makes this process easy by consolidating and analyzing key supplier information, helping ensure suppliers meet strategic procurement standards. This systematic, evidence-based method minimizes risks and improves procurement results.

Drive Continuous Improvement

By tracking results through consistent reviews, be it on a monthly basis or quarterly, SPM encourages tangible progress. With well-defined goals and ongoing dialogue, organizations and suppliers work together to solve problems and meet objectives.

Automated performance tracking, like ProQsmart provides, takes the grunt work out of evaluations, allowing teams to double down on what drives real progress without all the red tape.

Enhance Risk Management

A strong SPM framework proactively reduces risks by recognizing where future disruptions may occur well in advance. Centralized repositories for all supplier data, paired with automated workflows, offer the transparency and accountability procurement teams increasingly need.

By working in advance of the procurement, conflicts are prevented from coming to a head, which protects the overall flow of the supply chain.

Support Innovation

SPM helps drive innovation through collaborative supplier relationships. Establishing clear performance expectations helps set the stage for suppliers to bring forth innovative solutions that deliver value.

With ProQsmart as your collaboration hub, you’ll have the ability to unlock supplier ingenuity, drive innovation, and accomplish procurement goals—all in real time.

Conclusion

Supplier performance management is essential for maintaining an efficient and effective procurement process. It strengthens supplier relationships, drives operational excellence, and delivers impactful results. By leveraging accurate KPI tracking and advanced technology, you gain access to dynamic, real-time data that enables quick pivots and better outcomes. A stronger emphasis on supplier performance helps mitigate risks, reduce costs, and create sustainable value for your organization.

Every incremental improvement in how you manage suppliers fortifies your supply chain and positions your business for long-term success. It’s no longer just about managing suppliers—it’s about forging productive partnerships that foster collaboration, innovation, and growth.

Ready to transform your supplier performance management? ProQsmart can help you achieve smarter procurement operations with cutting-edge tools and real-time insights. Book a demo today!