Sourcing optimization is a strategic approach to procurement that aims to deliver maximum value to organizations by cutting costs and fostering stronger relationships with suppliers. This involves analyzing spending trends to identify the best suppliers and leveraging data-driven insights to inform sourcing decisions. By automating processes and utilizing modern procurement tools, businesses can develop more effective and environmentally friendly sourcing practices.

Beyond cost savings, sourcing optimization enables companies to remain competitive in a rapidly changing market. It also helps organizations meet their compliance and sustainability goals, ensuring that procurement practices align with broader business objectives. In this article, we will explore actionable strategies and best practices for optimizing sourcing processes, setting your company up for long-term success and sustainability in the manufacturing sector.

How Does Sourcing Optimization Work in Manufacturing?

Sourcing optimization software enhances the way organizations select suppliers and create sourcing plans. This intentional sourcing process increases efficiency and better positions the organization to achieve its goals. It emphasizes the importance of cost analysis, supplier performance evaluation, and risk management in achieving successful procurement decisions.

- Meanwhile, sourcing optimization is more important than ever for businesses. It aids them in optimizing cost, quality, and supplier reliability while allowing them to manage the intricacies of today’s challenging supply chains.

- Although it’s critical, issues like supplier compliance, price increases, and quality variations often arise. Unreliable suppliers could speed up or delay production schedules. Cost volatility can put a huge strain on budgets, and unreliable quality can impact customer satisfaction. Overcoming these challenges will take a concerted approach backed by research-informed expertise and innovative partnership.

- Leveraging advanced data analytics is key to improving sourcing decisions. By measuring supplier performance against metrics such as on-time delivery rates, defect rates, and cost variance, organizations are armed with data to make decisions. Solutions like ProQsmart are a great example of this, leveraging AI to simplify procurement processes, automate compliance, and proactively track supplier performance.

- Strong outreach and engagement strategies are just as important. Regular check-ins, structured feedback loops, and transparent exchanges build deeper supplier relationships, minimizing surprises and misunderstandings while bringing both parties’ goals and missions into closer alignment.

- ProQsmart provides the most powerful real-time collaboration tools so you can work together easily and effortlessly. Its supplier relationship management features encourage transparency, fueling collective growth and establishing trust.

- Creating solid contingency plans for supply chain disruptions adds another layer of protection. Whether faced with natural disasters, geopolitical events, or logistical bottlenecks, having well-established options reduces the risk of future disruptions.

Future Trends in Sourcing Optimization

Sourcing optimization is a field that’s changing faster than ever, pushed by new technologies, increased consumer demand, and a focus on sustainability. These shifts are reshaping procurement strategies, creating opportunities for organizations to enhance efficiency, reduce costs, and build lasting supplier relationships.

Here, we take a closer look at some of the most important trends impacting the future of sourcing optimization, and what they mean for procurement professionals.

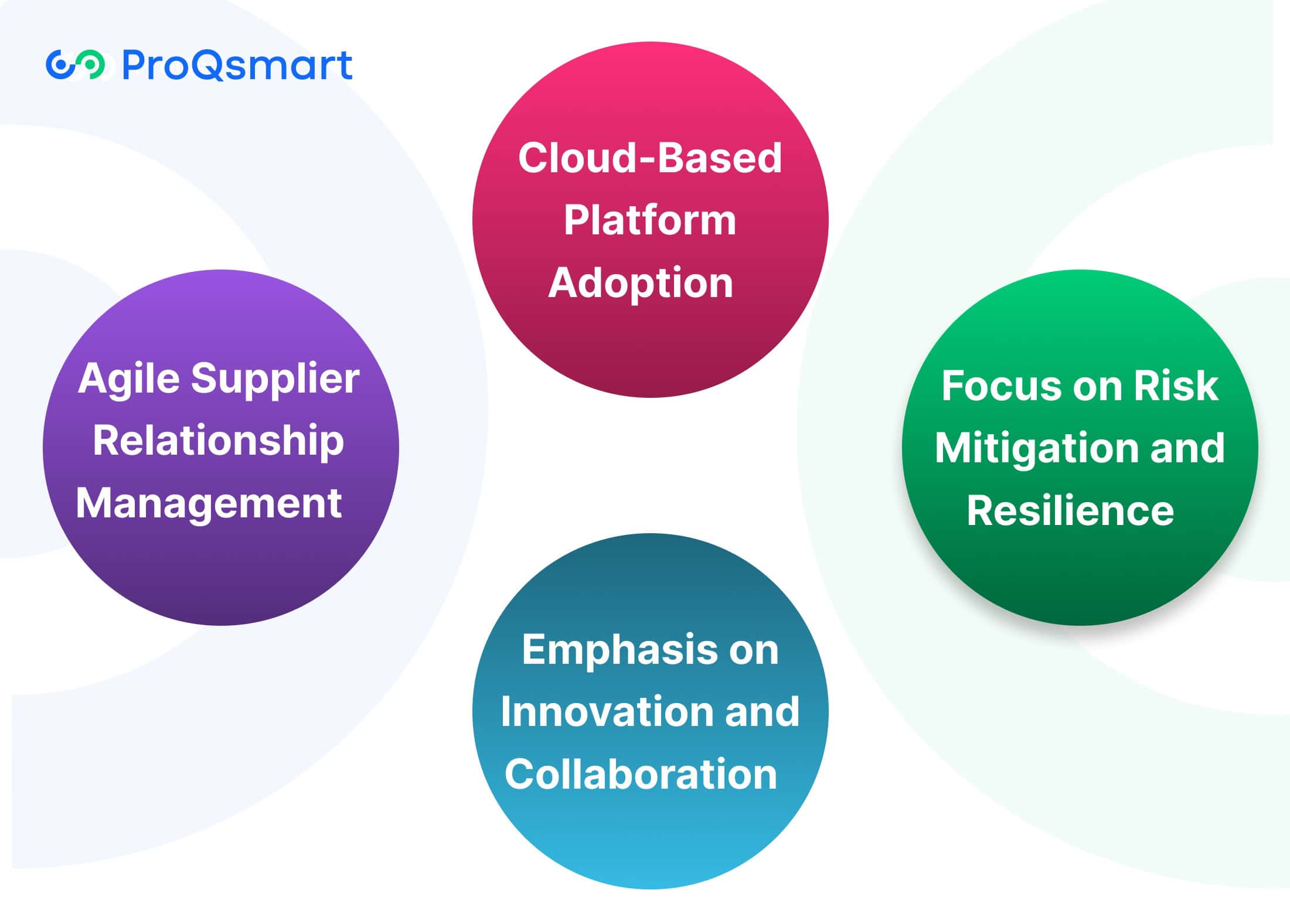

Cloud-Based Platform Adoption

These cloud-based platforms are changing the game by introducing powerful, centralized, and accessible tools for procurement and sourcing management. Innovative platforms such as ProQsmart have developed incredible capabilities, from e-tendering to supplier performance monitoring.

These features dramatically simplify the workflow process and lead to better data-driven decisions. These tools automate the pre-qualification process, manage subcontractors, and ensure compliance with evolving sourcing data, all while aligning procurement with real-time budgets.

Automation, Data and AI With ProQsmart AI-driven solutions like ProQsmart’s, businesses can gain unmatched transparency and a 10% – 40% cost savings. With increased enterprise adoption of digital platforms, the overall procurement landscape will experience greater collaboration and efficiency, rendering cloud-based solutions inescapable.

Focus on Risk Mitigation and Resilience

The increasingly unpredictable nature of supply chains requires organizations to place a greater emphasis on risk mitigation and resilience. Advanced analytics and AI-powered tools are helping organizations identify disruptions before they occur.

They play an important role in evaluating supplier reliability and preventing supply chain interruptions. Companies must address the growing data privacy concerns. In truth, over a quarter have already prohibited generative AI tools due to these perils.

AI spending in procurement is projected to increase by 46% by 2026. This increase highlights the importance that AI will have on sourcing strategies moving forward. Balancing innovation with compliance and privacy will be the necessary foundation of trust and stability.

Emphasis on Innovation and Collaboration

Partnership and creativity are becoming the lifeblood of sourcing optimization. Today, procurement teams are more often than not working hand-in-hand with suppliers to co-develop solutions, optimize processes, and reach mutually beneficial goals.

By 2025, 80% of businesses intend to factor ESG (Environmental, Social, and Governance) considerations into their sourcing decisions. This move is changing the nature of supplier relationships and accelerating the movement toward sustainable sourcing practices.

Technologies like ProQsmart facilitate real-time collaboration and transparency allowing private and public enterprises to meet sustainability goals while innovating. These types of collaborative initiatives create more than just public procurement benefits, but lay the groundwork for long-term value creation for all stakeholders.

Agile Supplier Relationship Management

As the market continues to change, being agile and efficient in managing supplier relationships will be key. Agile procurement is based on real-time data, continuous communication, and agile strategies to pivot quickly according to market fluctuations.

Advanced e-sourcing tools such as ProQsmart give organizations the ability to monitor supplier performance and manage bills of quantities. These systems further empower them to stay compliant despite constantly evolving regulations.

In fact, data analytics is essential to the supplier selection and performance evaluation process. It allows companies to find the partners that best fit their strategic objectives. Companies that use ProQsmart save a ton of money. They too are enjoying better reliability from their suppliers, demonstrating the real, sweat-in-the-eye effects of agile relationship management.

Enhance Manufacturing Sourcing Processes

Sourcing optimization software is key to fortifying manufacturing operations and winning a lasting competitive advantage. It’s a proactive, perpetual practice that keeps companies agile and capable of responding to constantly-evolving market conditions. Staying focused on data-driven solutions helps streamline the sourcing process and decision making.

In fact, it can reduce the time needed to analyze and evaluate sourcing options by 90% or more! This level of efficiency not only streamlines operations, it greatly increases productivity. It improves supply chain resilience, which is increasingly important in today’s volatile landscape.

For example, using solutions such as ProQsmart’s advanced sourcing software optimization tools makes it easier to manage and optimize complex scenarios. With pre-built low-cost baselines, evaluating supplier options becomes as easy as pushing a button. Such technology enables manufacturers to test dozens of different supplier selections in just minutes, delivering strategic insight without slowing down the process.

In addition, strategies such as single sourcing can deepen connections with suppliers, providing more favorable pricing and delivery dependability. By eliminating cycle times and increasing visibility, sourcing optimization fosters collaboration and control enterprise-wide, end-to-end.

Conclusion

Sourcing optimization powers more successful outcomes in manufacturing. It enhances supplier collaboration, lowers costs, and leads to frictionless operations. Through a combination of actionable strategies and workflow optimizing tools, you can meet the increasing demands and establish impactful and productive processes. With the right approach, you can anticipate shifts in market trends and pivot to meet evolving customer demands without missing a beat.

Taking the time to get sourcing optimization right will lay the groundwork for sustained success. It encourages more sustainable growth patterns, maintains transparency in the process, and improves the quality of decision-making. Being informed and being proactive keeps you ahead of the competition.

So whether you’re honing your craft or finding new avenues to amplify your work, every step makes a difference. Get started today with ProQsmart’s sourcing solutions by scheduling a demo today, and discover the difference it can make to achieving your manufacturing ambitions.

FAQs

What is sourcing optimization?

Sourcing optimization software removes guesswork from the sourcing process and procurement strategy. This practice not only lowers costs but also enhances sourcing effectiveness and creates better quality products. Tools such as ProQsmart facilitate manufacturing companies in achieving their strategic sourcing decisions through informed, data-driven evaluations.

How does ProQsmart support sourcing optimization?

ProQsmart revolutionizes procurement processes through sourcing optimization software that integrates advanced analytics, supplier evaluations, and cost modeling, helping manufacturers enhance sourcing effectiveness and improve procurement efficiency.

Why is sourcing optimization important in manufacturing?

Sourcing optimization software aids manufacturers in reducing costs and strengthening supply chain reliability while enhancing sourcing effectiveness. This modern optimization esourcing software solution fosters productive supplier relationships, fueling long-term business growth.

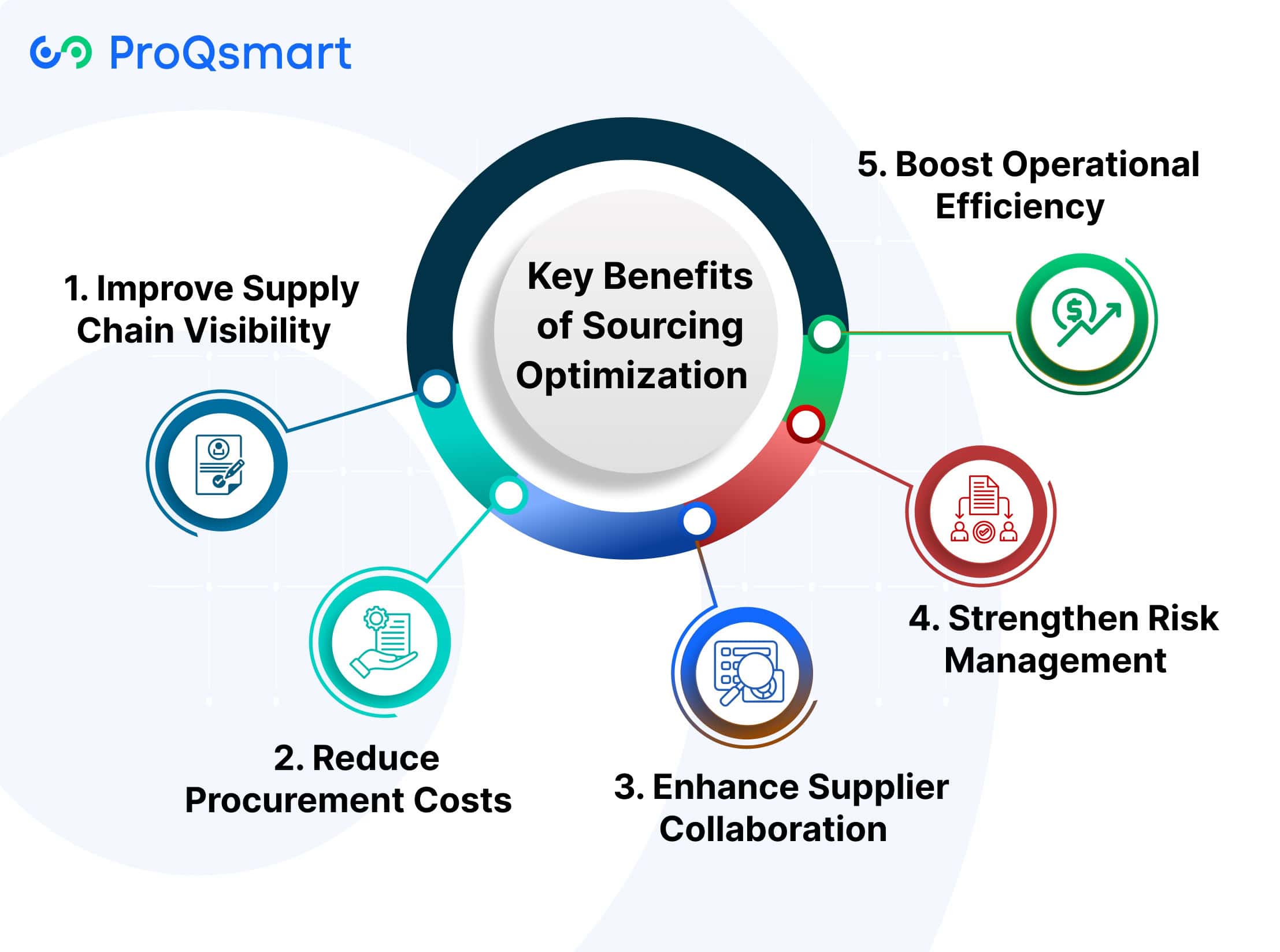

What are the key benefits of using sourcing optimization tools?

Tools like ProQsmart, a modern optimization e-sourcing software solution, provide advantages including lower costs and greater supplier reliability. By enhancing the sourcing process and utilizing sourcing optimization software, they develop deeper supply chain resiliency and improve the speed of decision-making for manufacturers.

What challenges can ProQsmart help overcome in sourcing optimization?

ProQsmart’s AI revolutionizes procurement processes by eliminating inefficient supplier evaluation and automating manual procurement workflows. It delivers data-driven solutions that enhance sourcing optimization software, maximizing sourcing effectiveness and improving overall supply chain performance.

How can manufacturers implement sourcing strategies effectively?

By taking advantage of sourcing optimization software like ProQsmart, manufacturers can enforce smart sourcing practices. These modern optimization esourcing software solutions provide visibility across supplier capabilities, streamline cost structures, and enhance sourcing effectiveness to comply with procurement objectives.

What are the future trends in sourcing optimization?

Looking ahead, we can expect to see a stronger reliance on AI-driven analytics and sourcing optimization software, alongside sustainability-focused sourcing efforts and more automation throughout the procurement process. With innovations like these, ProQsmart continues to stay one step ahead to empower manufacturers and enhance sourcing effectiveness.

- In manufacturing, materials and components have a direct impact on production schedules and production quality. These reasons make sourcing optimization a crucial component of winning a lasting competitive advantage.

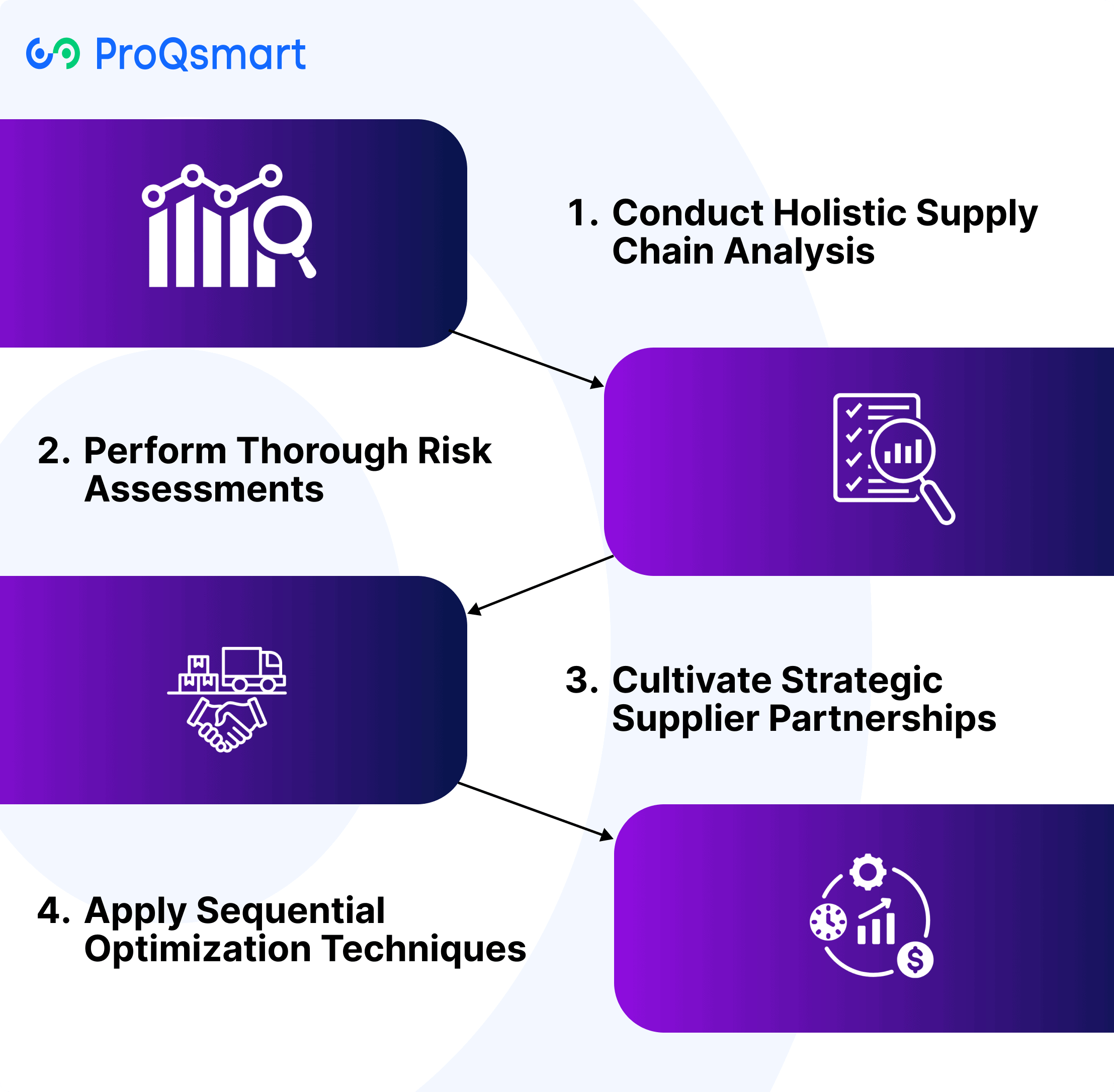

- Key components of sourcing optimization include detailed cost analysis, where procurement teams examine spending patterns and identify cost-saving opportunities. Supplier performance evaluation ensures suppliers meet quality standards and delivery timelines. Risk assessment helps anticipate potential disruptions, such as supply shortages or geopolitical factors, ensuring contingency plans are in place.

- Advanced tools like ProQsmart enable organizations to analyze multiple scenarios rapidly, offering insights that reduce reliance on manual spreadsheets while saving up to 85% of time spent on sourcing decisions.

- Preparation for effective implementation starts with visibility, because knowing what the supply chain looks like is the key first step. Cloud-based solutions make this much easier, delivering real-time data on supplier performance and costs across the board.

- AI-powered tools analyze historical data to help recommend the best possible suppliers. They laser in on priorities, like making sure that 75% of their business goes to the lowest cost vendors. This method reduces the chance of mistakes while automating essential tasks, like contract management, improving operational efficiency.