Supplier management is about strategically managing and optimizing their relationships with their suppliers. This rigorous process keeps us running smoothly, saves taxpayers money, and helps us return value.

By focusing on critical elements like supplier selection, performance evaluation, and risk mitigation, we help organizations build stronger supplier networks that align with their business goals. Strong supplier management encourages collaborative working, greater transparency, and flexibility to adapt to changing market conditions.

By prioritizing procurement risk management and implementing the right strategies, you can proactively protect procurement workflows, reduce disruptions to your operations, and improve supply chain performance.

Effective supplier management combines proven practices with actionable insights, enabling businesses to make informed decisions and drive sustainable growth. In this article, we’ll explore how strategic supplier management can transform procurement into a competitive advantage.

What is Supplier Management?

Supplier management is critical to managing each and every touchpoint with third-party suppliers. Beyond simply maintaining these relationships, it helps them unleash the full potential of the organization’s goals.

It includes planning and administering the complete supplier lifecycle, beginning with selection and onboarding, through performance evaluation and ultimate offboarding. By implementing structured practices, businesses can secure high-quality goods and services while optimizing costs, a critical balance in today’s competitive markets.

Importance of Effective Supplier Management

Proactive supplier management is key to avoiding supply chain risks and cost increases. A smartly managed supplier network limits risks, such as project delays, compliance violations, or disruption in the supply.

Establishing lines of regular communication—even when times are good and everything is operating smoothly—builds trust and helps provide ongoing value. This method ensures a high quality. Plus, it helps you stay compliant with critical emerging regulations like the Supply Chain Act, which addresses requirements for ethical and sustainable sourcing.

Beyond that, effective supplier management plays a key role in driving agility and continuity for the business. By streamlining processes, such as automating workflows or managing supplier data digitally via enterprise content management (ECM) platforms, companies can reduce administrative burdens and shorten procurement cycles.

As an example, ProQsmart provides automated workflows to streamline supplier management processes, track supplier performance, and maintain compliance with industry regulations. Its smart AI-driven features, such as real-time tracking, cost savings, and collaboration, all contribute to making procurement more efficient and transparent.

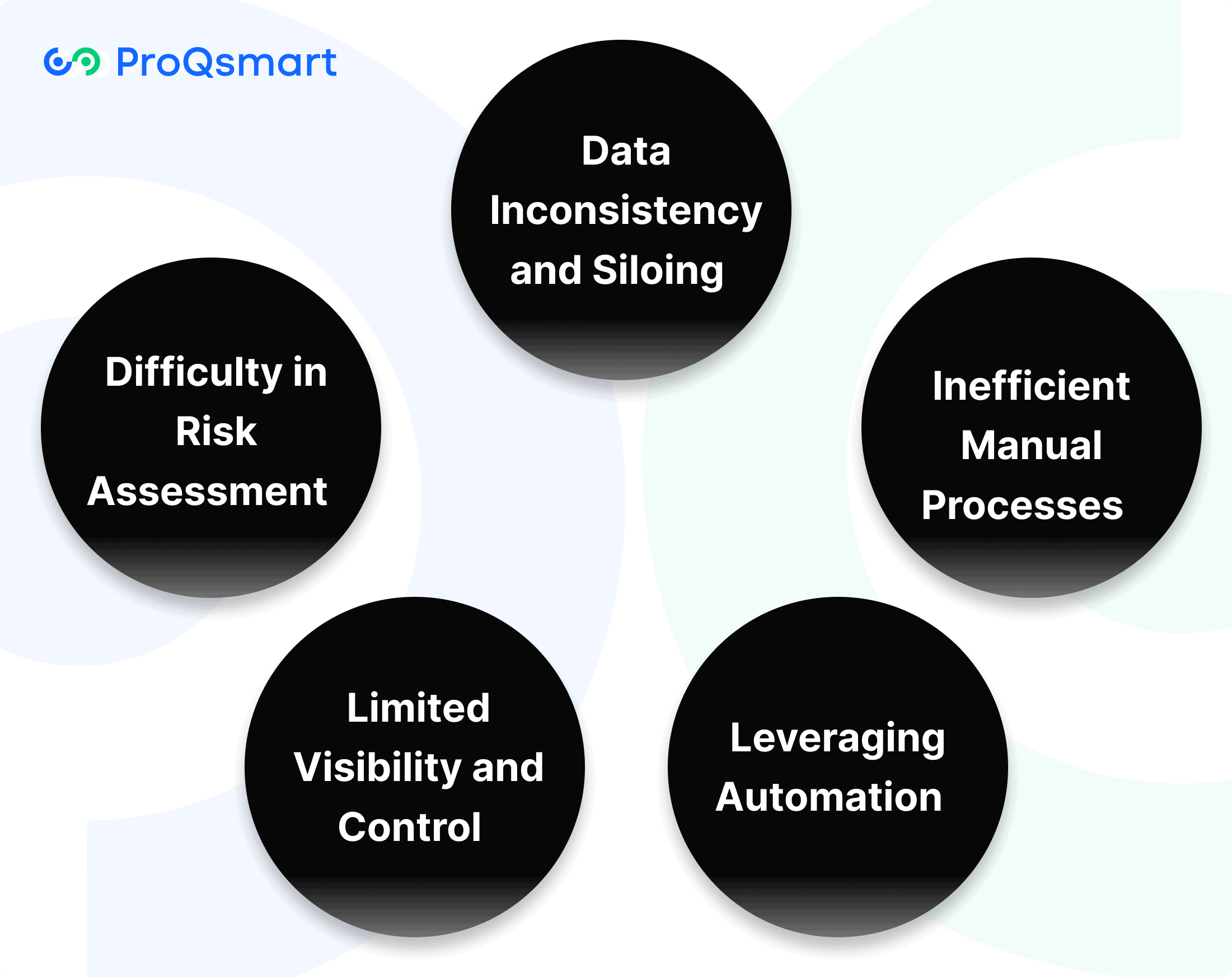

Traditional Supplier Management Challenges

In traditional supplier management processes, a few common, long-standing challenges can hinder procurement teams from operating efficiently and making strategic decisions. These challenges, ranging from disparate data sources to a lack of visibility, create barriers that procurement teams must navigate daily. Overcoming these challenges is crucial to foster mutually beneficial supplier partnerships and enhance supply chain resilience for sustainable success.

Data Inconsistency and Siloing

One major issue is inconsistent and siloed supplier data. When priorities for sourcing differ from department to department, data usually gets siloed, resulting in misaligned decisions. Costly mistakes can occur; for example, a lack of consistent supplier evaluation metrics can lead you to choose an underperforming vendor.

Siloed information doesn’t help collaboration either, with different teams often missing a clear picture of supplier activity. To address this, having supplier data centralized on a shared platform with all applicable stakeholders, such as ProQsmart, makes information more accessible, reliable, and aligned. ProQsmart removes bias through AI-powered supplier dashboards that help organizations identify high-risk suppliers more quickly.

Inefficient Manual Processes

Manual processes are still a key challenge, with procurement teams spending more than a fifth of their time on manual, paper-based processes. Time-consuming onboarding processes and inefficient supplier sourcing through archaic practices add to the problem.

Consider, for instance, the time it takes sourcing professionals to evaluate suppliers, particularly when doing so manually and with often-incomplete data.

Leveraging Automation

Automation is the solution to all of these inefficiencies. ProQsmart automates workflows, including supplier onboarding and ongoing document management, saving your team time and increasing accuracy in supplier management processes.

Limited Visibility and Control

These traditional approaches lack real-time visibility into supplier performance, leaving businesses at greater risk for disruptions. Without strong, resilient tracking systems, teams find it difficult to know what’s changing in the supply chain.

With real-time tracking and performance monitoring, supplied by ProQsmart, businesses are empowered to prevent issues from arising and stay in control.

Difficulty in Risk Assessment

Evaluating supplier risks with a traditional approach usually misses the mark on key issues. Advanced analytics, such as those provided by ProQsmart, enhance supplier management processes by pinpointing weaknesses, maintaining oversight and compliance, and adjusting to economic changes for effective management.

How Does Automated Tools Transform Supplier Management Challenges?

Automated tools, on the other hand, provide a game-changing solution by tackling these unique pain points head-on and with speed and accuracy.

This includes data that is often fragmented in traditional method, with information spread across multiple platforms, making it nearly impossible to proactively track supplier performance or compliance. Poor visibility leads to slower decision-making and higher levels of risk.

For example, without real-time visibility, flagging non-compliance in certifications or notification of missed deadlines is a reactive, time-consuming process.

|

Aspect |

Traditional Methods |

Automated Tools |

|---|---|---|

|

Data Management |

Inconsistent, fragmented data |

Centralized and real-time data access |

|

Decision-Making |

Delayed due to manual analysis |

Data-driven, informed decisions |

|

Risk Management |

Reactive approach |

Proactive monitoring with compliance alerts |

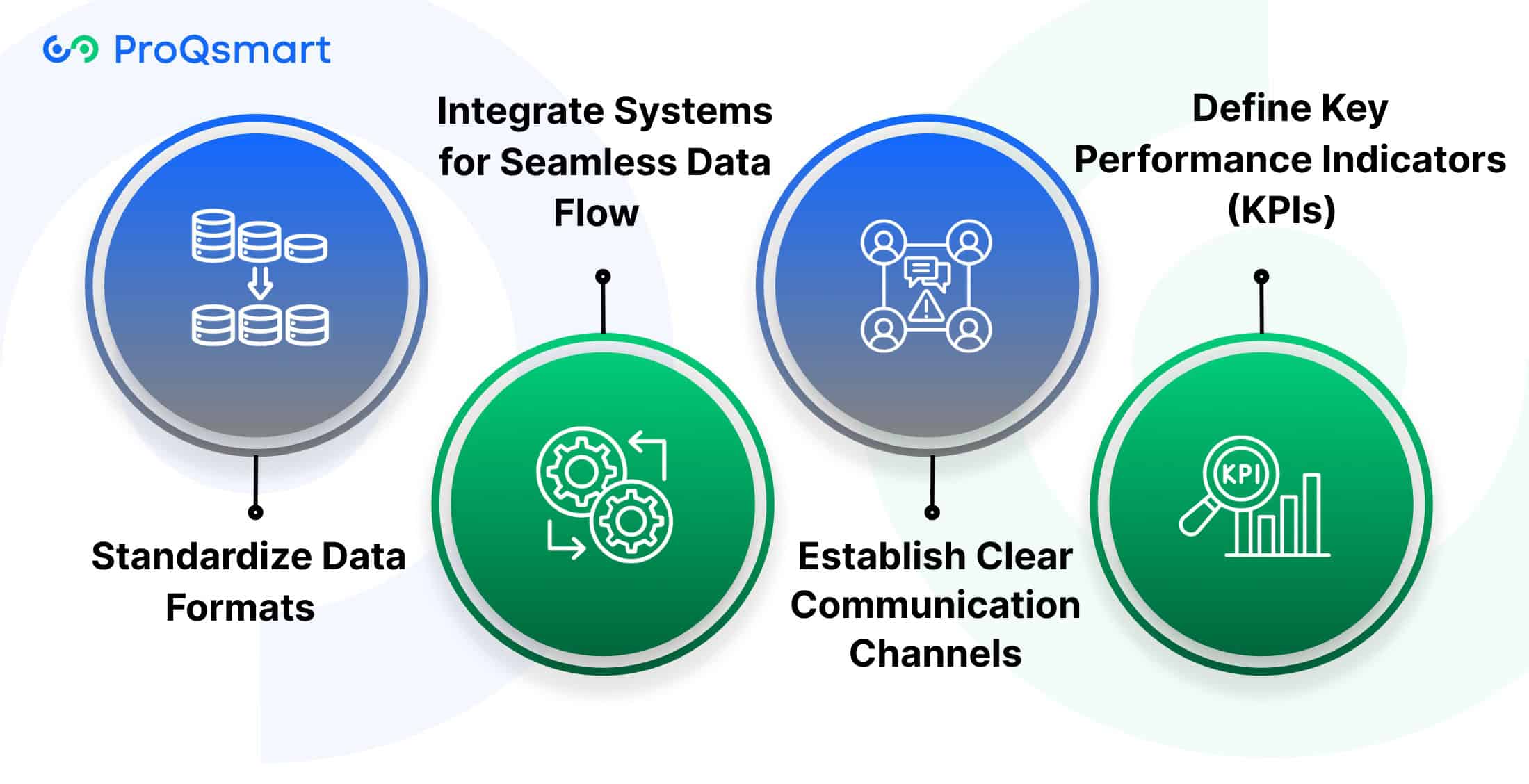

Best Practices for Implementing Automated Tools

When deploying automation, it’s important to note that for automation to work effectively, data formats must be standardized and integrated across all departments.

An all-inclusive platform like ProQsmart can make this transition very easy and straightforward. Its features, such as monitoring supplier performance and tracking regulatory compliance, provide valuable integration with other tools.

Most importantly, they provide an easy fit into current workflows.

Enhancing Supplier Relationships Through Automation

With real-time performance monitoring and collaboration tools, better relationships can be built with key suppliers.

One such example is how automation minimizes the chances of manual error with communication and allows for more effective resource allocation.

Businesses that automate report up to 25% in cost savings. Meanwhile, they achieve greater growth, demonstrating the tangible benefits of improved, simpler processes.

ProQsmart: A Solution for Transformation

ProQsmart is a revolutionary new approach to supplier management processes that directly tackles the difficult challenges we all face in procurement today. Recognized as an industry-leading platform, it leverages automation and data centralization to enhance effective management and foster strategic supplier relationships throughout complex supply chains.

- ProQsmart automates workflows related to pre-qualification and document management. This method reduces lead times by as much as 80% and ensures complete, uniform documentation.

- One of ProQsmart’s standout features is its supplier performance monitoring, which provides actionable insights to consistently evaluate key suppliers. With tools such as scorecards and compliance tracking, businesses can maintain transparency and accountability while mitigating risks like supply disruptions.

- Integration capabilities take ProQsmart’s value to the next level. Their pre-configured compatibility with ecosystems like capital expenditure systems improves connectivity, empowering transformation across global supply chains.

- ProQsmart’s comprehensive feature set, from RFx Management to Sourcing Automation to Autonomous Negotiations, promotes informed collaboration and creates healthier supplier relationships. The platform’s support for open contract negotiations is a direct response to the ambitious goals of 49% of organizations seeking outcomes-based collaborative partnerships.

Best Practices: Implementing Automated Supplier Management

Automated supplier management is, therefore, completely transforming the procurement landscape with improved process efficiencies, seamless collaboration, and better-informed decision-making through effective supplier management processes. To reap these benefits in their entirety, adopting best practices is crucial for ensuring successful supplier relationships in the long term.

- Standardize data formats for consistency across suppliers.

- Integrate systems to ensure seamless data flow.

- Provide comprehensive training for suppliers on automated systems.

Standardize Data Formats

Standardized data formats help establish a single source of truth for SIM, the bedrock of successful supplier management. Standardization minimizes the risk of errors, creates a single point of access, and ensures accurate supplier evaluations.

Standardized data formats make it easier to track metrics that matter most. As an example, Walmart is working towards a goal of 90% on-time and 95% in-full deliveries as a benchmark.

Integrate Systems for Seamless Data Flow

Centralizing procurement systems and leveraging ERP capabilities break down data silos and automate workflows. Real-time data sharing with suppliers is important for building a collaborative relationship while avoiding costly manual errors.

ProQsmart’s AI-driven platform is a perfect example of this by automating workflows, managing subcontractors, and increasing transparency in procurement operations.

Establish Clear Communication Channels

Prompt, clear communication helps establish trust and transparency with your suppliers. Supplier relationship management concepts, such as regular updates and feedback mechanisms, improve communication and foster a collaborative environment.

This approach addresses issues before they become projects.

Define Key Performance Indicators (KPIs)

KPIs such as on-time delivery percentage standards inform supplier performance reviews and drive corrective actions. Implementing effective supplier management processes that align with overall business objectives helps you manage contracts proactively.

Mitigating Risks in Supplier Management

Strong supplier management is a foundational element of resilient procurement practice. Tackle risks head on and drive formal processes to protect your business from future disruptions. Incorporating this mindset, you can build a more consistent, risk-free supply chain.

Read on as we dive into key elements of risk mitigation, pointing out key takeaways for effective supplier management.

Identifying Potential Risks

The first step in addressing supplier risk is to pinpoint where risks exist that could affect your procurement processes.

- Supplier financial health, including the risk of sudden defaults or inability to provide services.

- Supply chain volatility related to global drivers, including geopolitical shifts, climate events, or global health crises.

Developing Risk Mitigation Strategies

A comprehensive risk management strategy is essential. Start by establishing contingency plans to ensure continuity during supplier failures.

Diversifying your supplier base reduces over-reliance on single vendors, mitigating risks tied to specific disruptions. Regular risk assessments allow you to adapt strategies to evolving threats.

ProQsmart, with its AI-driven supplier performance monitoring and compliance tools, streamlines this process, ensuring informed decision-making and operational resilience.

Monitoring and Auditing Supplier Compliance

Supportive, ongoing supervision helps to reinforce supplier connections. Routine audits confirm compliance with contract and legal requirements, and robust oversight systems include monitoring against industry standards and key indicators.

ProQsmart’s real-time collaboration and compliance features simplify these tasks dramatically. This helps keep your supplier base squeaky clean and above board, mitigating risks while increasing efficiency.

Building Strong Supplier Relationships

Developing great supplier relationships can be the key to providing superior quality, reliability and innovation in today’s fast-paced and competitive manufacturing environment. Long-term partnerships create a culture of open idea and feedback sharing that benefits joint operational excellence and strategic fit.

By focusing on trust and collaboration, organizations can proactively mitigate risks, optimize processes, and create a more resilient supply chain.

Fostering Transparency and Trust

Transparency serves as the foundation of any successful supplier relationship. Openly sharing relevant information, such as forecasts and performance expectations, helps suppliers align with your business goals.

This clarity minimizes misunderstandings, enabling swift issue resolution and more efficient workflows. For example, supplier scorecards—used by 80% of companies—track key metrics like on-time delivery and adherence to budgets, promoting accountability.

ProQsmart’s supplier performance monitoring tool excels in this area, offering real-time assessments and insights that reinforce transparency while driving supplier reliability.

Encouraging Collaboration and Communication

Collaboration between buyers and suppliers generates many opportunities for joint problem-solving and innovation. Regular meetings to review performance and set goals strengthen this partnership, ensuring alignment on shared objectives.

In the long run, distributor and supplier alignment through a collaborative approach lowers administrative overhead and cycle times, enabling both parties to focus on more value-driven initiatives.

ProQsmart enables this collaboration with tools including e-tenders and real-time chat functionality, simplifying communication and building supplier confidence.

Implementing Performance-Based Incentives

When you align supplier incentives with your business objectives, it’s a win-win. Performance-based rewards encourage suppliers to go above and beyond and create a willingness to do better with regard to quality and on-time delivery.

Connecting these upsides to real-time metrics monitored via tools such as ProQsmart fosters a culture of perpetual progress and raises supplier accountability.

Conclusion

Supplier management lays the groundwork for more robust operations and improved outcomes. Addressing today’s challenges using yesterday’s tools creates unnecessary inefficiency and missed opportunity. Automated tools make the process easier, less risky, and more transparent so you can use better information to make better decisions. Consider implementing platforms such as ProQsmart to help simplify your operations. With a commitment to best practices, you can develop and maintain suppliers and cultivate effective, sustainable strategic partnerships.

By taking a proactive approach, you can make sure that you’re staying ahead of the curve in an increasingly competitive market. When paired with strong supplier relationships and effective supplier management tools, they open up space for growth, stability, and long-term success. It’s about ensuring each and every step moves you closer to those goals.

Ready to transform your supplier management? Book a demo with ProQsmart today to discover how our innovative solutions can streamline your processes, enhance collaboration, and drive sustainable growth for your business.