In the manufacturing sector, procurement plays a pivotal role in ensuring that production processes run smoothly and efficiently. Effective procurement in manufacturing can significantly impact a company’s bottom line, helping to reduce costs, improve quality, and streamline operations. This comprehensive guide will explore the importance of procurement in manufacturing, key strategies, best practices, and how to optimize procurement processes to achieve business success.

What is Procurement in Manufacturing?

Procurement in manufacturing refers to the process of sourcing and acquiring the raw materials, components, and services necessary for production. It involves negotiating contracts, managing supplier relationships, and ensuring that materials meet quality standards and are delivered on time.

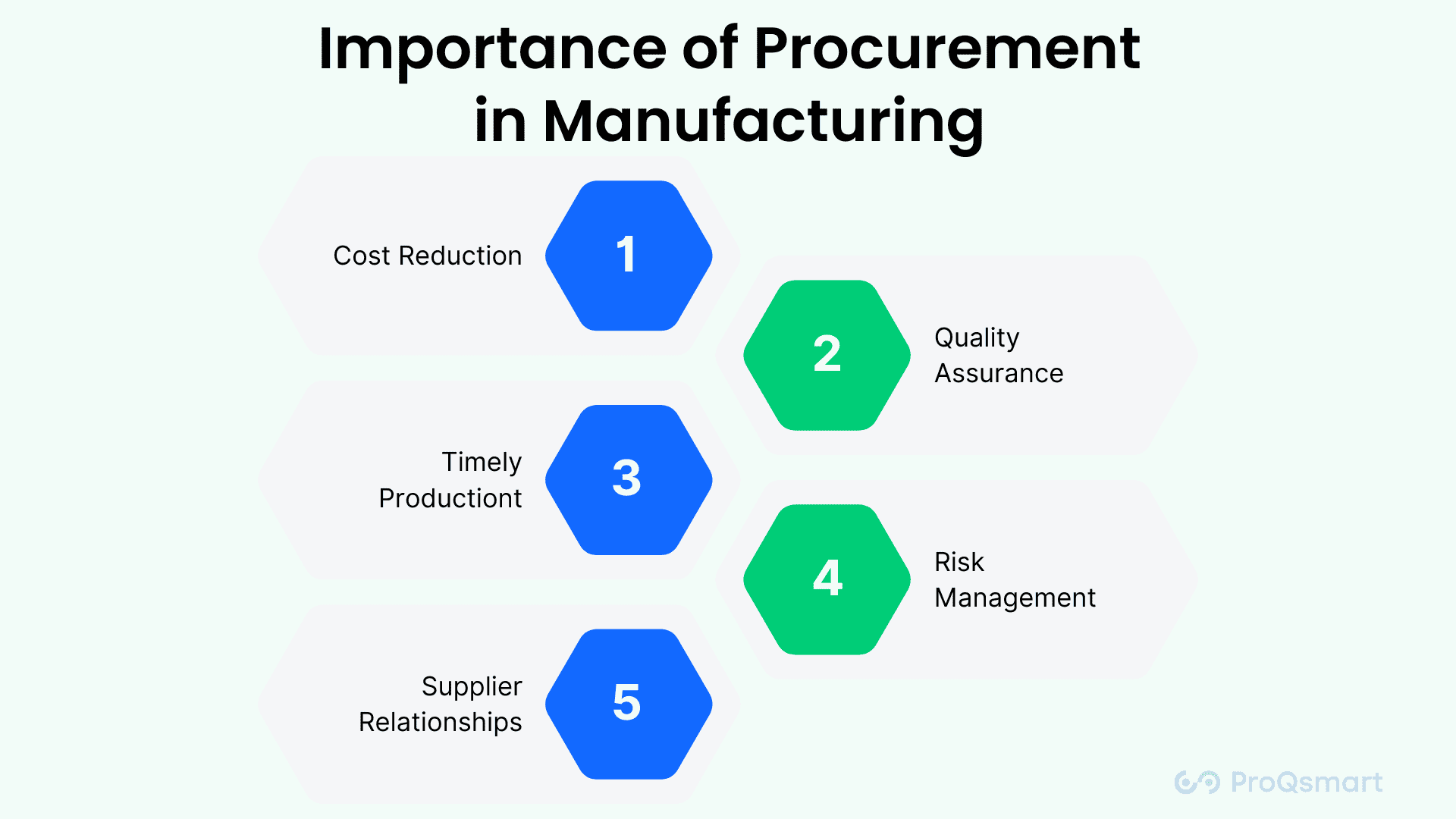

Importance of Procurement in Manufacturing

- Cost Reduction: Efficient procurement helps in negotiating better prices and reducing material costs.

- Quality Assurance: Ensures that materials and components meet quality standards, impacting the final product quality.

- Timely Production: Ensures timely delivery of materials, preventing production delays.

- Risk Management: Identifies and mitigates risks in the supply chain.

- Supplier Relationships: Fosters strong relationships with suppliers for long-term benefits.

Key Strategies for Effective Procurement in Manufacturing

Implementing effective procurement strategies is crucial for manufacturing success. Here are some key strategies to consider:

1. Strategic Sourcing

Strategic sourcing involves identifying and selecting suppliers based on their ability to meet the company’s long-term goals and objectives. It focuses on building long-term relationships rather than short-term gains.

- Supplier Evaluation: Assess potential suppliers based on quality, reliability, and alignment with your company’s values.

- Cost Analysis: Conduct thorough cost analyses to identify the best value for money.

- Market Research: Stay informed about market trends and conditions to make informed sourcing decisions.

2. Supplier Relationship Management

Building strong relationships with suppliers is essential for ensuring a reliable supply of materials. Effective supplier relationship management (SRM) involves regular communication, performance monitoring, and collaboration.

- Regular Communication: Maintain open lines of communication with suppliers to address any issues promptly.

- Performance Metrics: Use key performance indicators (KPIs) to monitor supplier performance.

- Collaborative Planning: Work with suppliers to forecast demand and plan production schedules.

3. Demand Forecasting

Accurate demand forecasting helps in planning procurement activities effectively. By predicting future demand, manufacturers can ensure they have the right materials in the right quantities at the right time.

- Historical Data Analysis: Use historical sales data to forecast future demand.

- Market Trends: Consider market trends and economic conditions in demand forecasts.

- Collaboration: Collaborate with sales and marketing teams to align forecasts with business goals.

4. Risk Management

Identifying and mitigating risks in the supply chain is crucial for maintaining a stable supply of materials. Risk management involves assessing potential risks and developing strategies to address them.

- Risk Assessment: Conduct regular risk assessments to identify potential disruptions.

- Contingency Planning: Develop contingency plans to deal with supply chain disruptions.

- Supplier Diversification: Avoid dependency on a single supplier by diversifying the supplier base.

5. Technology Integration

Leveraging technology can enhance procurement processes by automating tasks, improving data accuracy, and providing real-time insights.

- E-Procurement Systems: Implement e-procurement systems to streamline purchasing activities.

- Data Analytics: Use data analytics to gain insights into procurement performance and identify improvement opportunities.

- Supply Chain Management Software: Utilize supply chain management software to monitor and manage the entire supply chain.

Best Practices for Procurement in Manufacturing

Following best practices can help manufacturers optimize their procurement processes and achieve better results. Here are some best practices to consider:

1. Develop a Clear Procurement Policy

A clear procurement policy provides guidelines for all procurement activities, ensuring consistency and compliance with company standards.

- Policy Documentation: Document all procurement policies and procedures.

- Training: Provide training to employees to ensure they understand and follow the procurement policy.

- Regular Updates: Review and update the procurement policy regularly to reflect changes in business needs and market conditions.

2. Foster Collaboration

Encourage collaboration between procurement, finance, production, and other departments to ensure a holistic approach to procurement.

- Cross-Functional Teams: Create cross-functional teams to work on procurement projects.

- Regular Meetings: Hold regular meetings to discuss procurement strategies and issues.

- Shared Goals: Align departmental goals with overall business objectives.

3. Monitor Supplier Performance

Regularly monitoring supplier performance helps in maintaining quality standards and ensuring timely delivery of materials.

- Performance Reviews: Conduct regular performance reviews with suppliers.

- Feedback Mechanisms: Provide constructive feedback to suppliers and work on improvement plans.

- Incentives: Offer incentives for suppliers who consistently meet or exceed performance standards.

4. Embrace Sustainable Procurement

Sustainable procurement practices help in reducing environmental impact and promoting social responsibility.

- Sustainable Suppliers: Choose suppliers that adhere to sustainable practices.

- Green Procurement: Prioritize the procurement of environmentally friendly products and materials.

- CSR Initiatives: Engage in corporate social responsibility (CSR) initiatives that promote sustainability.

5. Leverage Data and Analytics

Using data and analytics can provide valuable insights into procurement performance and help in making informed decisions.

- Spend Analysis: Conduct regular spend analyses to identify cost-saving opportunities.

- Supplier Data: Maintain detailed data on supplier performance and capabilities.

- Predictive Analytics: Use predictive analytics to forecast demand and identify potential risks.

Conclusion

Optimizing procurement in manufacturing is essential for achieving business success. By understanding the importance of procurement, implementing effective strategies, and following best practices, manufacturers can enhance efficiency, reduce costs, and improve overall performance. Strategic procurement not only supports the company’s financial goals but also contributes to its competitiveness and sustainability in the market.