In today’s competitive business environment, maintaining a strong relationship with suppliers is crucial for operational efficiency and long-term success. A robust supplier relationship can lead to cost savings, improved quality, and enhanced innovation. This comprehensive guide will explore the importance of building and maintaining strong relationships with suppliers, strategies for success, and best practices to foster long-term partnerships.

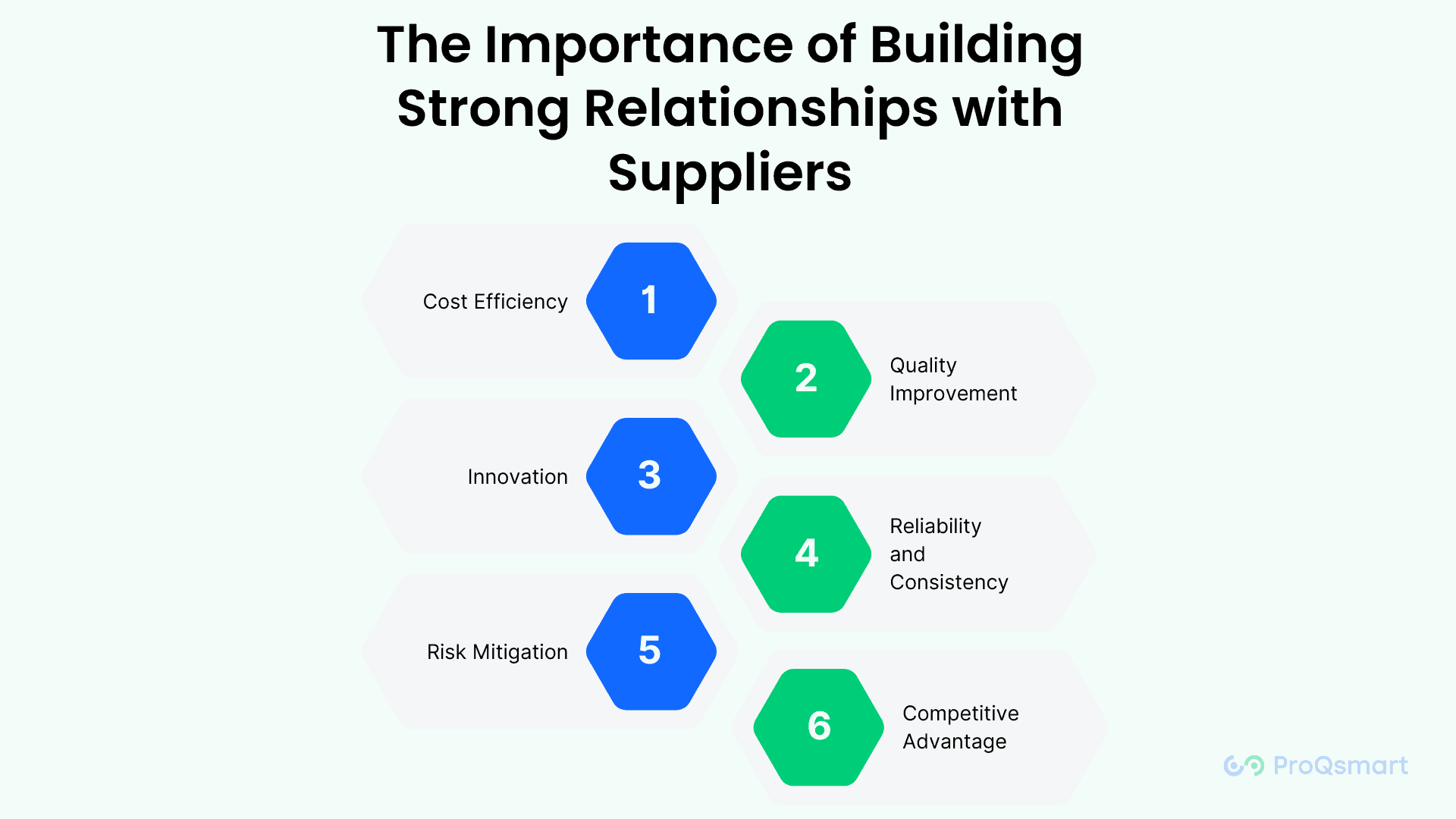

The Importance of Building Strong Relationships with Suppliers

A strong relationship with suppliers goes beyond transactional interactions; it involves collaboration, mutual trust, and shared goals. Here’s why developing strong supplier relationships is essential:

1. Cost Efficiency

Effective supplier relationships can lead to significant cost savings through better pricing, discounts, and more favorable terms. Suppliers may offer better rates to businesses they trust and have a long-standing relationship with.

2. Quality Improvement

Suppliers who understand your business needs are more likely to deliver higher quality products and services. Collaboration can lead to improvements in materials, processes, and overall product quality.

3. Innovation

Strong supplier relationships foster collaboration and innovation. Suppliers are more likely to share new technologies, products, and process improvements with trusted partners.

4. Reliability and Consistency

Reliable suppliers ensure consistent delivery of materials and services, reducing the risk of production delays and disruptions. This reliability is built on a foundation of strong relationships.

5. Risk Mitigation

Good relationships with suppliers can help mitigate risks such as supply chain disruptions, regulatory changes, and market fluctuations. Suppliers may prioritize your needs during times of scarcity or crisis.

6. Competitive Advantage

Businesses that manage supplier relationships effectively can achieve a competitive advantage through cost efficiency, innovation, and improved quality, enhancing their market position.

Key Strategies for Building Strong Relationships with Suppliers

Building and maintaining strong relationships with suppliers requires strategic planning and ongoing effort. Here are some key strategies to consider:

1. Clear Communication

Effective communication is the cornerstone of any strong relationship. Maintain open lines of communication with your suppliers, ensuring transparency and clarity in all interactions.

- Regular Updates: Provide regular updates on your business needs and any changes in requirements.

- Feedback Loop: Establish a feedback loop to address any issues and continuously improve the relationship.

2. Collaborative Planning

Collaborative planning involves working closely with suppliers to align on goals, forecasts, and expectations. This joint planning helps ensure that both parties are on the same page and can work together effectively.

- Joint Forecasting: Share forecasts and demand plans with suppliers to help them plan their production and inventory.

- Mutual Goals: Set mutual goals and objectives to drive collaboration and joint success.

3. Performance Monitoring

Regularly monitor and review supplier performance to ensure they meet your standards and expectations. Use key performance indicators (KPIs) to track performance and address any issues promptly.

- KPIs: Define clear KPIs such as delivery time, quality, and cost performance.

- Performance Reviews: Conduct regular performance reviews and provide constructive feedback.

4. Long-Term Commitment

Demonstrate a long-term commitment to your suppliers by establishing multi-year contracts and partnerships. This stability can encourage suppliers to invest in improvements and innovations that benefit both parties.

- Long-Term Contracts: Establish long-term contracts to provide stability and predictability.

- Partnership Programs: Develop partnership programs that reward suppliers for long-term collaboration and performance.

5. Fair Negotiations

Negotiate fairly with your suppliers, ensuring that both parties benefit from the agreement. Avoid aggressive tactics that may damage the relationship and focus on creating win-win scenarios.

- Transparent Negotiations: Be transparent about your needs and constraints during negotiations.

- Mutual Benefits: Seek to create agreements that provide mutual benefits and shared value.

6. Technology Integration

Leverage technology to enhance collaboration and streamline processes. Implement digital tools and platforms that facilitate communication, data sharing, and performance monitoring.

- E-Procurement Platforms: Use e-procurement platforms to manage transactions and communications.

- Data Analytics: Employ data analytics to gain insights into supplier performance and identify areas for improvement.

7. Ethical and Sustainable Practices

Promote ethical and sustainable practices in your supplier relationships. Encourage suppliers to adopt environmentally friendly practices and adhere to ethical standards.

- Sustainability Initiatives: Collaborate with suppliers on sustainability initiatives.

- Ethical Standards: Ensure that suppliers comply with ethical standards and labor practices.

8. Conflict Resolution

Establish effective conflict resolution mechanisms to address any disputes or issues that arise. A proactive approach to conflict resolution helps maintain positive relationships.

- Dispute Resolution: Develop clear processes for resolving disputes and addressing issues.

- Mediation and Negotiation: Use mediation and negotiation to find mutually acceptable solutions.

Best Practices for Maintaining Strong Supplier Relationships

Maintaining strong supplier relationships is essential for organizations looking to optimize their procurement processes and enhance overall operational efficiency. In the technology sector, where rapid changes and innovation are the norms, effective collaboration with suppliers can lead to significant competitive advantages. Here are some best practices specifically tailored for the technology industry:

1. Clear Communication

Establishing open and transparent communication channels is vital. Regularly updating suppliers about project requirements, changes in specifications, and timelines helps to build trust and ensures that everyone is aligned. Utilizing technology platforms can facilitate this communication, allowing for real-time updates and feedback.

2. Leverage Technology Solutions

Investing in robust procurement and supplier management tools can streamline interactions and improve efficiency. Platforms like ProQsmart offer comprehensive solutions for managing supplier relationships, tracking performance metrics, and ensuring compliance with contractual obligations. By using such tools, organizations can automate routine tasks, freeing up time for strategic relationship-building activities.

3. Collaborative Planning

Engaging suppliers in the planning process fosters a sense of partnership. Involve them early in discussions about product development or project timelines to leverage their expertise and insights. This collaborative approach can lead to innovative solutions that benefit both parties.

4. Performance Evaluation and Feedback

Regularly assess supplier performance against agreed-upon metrics such as quality, delivery times, and responsiveness. Providing constructive feedback helps suppliers improve their services while also reinforcing accountability. ProQsmart can assist in tracking these metrics effectively, enabling data-driven discussions during performance reviews.

5. Foster Long-Term Partnerships

Instead of viewing suppliers as mere transactional entities, cultivate long-term relationships by investing in partnerships. This could involve offering training opportunities, sharing market insights, or collaborating on joint ventures. Strong partnerships can lead to better pricing, priority service, and shared innovation.

6. Adaptability and Flexibility

In the fast-paced technology sector, changes are inevitable. Being adaptable to shifts in market demand or technological advancements is crucial. Maintain an open dialogue with suppliers about potential changes and be willing to adjust agreements as necessary to accommodate new realities.

7. Recognize and Reward Excellence

Acknowledging suppliers who consistently perform well can strengthen relationships significantly. Consider implementing a recognition program that highlights outstanding contributions from suppliers, which can motivate them to maintain high standards.

Conclusion

Building and maintaining strong relationships with suppliers is crucial for business success. By implementing the strategies and best practices outlined in this guide, you can enhance collaboration, improve quality, and achieve cost efficiency in your supply chain operations. Strong supplier relationships not only benefit your business but also contribute to a more resilient and innovative supply chain.

Utilizing technology can significantly bolster these relationships. For instance, ProQsmart offers comprehensive solutions for managing supplier interactions, tracking performance metrics, and ensuring compliance. By leveraging ProQsmart, you can streamline communication and automate processes, allowing for more strategic engagement with your suppliers.

To see how ProQsmart can transform your supplier management and procurement processes, we encourage you to book a demo today. Experience firsthand the benefits of a robust supplier relationship management platform and take the first step toward optimizing your supply chain operations!

FAQs

Why is building a strong relationship with suppliers important?

Building a strong relationship with suppliers is important because it leads to cost efficiency, quality improvement, innovation, reliability, risk mitigation, and a competitive advantage.

What are the key strategies for building strong relationships with suppliers?

Key strategies include clear communication, collaborative planning, performance monitoring, long-term commitment, fair negotiations, technology integration like ProQsmart, ethical practices, and conflict resolution.

How can I maintain regular communication with suppliers?

Maintain regular communication through meetings, calls, emails, and using digital tools like e-procurement platforms to facilitate continuous interaction and updates.

What are some best practices for maintaining strong supplier relationships?

Best practices include regular communication, recognition and rewards, continuous improvement, flexibility, transparency, trust, and investment in training and development also leveraging software or tools like ProQsmart to automate all this process.

How can I handle conflicts with suppliers effectively?

Handle conflicts effectively by establishing clear dispute resolution processes, using mediation and negotiation, and seeking mutually acceptable solutions.