RFx processes, including Requests for Information (RFI), Proposals (RFP), and Quotations (RFQ), offer a structured approach to gathering critical information from suppliers. By leveraging RFx, procurement teams can efficiently identify and select suppliers that meet specific project needs, ensuring that materials and services are both high-quality and cost-effective.

In interior fit-out projects, where customization and quality are paramount, RFx processes help streamline supplier selection by providing a uniform and standardized base for comparing supplier capabilities and ensuring competitive pricing. This article will explore how to effectively use RFx in interior fit-out projects, providing practical tips to enhance procurement efforts and build stronger supplier relationships.

RFx in Interior Fit-Out Projects

Interior fit-out projects involves careful management and integration of craftsmanship, uniqueness, and standards are required. Such projects can easily require coordination with dozens of different suppliers and materials, all requiring different specifications.

RFx processes offer a defined, multi-step approach to addressing these intricacies. They provide a structured approach to source, evaluate and select vendors.

Sourcing Unique Materials/Services

Good sourcing in interior fit-outs starts with developing RFx documents that speak to the right audience. These documents draw in the best-fit vendors with precision by specifying your needs and the scope of work expected.

For instance, standardized RFQs or RFPs simplify procurement by ensuring consistency across submissions, saving time and effort. Smart tools like ProQsmart automate workflows, manage document distribution, and greatly improve transparency, making sure that your vendors truly match what your project needs.

Besides, by including specific technical criteria like material grades or design finish, this eliminates confusion and helps deliver the project goals more effectively. By limiting the RFx process to 3–6 vendors, the response quality is much higher, saving time in evaluation and negotiation.

Managing Quality and Customization

Quality assurance and unique project demands only camouflage the need for strict, rigorous RFx requirements. Adding quality metrics directly into the evaluation of submissions will hold vendors accountable to the standards they set.

For instance, monitoring supplier performance after contract award ensures that suppliers remain committed to fulfilling their obligations. ProQsmart enables continued communications with suppliers, allowing for real-time changes to one-off customization requests.

Its bill of quantities feature allows for easy administration of any changes to materials, preventing any costly hold-ups.

Ensuring Project Compliance

Compliance is therefore key, as interior fit-outs have to comply with maintenance regulations and contractual requirements. RFx processes, combined with RFx technology providers like ProQsmart, identify and collect compliance information in one place, making your project always audit-ready.

Conducting consistent audits and reviews during the entire project lifecycle ensures that design and construction remain aligned with the established requirements, minimizing risks and improving project outcomes.

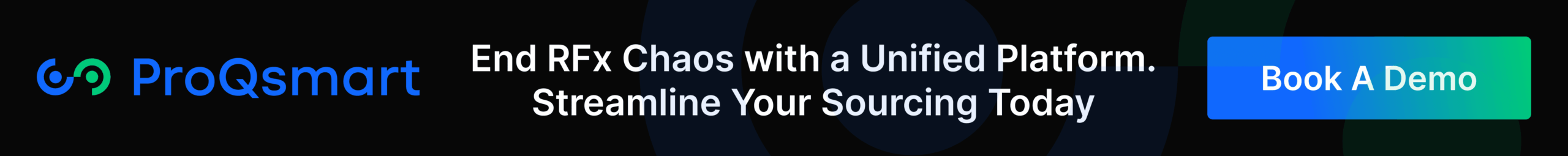

RFI, RFP, and RFQ: Key Differences

Knowing the differences between RFI, RFP, and RFQ is key to using the appropriate one to maximize your procurement strategy. These three documents make the process of engaging with a supplier infinitely easier by meeting highly specific needs at various points in the procurement life cycle.

Below is a detailed comparison:

|

Type |

Definition |

Format |

|---|---|---|

|

Gathers general information about suppliers’ capabilities and solutions. |

Broad questions focusing on supplier expertise, services, and general qualifications. |

|

|

Solicits detailed proposals addressing specific project requirements, including scope. |

Includes scope, technical specifications, deliverables, and evaluation criteria. |

|

|

Requests pricing for clearly defined products or services. |

Specifies quantities, pricing, deadlines, and terms. |

Each one of these documents is different in detail. The difference might seem small, but consider that an RFI requires a general description while RFQs require detailed cost estimates.

RFPs dive deeper into project strategies, often resulting in unique vendor proposals or partnerships to meet requirements.

Choosing the Right RFx Method

Choosing the right RFx comes down to your project’s needs. For early-stage exploration, RFIs can be a gold mine for understanding what the private sector is capable of.

For more complicated projects, RFPs can provide creative perspectives, although 80% of procurement plans use them at least some of the time. RFQs, the approach of choice for 60% of teams, are ideal for apples-to-apples pricing.

ProQsmart takes the guesswork out of these important, complex decisions. With AI-driven tools for e-tendering, supplier management, and cost optimization, you can align your RFx approach to your budget and operational goals while fostering compliance and transparency.

Crafting an Effective RFx Strategy

Creating a successful RFx strategy starts with identifying the specific needs of your organization and how they align with the procurement process. The RFx—whether it’s an RFI, RFP, RFQ, or another type—serves as a structured way to solicit information, proposals, or pricing from suppliers.

To maximize its effectiveness, a well-defined strategy is essential, ensuring that every step contributes to the broader goals of your business.

Define Project Scope and Needs

Key elements to outline include:

- Identify what you aim to achieve with the RFx process.

- Deliverables: Specify the expected outcomes to avoid ambiguous responses.

- Set realistic deadlines for both internal teams and suppliers.

Making sure you are in sync with higher-level organizational goals and budgetary limitations is key. For instance, if cost savings is your most important goal, stress that priority in your scope of work so you are able to direct vendor responses accordingly.

According to industry insights, eight out of ten procurement managers deal with confusing RFIs. This difficulty usually comes from a lack of effort upfront to clarify project requirements. Combat this by holding supplier Q&A webinars or providing comprehensive FAQs.

Identify Potential Suppliers

A more strategic approach to identifying suppliers makes the RFx process much more robust. Begin by using your current supplier database, or use a system such as ProQsmart which simplifies supplier management and increases transparency at the same time.

Reducing the pool down to three to six suppliers both increases the quality of responses received and makes for more effective negotiations. Bringing in a wider range of suppliers increases innovation and competition.

Develop Clear Evaluation Criteria

Providing standardized evaluation criteria to the general public ensures fairness and transparency. Focus on key metrics such as:

- Pricing: Align bids with your budget.

- Experience: Assess past performance and relevant expertise.

- Quality: Evaluate the proposed solutions’ viability.

Work together with cross-functional teams to bring in diverse viewpoints, making sure that it ties back to overarching business goals. Tools such as ProQsmart streamline evaluation by automating workflow and effectively rating supplier performance.

Challenges in Traditional RFx Process in Interior Fit-out

-

Vague requirements lead to mismatched bids, as unclear material specs or design intent cause suppliers to propose generic solutions.

-

Manual processes for managing hundreds of vendors result in errors, inconsistency, and difficulty enforcing quality standards for custom materials.

-

Delays cascade quickly—one supplier’s misstep disrupts timelines and inflates costs across the entire project.

-

Inflexible evaluation criteria fail to prioritize niche needs (e.g., fire safety, acoustics), leading to suboptimal vendor selection.

-

Lack of transparency in traditional RFx processes prolongs procurement cycles with endless clarification rounds and rework.

Over 75% of firms now use e-sourcing tools like ProQsmart to automate workflows, enforce specifications, and significantly reduce procurement timelines by up to 90%, enhancing their procurement processes.

How E-Sourcing Platforms Improve RFx

E-sourcing platforms have transformed the pre-qualification RFx processes by streamlining processes, eliminating inefficiencies and providing a collaborative environment. Revolutionizing Procurement Management Platforms like ProQsmart are revolutionizing procurement management. They centralize all data, automate complex workflows and ultimately equip teams with more advanced tools.

Here’s a look at their most salient features and advantages.

Centralized Information Hub

A centralized information hub helps guarantee that all RFx documents, communications, and updates live in one easily accessible place. Besides, by establishing this single source of truth, it helps to reduce miscommunication and duplication of efforts.

We’ve found that cloud-based platforms enable easy, convenient sharing and collaboration of RFx materials, giving all stakeholders the ability to access vendor-specific, current information in real-time. For example, ProQsmart’s seamless cloud integration facilitates robust document management and tracking, increasing transparency by making it easy to see the history of changes or updates to documents.

Automated Workflows

Automation eliminates the risk of manual mistakes and simplifies repetitive tasks such as bid evaluation or compliance checking. This frees procurement teams to prioritize strategic initiatives.

ProQsmart automates each stage of your process. It automatically generates tailored RFx templates and tracks supplier performance, optimizing both efficiency and accuracy across all stages of the process.

Enhanced Communication Tools

Strong communication tools help fill in the gaps that exist between buyers and suppliers. Real-time commenting, built directly into platforms such as ProQsmart, allows for up-to-the-minute conversations, and structured feedback loops guarantee there’s always room for improvement.

These tools make it easy to negotiate with vendors, especially with ProQsmart’s short-form RFPs that lower vendor response times.

Data-Driven Decision Making

Powerful data analytics and advanced data visualization tools integrated into e-sourcing platforms help procurement teams to make informed decisions. RFx data then provides a foundation for teams to better understand trends, supplier performance, and cost-saving opportunities.

ProQsmart’s AI capabilities take decision-making to a new level by ensuring procurement strategies are fully aligned with organizational goals.

Best Practices for RFx Success

A tiresome and poorly designed RFx process is detrimental to finding the best suppliers and making sure that you are strategically aligned with your procurement objectives. Implementing best practices can help you get the most efficiency and effectiveness out of your RFx efforts. This method increases efficiency and encourages cooperation and transparency.

Here’s a closer look at some practical tactics you can implement to find RFx success.

Standardize Evaluation Criteria

Standardizing evaluation criteria ensures fairness and consistency in vendor assessments. Organizations often follow a structured five-step process, starting from defining requirements to final vendor selection.

A clear scoring system helps in objectively comparing suppliers, focusing on how their solutions meet strategic goals versus their functionality. Communicating these criteria upfront builds trust and allows vendors to tailor their proposals effectively.

For instance, sharing your payment solution’s volumes and geographic reach enables vendors to present relevant, customized solutions.

Emphasize Clear Communication

Strong, clear communication is the lifeblood of a successful RFx process. Frequent communication, uniform submission templates, and clear instructions streamline the process and help cut down on confusion.

Imagine an RFP 10 questions long focusing on the core components of a partnership. Cut time and work down for both sides. This method sharpens overall response quality and enhances decision-making speed.

ProQsmart improves team communication and collaboration through real-time collaboration, automated workflows, and centralized document management.

Use Performance Metrics

Establishing and monitoring performance metrics such as cost savings, improvements in supplier responsiveness, and mitigating risk gives you tangible metrics to work with.

Dashboards and reporting tools, such as those offered by ProQsmart, make it easier to visualize this data, informing smarter future sourcing decisions.

Foster Supplier Collaboration

Strong supplier relationships should be a strong driver for innovation, creativity, efficiency, and flexibility. Engagement through open dialogue and involving suppliers early in the RFx process helps to align expectations and leads to better outcomes for both parties.

ProQsmart’s supplier performance monitoring and subcontractor management tools are perfect for developing and fostering these relationships.

Measuring RFx Initiative Success

Whether it’s an RFx initiative or any other procurement process, measuring success is key to ensuring that the procurement team is effective and truly delivers value. By developing measurable metrics, frameworks, and feedback loops, you can create a structured approach that not only measures success but also builds momentum for continuous improvement.

Key Performance Indicators (KPIs)

Developing KPIs is the first step in any effort to measure RFx success. Metrics such as cost savings, supplier response rates, vendor satisfaction, and quality of materials can give a quick picture into performance. For example, monitoring time-to-market can provide an understanding of how quickly your RFx processes are able to respond to business needs.

By aligning these KPIs with broader procurement objectives, you can ensure that they are in service to more strategic goals. Consistently collecting, tracking, and publicly sharing these metrics enables fact-based decision-making and advocacy. Digital tools such as ProQsmart help track in real-time and increase transparency.

Cost Savings Analysis

Therefore, cost savings is still the most important measure of RFx success. By measuring the difference between the original supplier quotes and what is contracted in the end, you can measure savings that truly illustrate procurement’s value.

Employing cost analysis tools makes it much easier to present findings to stakeholders, while maintaining clarity and precision. ProQsmart’s budget-driven procurement functionality reconciles spending with financial objectives, providing even deeper visibility into cost containment.

Time Efficiency Gains

Measuring cycle times shows how process improvements can increase efficiency in RFx processes. Shorter lead times means projects can be delivered faster, which in turn leads to better operational performance.

Regularly tracking these metrics will reveal where the bottlenecks are occurring and where workflows can be improved. ProQsmart’s automated workflows make quality assurance more efficient, leaving leaders to focus time and money on what’s most strategic.

Supplier Performance Evaluation

Post-RFx evaluations ensure supplier accountability. Measuring adherence to these metrics, especially about quality and delivery time, helps set the stage for future engagements.

By making it easier to monitor supplier performance, ProQsmart makes it possible to conduct regular reviews and encourage collaborative improvements.

Conclusion

The rules of a thoughtfully constructed RFx process lay the groundwork for subsequent interior fit-out projects to thrive, producing desirable, collaborative, brand-enriching environments. It is the compass that provides clarity, structure, and direction to sourcing efforts. Know the function of each RFx type. Enlist technology tools such as e-sourcing platforms to streamline workflows, curtail time lags, and enhance stakeholder collaboration. Addressing the pain points in outdated bidding processes with today’s technology makes the process easier and more successful for you and with suppliers.

Achieving success in RFx requires intentional design, ongoing measurement, and building in best practices that meet the unique objectives of each project. Measuring your results gives you the information to adjust and improve future initiatives and continue winning in a competitive environment.

To take your RFx management to the next level, consider adopting solutions like ProQsmart. ProQsmart offers a comprehensive platform designed to streamline RFx processes, simplify proposal evaluation, and ensure compliance throughout. By automating workflows and enhancing collaboration, you can drive better procurement outcomes and set your organization up for long-term success. Schedule a demo today!

FAQs

What does RFx mean in interior fit-out projects?

How is RFx used in interior fit-out procurement?

What are the key differences between RFI, RFP, and RFQ?

- RFI: Gathers general information from vendors.

- RFP: Requests detailed proposals for specific project needs.

- RFQ: Focuses on pricing and cost breakdowns.

Each serves a unique purpose in the procurement process.