RFx is short for Request for x. The “x” can stand in for various procurement documents, like RFP (Request for Proposal), RFQ (Request for Quotation) or RFI (Request for Information). These documents are invaluable tools for procurement professionals to help standardize communication between suppliers, fairly evaluate potential suppliers, and source supplies competitively.

RFx processes help organizations clarify requirements, gather detailed supplier information, and make informed purchasing decisions. Including RFx strategies increases transparency and makes it easier to compare suppliers. Abiding by structured templates allows businesses to automate processes and workflows, effectively saving time and cost.

Concise and effective documentation encourages more productive collaboration between buyers and suppliers, driving deliverable compliance and minimizing risk. Mastering RFx processes is essential to getting the most out of your procurement strategy and developing long-term supplier relationships. This article will delve into the intricacies of RFx management, exploring best practices, technology integration, and how these processes can be leveraged to drive strategic sourcing success.

Key Benefits of RFx for Manufacturing Sector

RFx provides a number of unique benefits specific to the manufacturing sector. It encourages better supplier competition by establishing a transparent set of rules of the game for all, resulting in more efficient negotiations.

Competitive bidding helps manufacturers save money. RFx gives them the ability to compare apples to apples and identify the most cost-effective proposals.

Besides, by including compliance checks within vendor evaluations, the process helps organizations take greater control over adherence to industry regulations and standards. A manufacturer looking to source materials for a large, new infrastructure project might use RFx to handle supplier certifications.

This strategy allows them to maintain their focus on staying within their budget.

Types of RFx Documents

|

Document Type |

Purpose |

Best Context |

|---|---|---|

|

Collects detailed supplier proposals for specific projects |

Complex projects with defined requirements |

|

|

Gathers price quotes to compare costs for specific goods or services |

Standardized products or services |

|

|

Explores vendor capabilities and gathers preliminary information |

Early stages of supplier selection |

With ProQsmart’s AI-driven solutions including e-tenders, supplier monitoring, and workflow capabilities, RFX software management becomes more compliant and cost-efficient.

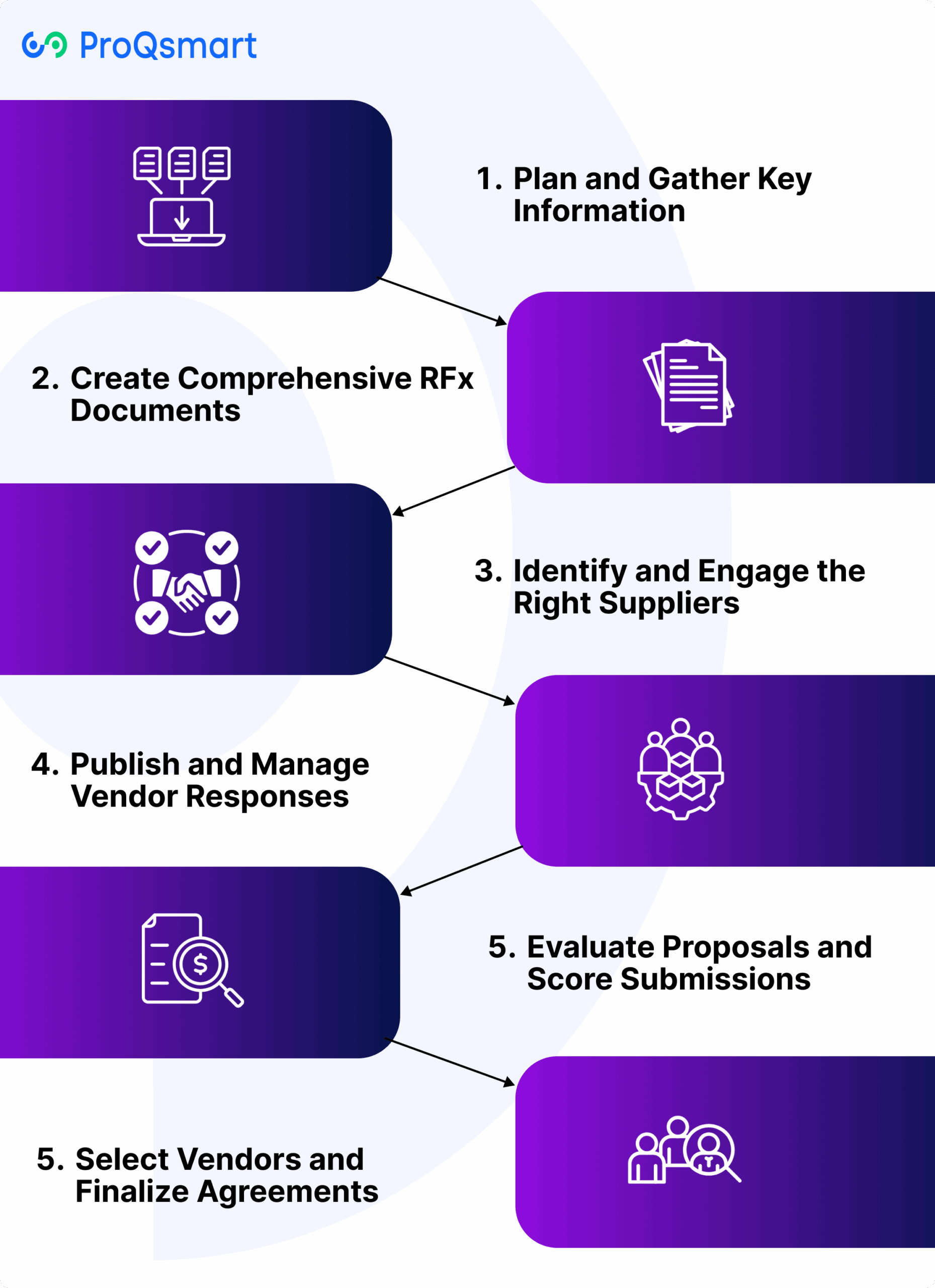

Steps to Master RFx Process

Mastering the RFx (Request for x) process is key to realizing the promised procurement efficiencies and moving manufacturing toward more strategic objectives. Utilizing rfx software facilitates a clear, collaborative process that leads to the best results. Below, we outline the main steps to help you master the RFx process.

1. Plan and Gather Key Information

Winning RFx starts with careful preparation. Begin by outlining important specifics like procurement goals, project deadlines, and budget limitations. Stakeholder input is crucial to defining procurement requirements—bring in internal teams to set expectations that align with organizational priorities.

Establish a single repository of information for all related data. This method makes it easier for users to access information and minimizes mistakes throughout the workflow. A collaborative tool such as ProQsmart can simplify this step, automate workflows, and help provide accurate data.

2. Create Comprehensive RFx Documents

An RFx document should be unambiguous, detailed and thorough. Make sure to include work to be performed, criteria by which you will evaluate proposals and instructions for submission. When your RFx is clear, you avoid unnecessary confusion and you motivate quality responses.

Using templates or platforms such as ProQsmart’s e-tendering function makes RFx document management easier while maintaining consistency and adherence to guidelines.

3. Identify and Engage the Right Suppliers

Identifying the best suppliers involves a tactical sourcing process. Evaluate vendors against your experience, capacity, and alignment with your needs. When engagement happens early, it allows everyone to better understand each other’s needs, goals, and priorities.

Foster relationships by communicating openly and using technology, such as ProQsmart, that tracks supplier performance and automates the pre-qualification process.

4. Publish and Manage Vendor Responses

Publishing RFx documents, including rfp questions and compliance challenges, means establishing firm submission deadlines and guidelines. ProQsmart’s real-time tracking enhances transparency while organizing all vendor responses for seamless management.

5. Evaluate Proposals and Score Submissions

Provide clear, fair scoring criteria to all bidders so proposals can be evaluated accordingly. Incorporate cross-functional teams to bring in a variety of perspectives. These scoring tools, integrated into the rfx software ProQsmart, offer an objective holistic picture, enabling procurement to make a data-driven selection that is trustworthy.

6. Select Vendors and Finalize Agreements

The vendor selection process culminates in agreeing upon terms and signing contracts, ensuring compliance with contractual requirements. ProQsmart serves as a friendly platform that connects procurement to budgets and effectively monitors improvement over time.

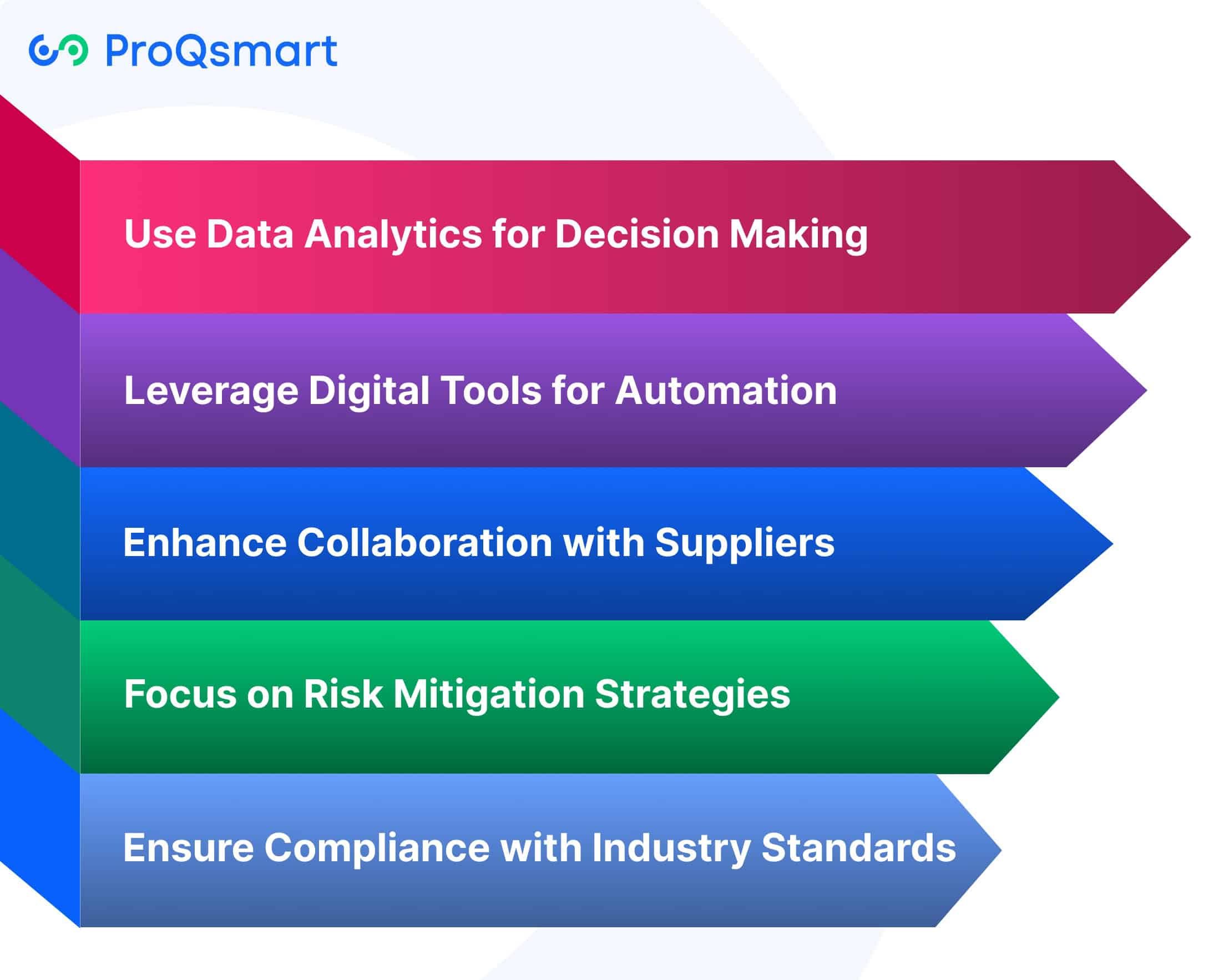

Best Practices for Effective RFx Management in Manufacturing

Ultimately, effective RFx management, particularly through the use of rfx software, serves as a foundation for successful procurement in the manufacturing sector. With a more structured approach and modern tools, organizations can drive clarity, efficiency, and improved supplier relationships.

Use Data Analytics for Decision Making

Data analytics revolutionizes procurement through a lens of actionable insights.

Use historical procurement data. Analyzing past procurement data will help you identify patterns, such as supplier performance trends or pricing fluctuations that allow you to make informed decisions. Taking a look back at previous RFx cycles can further shine a light on favored suppliers that always deliver on time and to spec.

Integrating analytics with RFx platforms allows procurement teams to evaluate responses against predefined metrics, ensuring decisions align with organizational goals.

Leverage Digital Tools for Automation

By automating time-consuming tasks, digital tools simplify the procurement process, eliminating the potential for manual errors while speeding up workflows.

Solutions like ProQsmart, for example, can help to centralize all RFx communications, automate document management processes, and streamline e-tendering. ProQsmart improves efficiency and transparency, informing procurement teams with real-time tracking capabilities, supplier performance monitoring and more.

Thus, this enables them to change the focus of their teams from administrivia to more strategic priorities. Popular software provides analytics dashboards, enabling data-driven decision-making and increased transparency.

Enhance Collaboration with Suppliers

Collaboration builds trust and enduring relationships. Having crystal clear communication, backed by RFx management software, helps make sure suppliers get what they need, when they need it.

Creating feedback loops with every RFx cycle helps create a system of continuous improvement. Through initiatives like regular performance reviews, you can further stay ahead of issues and focus on common goals to create outcomes that benefit both parties.

Focus on Risk Mitigation Strategies

Mitigation starts with rigorous vendor vetting, including an evaluation of their financial health, reputation, and regulatory or compliance history.

Validating supplier information, as included in RFP responses, with external third-party intelligence helps to minimize risk. Having all documentation centralized helps with auditing, ensuring transparency at every step of the procurement.

Ensure Compliance with Industry Standards

Compliance is the backbone of ethical and legal procurement. RFx documents need to be consistent with regulatory requirements such as OSHA regulations for manufacturing.

ProQsmart’s compliance features make this a breeze, automating documentation and creating auditable sourcing data to lower risks of non-compliance.

Future Trends in RFx for Manufacturing

From automation to AI, the RFx process is changing quickly to address increasing pressures and expectations for efficiency, innovation, and sustainability within manufacturing. With rapid technological development and a changing landscape of procurement priorities, organizations need to evolve with the times to remain competitive.

Here, we look at some of the biggest trends influencing the future of RFx and what they mean for the manufacturing industry.

Role of Artificial Intelligence in RFx

Artificial Intelligence (AI) is revolutionizing RFx processes by automating repetitive tasks and enhancing the accuracy of decision-making. AI-powered tools can help procurement teams analyze huge volumes of supplier data and quickly identify potential risks. Additionally, they help connect need with the best-fit vendors, significantly streamlining supplier selection.

Platforms such as ProQsmart use AI to track supplier performance. They offer real-time collaboration features that make building better relationships easy. AI also enables predictive capabilities, which streamline workflows by evaluating historical data to anticipate procurement needs.

For instance, AI-driven RFx tools, predicted to be adopted by 70% of procurement teams, reduce manual errors and accelerate document management. ProQsmart’s automation for subcontractor management and capital expenditure sourcing exemplifies these advancements.

Shift Towards Sustainable Sourcing Practices

Sustainability is quickly becoming a central focus of RFx processes. It is no secret that manufacturers are under increasing pressure to consider environmental and ethical factors when sourcing suppliers. Giving consideration to sustainability criteria within the RFx documentation process will help hold your organization accountable and create long-term value.

For instance, making sure an RFx requires energy-efficient materials or guaranteeing ethical labor practices can connect procurement to corporate responsibility objectives. With Future Trends in RFx for Manufacturing, ProQsmart connects procurement to budget-driven strategies, making these value-adding initiatives easier and compliant.

Increasing Use of Predictive Analytics

Predictive analytics gives procurement teams the ability to make data-driven decisions through the ability to forecast trends and analyze supplier performance. Similarly, smart real-time pricing models interconnected with IoT allow for real-time price adjustments, guaranteeing the most competitive sourcing.

Using centralized data, such as ProQsmart’s tracking capabilities, builds visibility and trust in the procurement process. This encourages more strategic, data-driven sourcing and ultimately fosters greater innovation and efficiency.

Leveraging Technology for RFx Efficiency: ProQsmart

ProQsmart is an AI-driven procurement platform that revolutionizes RFx (Request for X) processes, including the management of vendor questionnaires. It does this by utilizing sophisticated AI-powered automation, data analytics, and collaboration tools. ProQsmart enables procurement teams to focus on more than the status quo, enhancing their procurement processes and boosting efficiency across their enterprise.

This change allows teams to concentrate on strategic decision-making, thereby increasing value. What makes ProQsmart unique are its advanced automation features that streamline RFx workflows, eliminating much of the tedium associated with manual processes.

For instance, the platform automates file management, ensuring that all sourcing documents are stored in one easy-to-access location. This method not only saves time and increases transparency but also ensures regulatory compliance, as every part of the RFx process is auditable.

ProQsmart enables scoring thresholds for vendor responses, allowing your team to easily score and evaluate supplier proposals. With real-time insights, you can make smarter decisions. That way, you can easily select the most qualified suppliers—by performance, cost, and compliance standards.

ProQsmart helps you get more from your suppliers. ProQsmart doesn’t just manage your workflows more efficiently. Its tools encourage clear and consistent communication with vendors, building trust and alignment throughout the RFx process.

Real-time tracking, budget alignment, and supplier performance monitoring are just a few of the key features that keep everyone informed and working together. ProQsmart’s unique approach of combining automation with strategic sourcing tactics is what makes it essential for today’s procurement teams.

Conclusion

In conclusion, true mastery of RFx in manufacturing extends beyond merely releasing requests; it involves fostering stronger supplier relationships, reducing expenses, and maintaining agility in response to changing market conditions. By following detailed steps and best practices, organizations can ensure that their RFx process is effective and runs smoothly. The integration of technology, such as ProQsmart, accelerates this process, making it more accurate and efficient, allowing safety teams to prioritize their core responsibilities.

The future of RFx will be characterized by increased automation and the use of smarter tools. Understanding current trends and anticipating the capabilities of new technologies will be crucial for companies seeking to remain competitive. By adopting a smart approach to RFx, organizations can develop more strategic procurement strategies that drive economic growth.

Ready to take control of your RFx process and position your organization for success? Book a demo with ProQsmart today to discover how their innovative solutions can streamline your RFx workflows, enhance supplier engagement, and empower your team to make better, more strategic sourcing decisions.