Selecting the right sourcing strategy is essential for effective procurement. Two primary approaches—

Multiple sourcing

These offer distinct advantages and challenges that can significantly impact an organization’s efficiency and cost-effectiveness.

Single sourcing involves relying on one supplier for specific goods or services, which can streamline processes and foster strong relationships.

On the other hand, multiple sourcing engages several suppliers, providing flexibility and reducing risk.

Understanding these strategies is crucial for procurement professionals seeking to optimize their operations.

This article will explore the key differences between single sourcing and multiple sourcing, examining their benefits, drawbacks, and the factors that influence the choice of strategy. By evaluating these approaches, organizations can make informed decisions that align with their goals and enhance their overall procurement effectiveness.

What is Single Sourcing?

Single sourcing is a strategic sourcing process where a company selects one supplier to provide a specific product or service.

Pros | Cons |

Stronger Supplier Relationships: Building a close partnership can lead to better collaboration and trust. | Supply Chain Vulnerability: Relying on one supplier increases the risk of disruptions due to delays or shortages. |

Better Pricing: Consolidating purchases often allows for bulk pricing and cost savings. | Limited Innovation: Dependence on a single supplier may limit access to new technologies or materials. |

Improved Quality: A focused relationship can enhance quality control and product consistency. | Reduced Flexibility: Adapting to market changes may be more difficult if the supplier cannot keep pace. |

Streamlined Procurement Processes: Fewer contracts and invoices simplify administrative tasks. | Higher Risk of Supplier Failure: If the sole supplier encounters financial or operational issues, it can severely impact the business. |

Negotiation Advantages: Companies can negotiate favorable terms, including customized service agreements. |

|

This includes evaluating the supplier’s performance history, financial stability, and ability to scale production while maintaining quality. By ensuring that their chosen supplier is reliable and capable, businesses can maximize the benefits of a successful sourcing strategy while minimizing potential drawbacks.

What is Multiple Sourcing?

Multiple sourcing is a strategic sourcing approach where companies engage several suppliers for the same product or service. This procurement strategy reduces risk by ensuring that no single supplier has complete control over the supply chain. For instance, in the construction industry, a company might utilize procurement activities to source materials like concrete or steel from multiple vendors. This flexibility protects against supply disruptions; if one supplier experiences delays, others can step in to fulfill orders, keeping projects on schedule.

Pros | Cons |

Risk Mitigation: Having alternative suppliers ensures continuity in operations during disruptions, such as natural disasters affecting a supplier’s capabilities. | Increased Management Complexity: Managing multiple suppliers requires more effort and resources, which can lead to higher overhead costs. |

Better Negotiation Leverage: With several suppliers competing for contracts, companies can negotiate better prices and terms. | Quality Consistency Challenges: Ensuring consistent quality and delivery schedules among various suppliers necessitates careful oversight. |

Flexibility in Supply Chain: Multiple sourcing provides flexibility to adapt to changing market conditions and demands. | Relationship Management Needs: Building strong relationships with all suppliers is crucial for success, requiring time and effort to foster collaboration and mutual understanding. |

Diverse Supplier Base: A varied supplier base can lead to innovation and access to a wider range of materials and technologies. | Potential for Increased Overhead: The administrative burden of managing multiple contracts and communications can increase operational costs. |

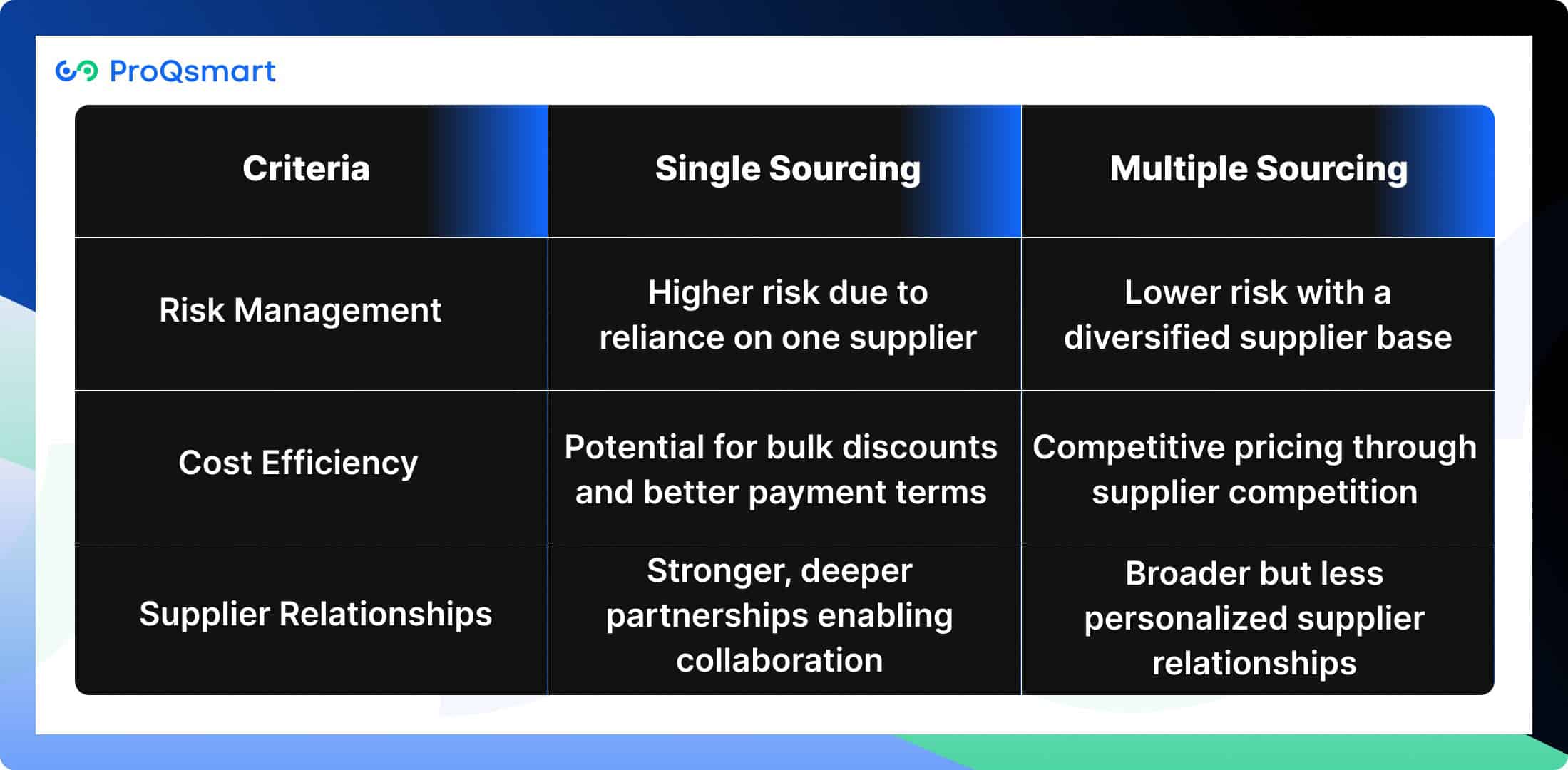

Key Differences between Single Sourcing and Multiple Sourcing

Single sourcing and multiple sourcing are two distinct procurement strategies, each with its own benefits and challenges. Below is a summary of the key differences between the two approaches:

Criteria | Single Sourcing | Multiple Sourcing |

Risk Management | Higher risk due to reliance on one supplier | Lower risk with a diversified supplier base |

Cost Efficiency | Potential for bulk discounts and better payment terms | Competitive pricing through supplier competition |

Supplier Relationships | Stronger, deeper partnerships enabling collaboration | Broader but less personalized supplier relationships |

Single sourcing fosters stronger partnerships by requiring companies to build trust and collaboration with a single supplier. This approach is particularly effective when quality and customization are critical. For example, in industries where specific materials or components are essential, having a dedicated supplier can streamline communication and enhance production efficiency.

On the other hand, multiple sourcing encourages competitive pricing by leveraging competition among suppliers. This strategy enhances supply chain agility, allowing companies to adapt quickly to changes. For instance, in the manufacturing sector, having multiple suppliers for critical components can prevent production delays caused by disruptions from any single source. While multiple sourcing reduces the chances of interruptions, it also demands greater oversight.

Managing several suppliers requires more resources to monitor performance and ensure compliance with quality standards. Despite this complexity, many organizations are increasingly adopting multi-sourcing strategies to build resilience in their supply chains. Ultimately, companies must carefully consider their individual goals when deciding between these two strategies. Single sourcing may be ideal for speed and efficiency, while multiple sourcing supports flexibility and risk management in dynamic market conditions.

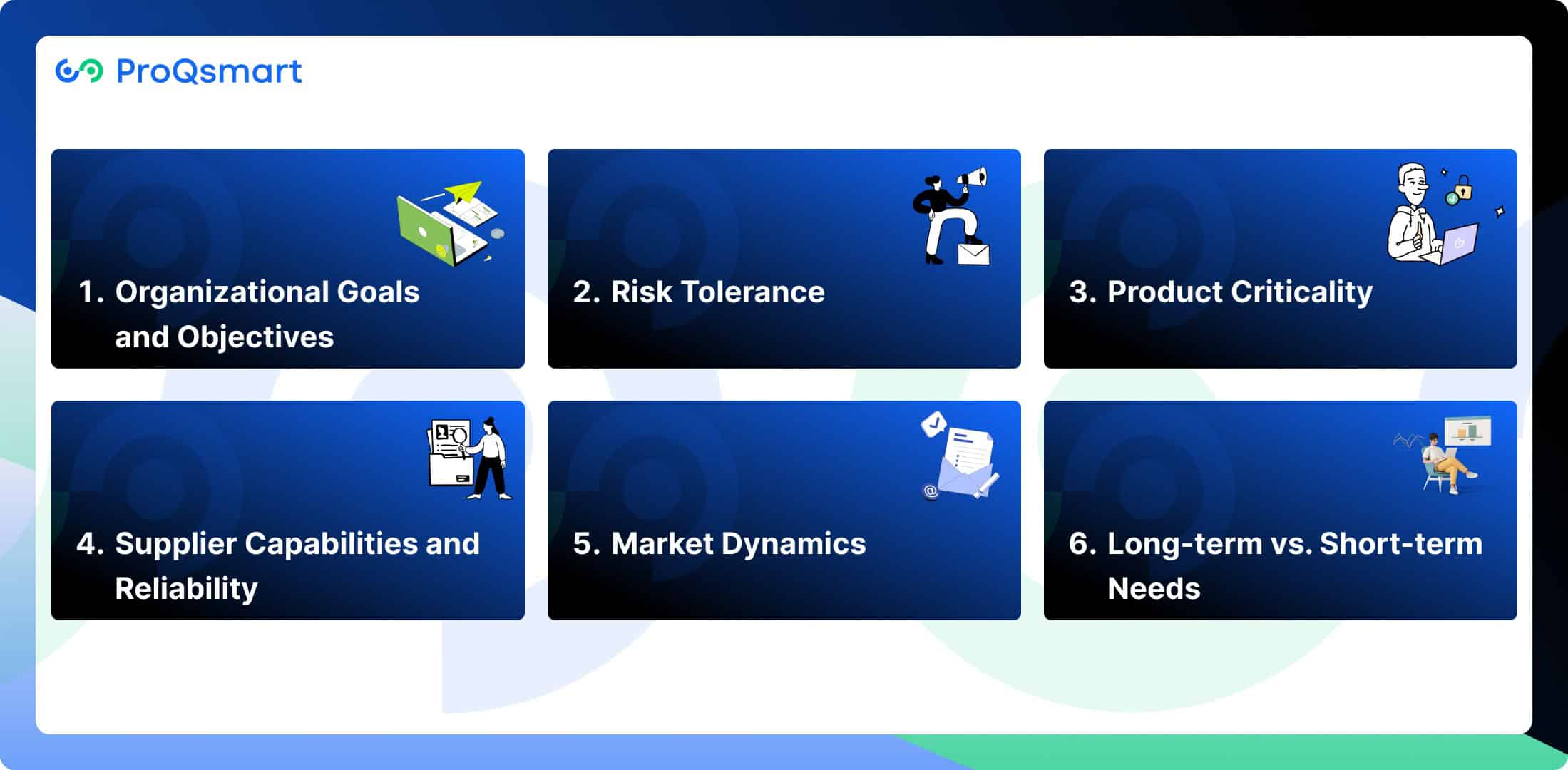

Factors to Consider When Choosing a Sourcing Strategy

Organizational Goals and Objectives

Ultimately, sourcing strategies achieve the best results when they are strategically aligned with an organization’s broader goals. Whether the goal is to save taxpayer dollars, enhance quality, or promote innovation, these goals should be at the forefront of every sourcing decision.

For example, a manufacturing company focused on reducing production costs would prioritize suppliers that offer the most cost-effective solutions. On the other hand, an innovative manufacturing firm would seek collaborators recognized for their pioneering approaches and advanced technologies. Having clear objectives in sourcing makes decision-making easier and helps ensure that any procurement efforts maximize the potential for long-term success in the manufacturing sector.

It’s important to regularly revisit these goals, though, as business priorities can change quickly. Involving stakeholders from all relevant departments, from operations to finance, ensures that the sourcing process meets the larger organizational goals.

Risk Tolerance

Risk tolerance plays a pivotal role in shaping sourcing strategies. Organizations with low risk tolerance may opt for single sourcing to maintain supply chain stability, especially for critical products.

Companies willing to navigate higher risks might explore multi-sourcing or global suppliers to drive cost advantages. Conducting thorough risk assessments is crucial. For instance, evaluating potential disruptions, like geopolitical tensions or supplier insolvencies, helps businesses prepare contingency plans.

Including diversification in supplier bases can mitigate risks while ensuring a steady supply chain.

Product Criticality

The criticality of a product has an enormous impact on sourcing decisions. High-criticality products, like highly specialized components used in healthcare or aerospace, may need single sourcing to ensure that the exact same product is delivered every time.

The more non-critical items provide room for flexibility, giving businesses the ability to pursue cost-saving opportunities with multi-sourcing. By continually evaluating the relative importance of products, you can keep your sourcing strategies flexible and responsive.

Using Saas solutions like ProQsmart can help prioritize products based on their impact on operations and supply risk, ensuring an optimal allocation of resources.

Supplier Capabilities and Reliability

Supplier capability evaluation is the bedrock of successful sourcing. Choosing the right suppliers ensures a smoother operation while minimizing risk and fostering productive, long-term partnerships.

Demanding to see evidence of a supplier’s past performance, ability to scale production, and their financial strength gives a better sense of a supplier’s long-term potential. For example, a supplier with a track record of on-time delivery and a strong ability to scale works best for companies in the interior fit-out industry looking to grow.

Ongoing supplier performance reviews ensure quality is always high, and a supplier always matches your sourcing strategy.

Market Dynamics

Market dynamics significantly influence sourcing strategies, and understanding these conditions is essential for effective procurement. Factors such as demand variability, supply constraints, and competitive pressures dictate which suppliers companies choose to work with.

By monitoring macroeconomic trends and geopolitical events, organizations can adapt their sourcing strategies to remain competitive. For instance, focusing on emerging markets can provide advantages in sourcing and supply chain management.

Agility is crucial in today’s market. Engaging a diverse range of suppliers helps companies build resilience against unexpected changes, ensuring smooth operations even when disruptions occur. This strategic flexibility allows businesses to respond effectively to shifting market conditions and maintain a steady flow of goods and services.

Long-term vs. Short-term Needs

Finding the right balance between long-term and short-term requirements is critical to successful sourcing. While long-term strategies encourage dependable relationships and consistent supply chains, short-term strategies meet urgent needs.

A balanced approach between predictable, lasting partnerships and nimble, adaptable partners that can pivot with changing needs will unlock the most collective efficiency. Through regular reviews, have these strategies evolve in accordance with organizational goals and market conditions.

The Role of Technology and Tools in Enhancing Sourcing Decision-Making

In the modern procurement landscape, technology and tools play a pivotal role in supporting the strategic sourcing process. By automating procurement activities, providing real-time sourcing data, and enhancing supplier management, these solutions empower organizations to make informed choices that align with their strategic goals.

Automation of Procurement Processes

One of the primary benefits of procurement technology is the automation of various tasks involved in the strategic sourcing process. For instance, automating workflows for supplier onboarding, order processing, and invoice management reduces manual intervention. As a result, organizations can minimize errors and accelerate the procurement lifecycle, allowing teams to focus on more strategic sourcing activities.

Access to Real-Time Data and Analytics

Moreover, technology enables procurement professionals to access real-time data and analytics on spending patterns, supplier performance, and market trends. This information is crucial for making informed strategic sourcing decisions. With comprehensive procurement software and advanced analytics tools, organizations can identify cost-saving opportunities and assess supplier reliability effectively.

Enhanced Supplier Evaluation

In addition, strategic sourcing processes facilitate comprehensive evaluations of potential suppliers. These systems allow organizations to track performance metrics, assess financial stability, and ensure compliance with industry standards. By having a structured approach to supplier evaluation, companies can build stronger relationships with reliable suppliers.

Improved Collaboration and Communication

Furthermore, digital platforms enhance collaboration between procurement teams and vendors. For example, ProQsmart is a comprehensive procurement solution that centralizes communications, facilitating the management of contracts and sourcing activities. This leads to better alignment on expectations and fosters stronger supplier partnerships.

Streamlined Decision-Making

Finally, e-sourcing solutions simplify the bidding process by integrating all supplier communications into one platform. This strategic sourcing process allows procurement teams to easily compare bids, evaluate proposals efficiently, and select the best suppliers based on objective criteria. As a result, streamlined decision-making processes lead to faster approvals and more effective sourcing outcomes.

For all these capabilities, you can rely on ProQsmart. This comprehensive procurement software offers a range of features designed to enhance your strategic sourcing efforts. Additionally, it includes robust RFx management, allowing you to create and manage Requests for Information (RFIs), Requests for Proposals (RFPs), and Requests for Quotations (RFQs) efficiently. Notably, ProQsmart’s e-sourcing functionality simplifies the entire procurement process by centralizing supplier communications and document management, enabling procurement teams to efficiently select the right suppliers.

With ProQsmart, you gain access to advanced tools such as automated bid management, real-time collaboration features, and detailed analytics. These functionalities not only save time but also enhance the overall effectiveness of your strategic sourcing solutions.

Conclusion

Both single sourcing and multiple sourcing approaches offer distinct advantages based on your business priorities, supplier dynamics, and risk appetite. It is essential to consider elements such as cost, supply chain reliability, and market effects while balancing these factors. This holistic approach is key to making informed, strategic decisions that deliver maximum value.

Modern tools, particularly e-sourcing software, make these decisions easier. They provide access to real-time data, simplify the supplier evaluation process, and increase overall transparency. In an unforgiving and rapidly evolving market, leveraging these technologies is imperative to remain competitive. As you develop your sourcing strategy, keep your long-term business goals in mind. Stay flexible, explore new technology solutions, and continue nurturing collaborative relationships with suppliers. Remember, procurement success begins with better sourcing decisions.

To take the next step in optimizing your sourcing strategy, consider using ProQsmart. With its robust features for e-sourcing and supplier management, ProQsmart can help streamline your procurement processes and enhance decision-making. Book a demo today to see how ProQsmart can transform your sourcing efforts!

FAQs

What is single sourcing in procurement?

Single sourcing occurs when a business utilizes one supplier for all its sourcing needs for a certain product or service. This approach can save time and foster strong supplier relationships, consistency, and ultimately, cost savings. However, it introduces supply chain risks related to the supplier’s ability to withstand disruptions.

What is multiple sourcing in procurement?

Multi-sourcing is a strategic sourcing model that involves utilizing several suppliers for a given product or service. This strategic sourcing approach reduces dependency on a sole-source vendor and enhances competition, ultimately strengthening supply chain operations while potentially introducing added complexity and administrative burden.

What are the key differences between single and multiple sourcing?

Single sourcing focuses on one supplier, which can simplify procurement activities and foster deeper supplier partnerships. In contrast, multiple sourcing involves engaging various vendors, offering flexibility and reduced supply chain risks. The best approach depends on each business’s unique needs, market conditions, and strategic sourcing objectives.

How do I choose between single and multiple sourcing?

Consider all issues such as supply chain risks, cost efficiency, product criticality, and supplier reliability. Identify your organizational priorities and balance the advantages of a strategic sourcing process with the value of adaptability. Comprehensive procurement software can help fuel this decision-making process.

What tools can help with sourcing decisions?

E-sourcing software and comprehensive procurement platforms like ProQsmart streamline procurement activities, enhancing supplier selection, cost analysis, and contract management. ProQsmart empowers procurement teams to make informed decisions and fosters strong supplier relationships.

What is e-sourcing software?

E-sourcing software streamlines and automates the entire procurement process, enhancing procurement activities from supplier evaluation and selection to contract award. This comprehensive procurement software improves transparency, shortens procurement cycle times, and enables businesses to make informed, data-driven sourcing decisions.

Why should I brand sourcing strategies with ProQsmart?

ProQsmart provides innovative e-sourcing solutions that enhance procurement activities and efficiency. With features like automated bid management, advanced analytics, and streamlined RFQ processes, companies can implement a successful sourcing strategy and improve supplier evaluations.