What Is Sole Sourcing?

Sole sourcing is a specific procurement strategy where an organization opts for a sole source purchase to meet its unique and specialized needs. This approach is particularly useful when only one vendor has the necessary expertise, experience, or proprietary technology to deliver what is required. By partnering exclusively with a single supplier, organizations can simplify their procurement processes, shorten lead times, and build strong, collaborative relationships, ultimately enhancing their supplier relations.

One of the key benefits of sole sourcing is the ability to set strict quality standards and enhance transparency throughout the supply chain. This method works exceptionally well when companies require specialized products or services that aren’t available from multiple sources. However, it’s crucial to approach a sole source situation carefully to avoid risks like favoritism and to ensure compliance with procurement policies.

When executed effectively, sole sourcing can improve operational efficiency and support long-term strategic goals across various industries, including manufacturing and construction. Understanding the criteria for this procurement method is essential for organizations looking to leverage its benefits while maintaining accountability and maximizing value.

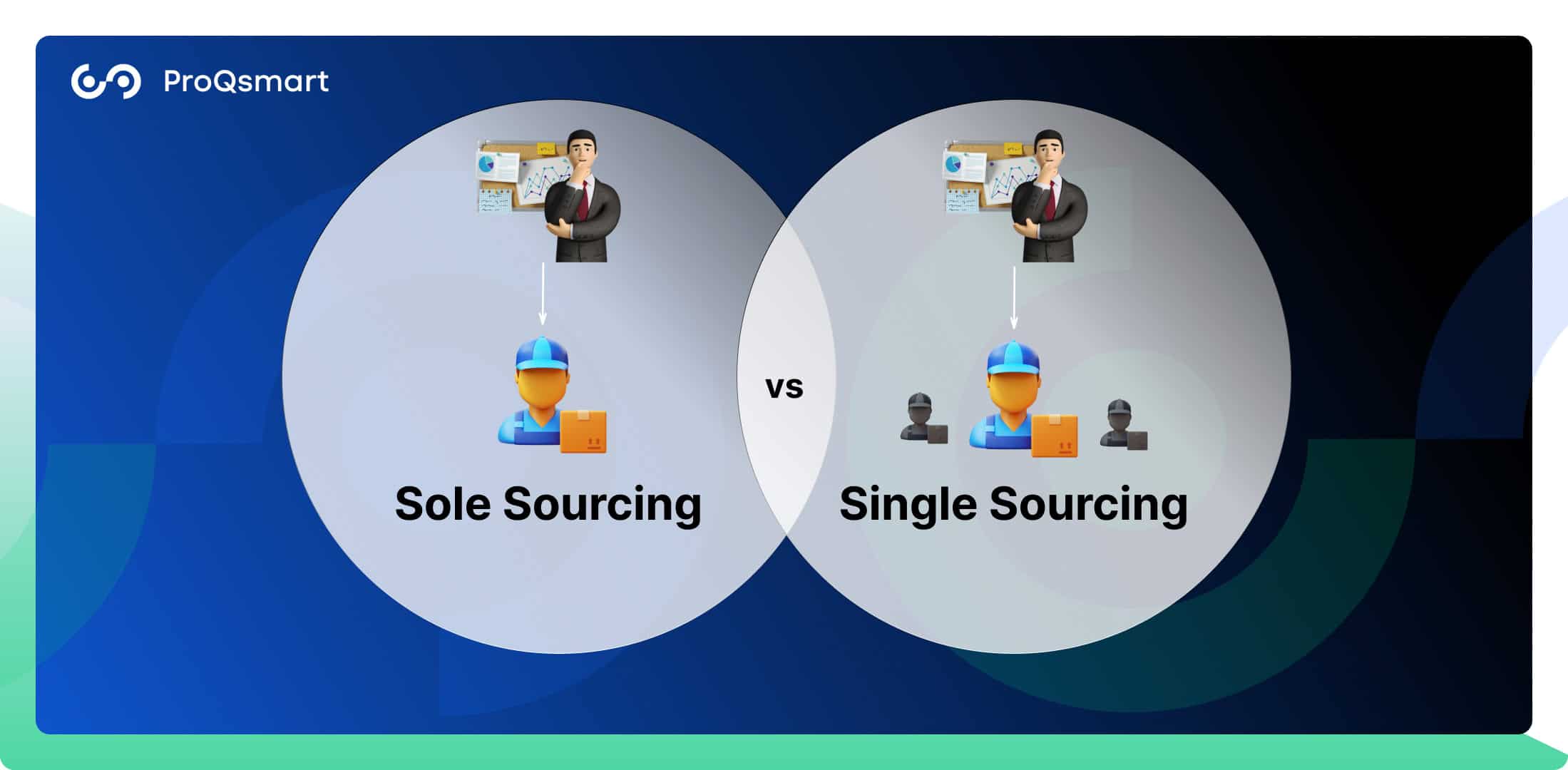

Differences Between Sole and Single Sourcing

Aspect | Sole Sourcing | Single Sourcing |

Definition | Dependence on a single supplier with no alternatives available. | Choosing one supplier from several options. |

Supplier Power | Supplier has the power to set terms and conditions. | Company has the power to choose based on desired terms. |

Cost Implications | Often leads to inflated prices due to lack of competition. | Allows for effective price negotiations with multiple suppliers. |

Supplier Relationships | Can foster deeper relationships with the sole supplier. | Builds relationships, but may not be as deep as sole sourcing. |

Impact on Innovation | 70% of procurement professionals see it as a barrier to innovation. | Encourages competition, which can drive innovation. |

Usage Context | Used in unique situations where no other options exist. | Used when a company prefers one supplier among many. |

Impact of Sole Sourcing in Procurement

Sole sourcing can significantly influence procurement practices, particularly in the construction and manufacturing industries, highlighting the advantages and disadvantages of this sourcing strategy.

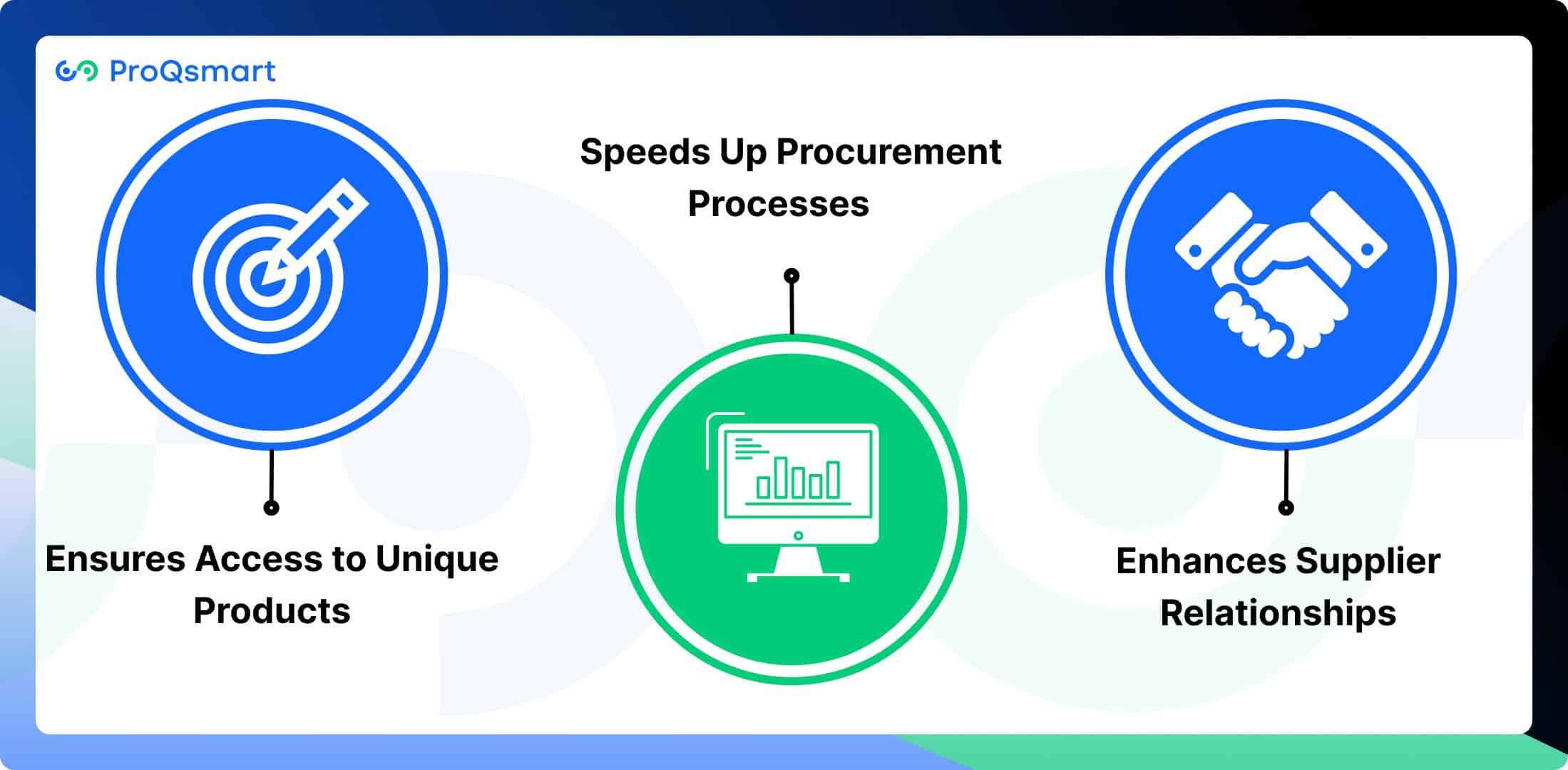

Ensures Access to Unique Products

Sole sourcing is essential for obtaining specialized goods or services that are not available through competitive bidding. For example, in construction, certain materials like specialized concrete mixes or unique structural components may only be produced by a limited number of suppliers. By partnering with a sole supplier, companies can access these critical products, which helps them meet specific design and regulatory requirements.

Establishing strong relationships with these suppliers is vital. For instance, a construction firm might rely on a sole source for patented building materials essential for a project. Building trust and maintaining open communication with the supplier ensures reliable access to these important materials while reducing the risk of supply chain disruptions.

Speeds Up Procurement Processes

Working with a single supplier simplifies the procurement process. Companies can avoid lengthy sourcing and selection procedures, leading to faster decision-making. This efficiency allows procurement teams to focus on other important tasks.

In urgent situations, such as needing materials quickly for a construction project due to unexpected delays, sole sourcing enables immediate procurement of necessary items. For example, if an interior fit-out company has already identified a specific supplier for high-quality flooring materials needed for a project, they can quickly obtain those items without delays caused by comparing multiple vendors. This streamlined approach allows them to maintain project timelines and ensure that the installation process proceeds smoothly.

Enhances Supplier Relationships

Consistently working with one supplier fosters stronger partnerships over time. These long-term relationships often lead to improved service levels as suppliers become more familiar with the organization’s needs. For instance, when a manufacturing company sources parts from one supplier, they may receive tailored support that includes optimized delivery schedules and customized solutions.

Challenges of Sole Sourcing

While sole sourcing offers several advantages, it also presents significant challenges that procurement specialists must navigate carefully in a sole source situation. Recognizing these challenges is essential for maintaining operational stability, controlling costs, and ensuring quality products.

1. Risks of Supplier Dependency

Relying on a single supplier for critical goods or services can create substantial risks. This dependency makes organizations vulnerable to disruptions caused by supplier issues, such as financial problems or production delays. For example, if a key supplier faces a crisis, it could halt production and affect the entire supply chain.

To reduce these risks, it is important to maintain one to three alternative suppliers. This strategy ensures that there are backup options available if the sole supplier cannot deliver. Additionally, organizations should develop contingency plans and conduct regular assessments of supplier risks to prepare for potential disruptions.

2. Lack of Competitive Pricing

Another challenge of sole sourcing is the potential for higher costs due to reduced competition. Without multiple suppliers bidding for business, prices may rise as the sole supplier has more control over pricing. This can lead to increased expenses for the organization.

To address this issue, conducting thorough price analysis is crucial, even when working with a sole supplier. Organizations should regularly negotiate prices and consider external benchmarks to ensure they are getting fair rates. This practice helps maintain cost control and prevents unnecessary spending.

3. Potential Quality Control Issues

Quality control can be a significant concern with sole sourcing. Relying on one supplier increases the risk of quality failures, which can lead to customer dissatisfaction and operational problems. If the sole supplier does not meet quality standards, it can have serious repercussions for the organization.

To mitigate these risks, companies should establish clear quality standards and monitor compliance closely. Having contingency plans in place allows organizations to respond quickly if quality issues arise. Additionally, creating detailed contracts that outline expectations can help ensure that quality remains a priority throughout the partnership.

Best Practices for Sole Sourcing

Here are some key best practices to ensure that sole sourcing works:

1. Conduct Thorough Supplier Assessments

Before committing to a sole supplier, it is critical to evaluate their capabilities comprehensively. This includes analyzing their production capacity, reliability, financial stability, and past performance.

Regular assessments should continue throughout the partnership to ensure they meet growing demands or adapt to market changes. By sharing your target prices and current cost structures, suppliers can better align with your needs while optimizing their operations. This transparency fosters trust and collaboration.

2. Develop Strong Contractual Agreements

Well defined contracts are the foundation of an effective sole sourcing partnership. These contracts need to specify agreement on pricing models, lead times, service levels, and methods for resolution of conflict. Legal protections, including liability clauses, offer protection to both parties in the event of unforeseen occurrences.

By building flexibility into contracts, we can leave room to pivot when a major economic shift or supply chain disruption occurs.

3. Regularly Monitor Supplier Performance

Performance monitoring, on a continual basis, keeps your suppliers on their toes and helps to guarantee ongoing quality. Setting defined KPIs such as on-time delivery, quality metrics, and cost-effectiveness helps set clear, measurable expectations.

Regular feedback conversations allow supervisors and interns to meet frequently and discuss any issues that arise in real time. Annual cost-benefit analyses after the pandemic will show where we can do better, making sure our long-term success is the real deal.

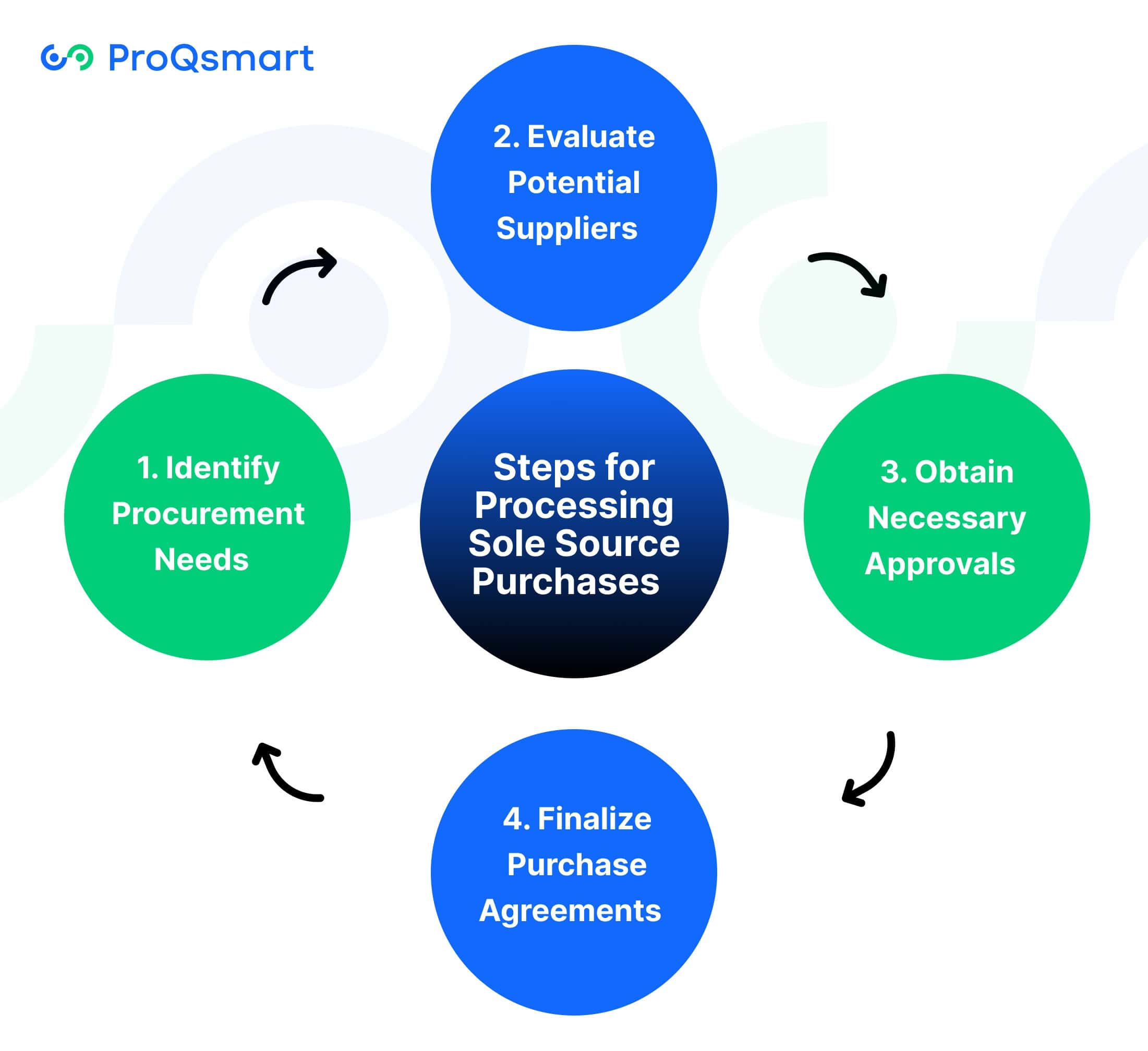

Steps for Processing Sole Source Purchases

1. Identify Procurement Needs

Identifying procurement needs is a crucial first step in the sole sourcing process. A clear definition of these needs ensures that purchases align with organizational priorities and eliminates ambiguity.

Engaging stakeholders early, particularly from key departments like operations and finance, is essential for identifying critical requirements such as delivery schedules and budget constraints. This collaboration aligns procurement decisions with broader company objectives, including sustainability goals and cost reduction initiatives.

Additionally, analyzing existing contracts and spending data can reveal gaps in the supply chain, leading to a more informed procurement strategy. By taking these steps, organizations can effectively define their procurement needs and ensure they support long-term goals.

2. Evaluate Potential Suppliers

When choosing to sole source, evaluating suppliers requires a different approach. Begin by assessing criteria such as reliability, the ability to meet quality standards, and overall market reputation. For instance, when procuring high-grade materials for construction, it is important to ensure that the supplier complies with relevant industry certifications.

Additionally, examining past performance is crucial. Reviewing case studies or client testimonials can provide valuable insights into a supplier’s history and reliability. Conducting thorough due diligence is not optional; it is essential to verify the supplier’s financial stability, operational capabilities, and legal eligibility.

From an accountability perspective, a robust vetting process minimizes risks and ensures that the selected supplier has the capacity to meet your requirements effectively. By taking these steps, organizations can make informed decisions that support successful procurement outcomes.

3. Obtain Necessary Approvals

Navigating the sole source approval process takes a lot of discipline, respect for internal procedures, and consideration of outside law. Start by developing documentation to justify the sole source decision, which could include a cost-benefit analysis or risk mitigation plan.

Use this as a powerful tool to present to your procurement committees or decision-makers for consideration! Timeliness is critical—any delay in approvals can throw a project’s schedule off or result in added expenses. Being diligent and organized makes this important step an easy one.

4. Finalize Purchase Agreements

A properly crafted contract lays the foundation for a positive supplier partnership. Specify gauge details such as prices, payment terms, and delivery dates. Written clarity protects both parties and makes it clear what they’re responsible for.

For instance, including details such as “must be delivered within 30 days” to prevent different interpretations. Developing mutual agreement on deliverables, timelines, and penalties for failure to comply fosters trust and accountability.

Future Trends in Sole Sourcing

1. Use of Technology Tools

Technology is becoming an essential component to help modernize and keep sole source purchases practices in check. Thanks to advanced procurement software, businesses today can stay on top of supplier relationship management like never before. For instance, solutions such as ProQsmart that provide automated workflows, like contract management tools, streamline redundant tasks, allowing teams to save precious time and avoid costly mistakes in their sourcing strategy.

ProQsmart’s supplier management solutions make it easy to keep procurement teams equipped with up-to-date records and track supplier performance effectively. Data analytics is completely revolutionizing how companies make sourcing decisions. By understanding historical trends, patterns in demand, and supplier capabilities, companies can develop a more informed set of options to choose from and reduce risk in a sole source situation.

For example, predictive analytics plays a crucial role in predicting disruptions, enabling businesses to take proactive measures to minimize risks. ProQsmart’s AI-driven insights are helping procurement teams quickly identify and narrow down potential suppliers based on their unique needs and performance metrics.

2. Focus on Sustainable Procurement Practices

Sustainability is quickly becoming a key pillar of procurement strategies, including the concept of sole source purchases. As more businesses aim to align their supply chains with environmental and social goals, ethical sourcing and supplier responsibility are increasingly important.

Today, organizations consider vendors not just for cost and quality but also for their adherence to sustainability criteria. This shift has compelled many firms to prioritize long-term relationships with sustainable suppliers, aligning their sourcing strategy with global sustainability goals.

3. Adapting to Global Supply Chain Changes

Recent changes in the global supply chain are significantly affecting sole sourcing practices. Companies are increasingly recognizing the importance of flexibility in their sourcing strategies. For instance, some organizations that rely heavily on a single supplier are now looking to diversify their sources to prevent potential bottlenecks.

Strengthening supplier resilience is essential during disruptions. Many companies are adopting dual or multi-sourcing strategies to avoid dependence on a single supplier. This approach not only helps maintain business continuity but also mitigates operational risks. By having multiple suppliers, organizations can ensure they have alternatives available if one supplier encounters issues.

Conclusion

Sole sourcing is a strategic procurement approach that can yield significant benefits, such as strengthened supplier relationships and timely access to critical goods and services. However, it also requires careful planning and thorough justification to mitigate potential risks. By engaging stakeholders, clearly defining procurement needs, and conducting diligent supplier evaluations, organizations can effectively navigate the complexities of sole sourcing.

As the global supply chain landscape continues to evolve, adapting to new trends and technologies will be essential for maintaining operational efficiency. When managed properly, sole sourcing can lead to enhanced value and improved performance for your organization.

To fully leverage the advantages of sole sourcing while minimizing risks, it is crucial to stay proactive in your procurement strategies. If you’re ready to transform your procurement process and explore how sole sourcing can benefit your organization, book a demo with ProQsmart today. Discover how we can help you streamline your procurement operations and achieve long-term success!