Procurement teams often face challenges in achieving consistent RFx evaluations due to varied metrics and fragmented processes across departments. Disparate scoring methods, inconsistent data collection, and lack of a unified tracking system can lead to misaligned supplier evaluations, delayed decisions, and missed opportunities for optimal vendor selection. These inconsistencies not only hinder transparency but also complicate compliance with audit requirements, increasing the risk of inefficiencies and errors. Without a standardized approach, ensuring fairness and accuracy in supplier performance tracking remains a persistent struggle for organizations managing complex RFx processes.

How Do Inconsistent Metrics Undermine the RFx Process?

Subjective Scoring

Subjective scoring introduces personal bias into vendor evaluations, as review committees may award points based on individual preferences or past experiences rather than objective standards. This lack of a unified scoring scale leads to inconsistent assessments, making it difficult to compare supplier capabilities fairly and increasing the risk of overlooking the most suitable vendor for the project. Inconsistent metrics not only undermine the integrity of the evaluation process but also result in missed opportunities for cost savings and operational improvements.

Implementing a standardized scoring system addresses these challenges by ensuring all suppliers are measured against explicit, transparent criteria. This approach reduces variance between evaluators, promotes fairness, and builds trust in the procurement process. By making scoring benchmarks public and consistent, organizations can more accurately track purchasing KPIs and drive better outcomes in supplier selection

Delayed Decisions

When teams rely on inconsistent metrics, the vendor selection process often becomes bogged down by prolonged debates over definitions, the relevance of criteria, and repeated analyses to reconcile differing standards. This inefficiency not only wastes valuable time but can also lead to internal friction, as team members struggle to reach consensus on which suppliers best meet project needs.

Timely, well-informed decisions are essential for staying competitive and maintaining positive supplier relationships. Delays caused by metric misalignment can disrupt project timelines, drive up costs, and ultimately harm the organization’s reputation in the marketplace.

Unreliable Data

When source data comes in varying forms, the output is difficult to rely on, complicating the procurement processes. With inconsistent data, it becomes hard to compare supplier performance or measure procurement ROI. Procurement teams require reliable metrics to inform their sourcing strategies. Data validation can aid in supplier management, while transparent data collection fosters strong supplier relationships, ensuring that procurement teams trust the information for informed sourcing decisions.

Increased Risk

|

Risk Area |

Impact of Inconsistent Metrics |

|---|---|

|

Vendor Selection |

Poor fit, higher costs, lower service quality |

|

Process Compliance |

Audit issues, regulatory penalties |

|

Data Quality |

Gaps in insight, faulty performance tracking |

|

Resource Efficiency |

Wasted time, duplicated effort |

Suboptimal vendor selection is common when teams rely on unreliable evaluations. Missed compliance checks and manual procurement processes expose organizations to risk. A risk management framework helps fill holes from inconsistent metrics, while improved supplier collaboration increases engagement. Complying with standards is the best way to minimize both compliance and business risk.

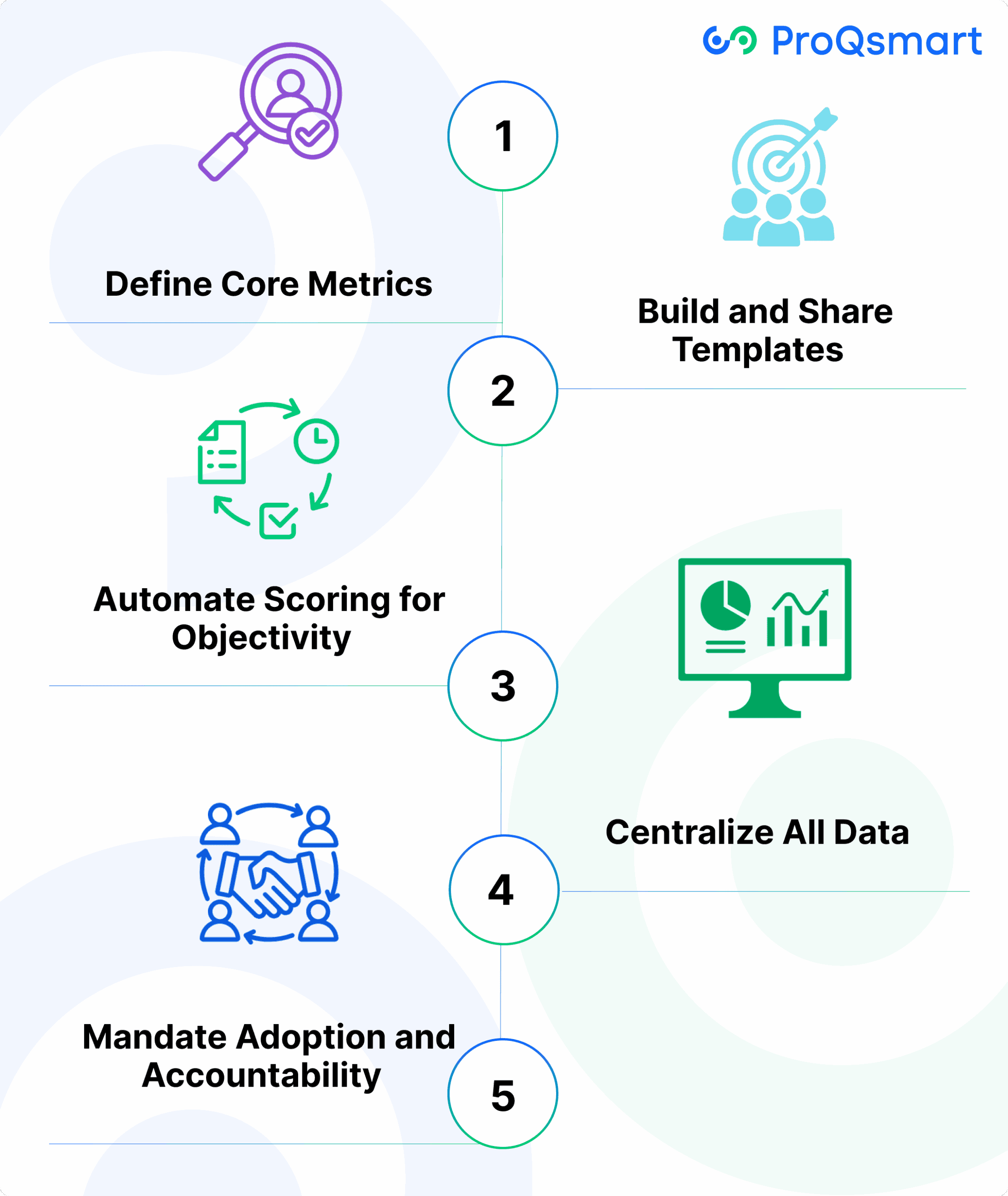

How to Standardize RFX Metrics?

Standardizing RFx metrics is about applying a transparent, reusable set of criteria and information to every sourcing initiative. This gets teams speaking a common language, working faster, and making smarter decisions.

1. Define Core Metrics

-

Start by identifying the metrics that truly drive your organization’s procurement success—think price, quality, lead times, or supplier sustainability scores.

-

Engage stakeholders from procurement, finance, and operations to select these metrics, ensuring both alignment and buy-in across the business.

-

Blend quantitative data (like price per unit) with qualitative factors (such as risk or supplier diversity), and commit to reviewing these metrics at least annually so they stay relevant as your market and strategies evolve.

2. Build and Share Templates

-

Create standardized RFx templates to ensure every team knows exactly what’s needed and to speed up supplier evaluation.

-

Templates help onboard new team members quickly and enable managers to spot missing information at a glance.

-

For unique projects, adapt templates as needed, but always keep core sections consistent—and store them centrally for easy team access.

3. Automate Scoring for Objectivity

-

Use procurement software to automate the scoring of vendor bids, reducing human error and eliminating bias.

-

Integrate your scoring tools with the broader procurement system to keep all data unified and actionable1.

-

As your business priorities shift—such as adding carbon footprint as a new focus—update scoring rules and weights to reflect what matters most.

4. Centralize All Data

-

Store RFx files, supplier profiles, and bid responses in a single, secure system to create one source of truth for your team.

-

Centralized data makes it easier to spot trends, compare bids, and keep records up to date.

-

Connect with other systems like ERP or supplier risk tools for a comprehensive view, and regularly audit your database to remove outdated or inaccurate information2.

5. Mandate Adoption and Accountability

-

Make it policy for all teams to use the same metrics and templates, with visible support from senior leadership to drive adoption.

-

Run workshops to ensure everyone knows how to use the new tools, and assign accountability for compliance—this keeps results consistent, fair, and reliable.

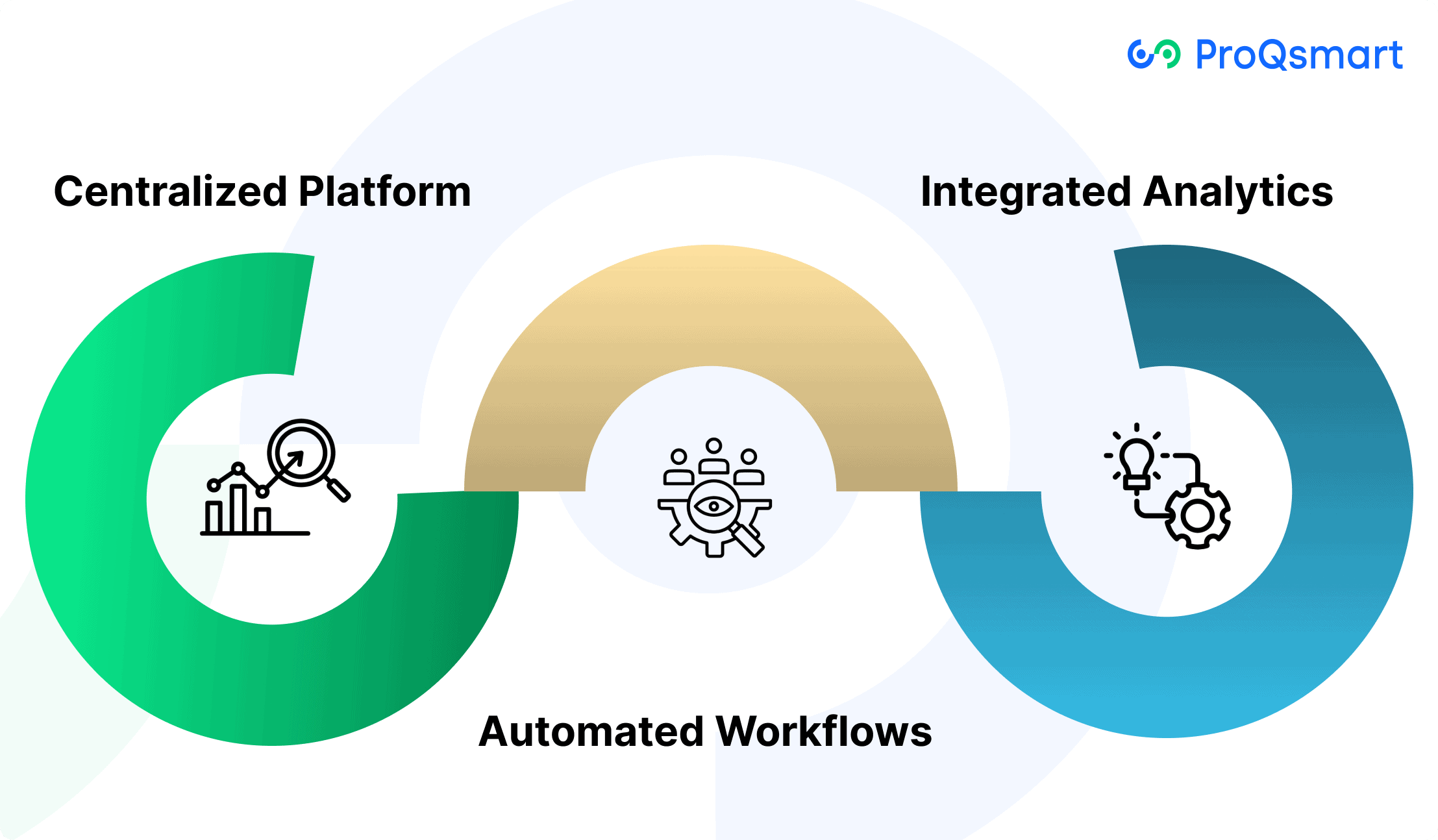

E-Sourcing Tools for Standardization

Centralized Platform

A centralized platform unites procurement teams in a single space, ensuring everyone accesses identical data and documentation. This is crucial for global companies or those that have different teams scattered everywhere. With tools such as ProQsmart, real-time collaboration is easier, enabling you to manage e-tenders, import bills of quantities and manage your subcontractors from a single dashboard. This transparency allows teams to monitor supplier performance without delay or ambiguity.

With all supplier information in one place, groups can easily view how vendors compare. The platform records all actions, providing a transparent, auditable trail for compliance and minimizing risk. With built-in chat and messaging, vendors and buyers can communicate instantly, resulting in better deals with less errors.

Automated Workflows

Automated workflows = less manual work and fewer errors. The tools help teams transition from sourcing to deal quicker, compressing what once took months to mere days—or hours with e-auctions. Companies can configure workflows to suit their processes, such as automatically triggering supplier audits or risk-flagging. Automation unburdens staff to spend time on supplier relationship building or spend planning, instead of paperwork chasing.

Integrated Analytics

Embedded analytics are essential for monitoring supplier performance and identifying where spend is directed. With dashboards and data visualization, teams can identify trends, benchmark vendors, and surface problems quickly. Ongoing analytics helps leaders guide strategy and adapt to market shifts, which counts as supplier risk and market swings can smack supply chains. By analyzing data frequently, businesses remain proactive and make wiser sourcing decisions.

Beyond Standardization: The Flexibility Balance

Although digital procurement tools might streamline and standardize RFx metrics, the requirement for flexible processes remains essential. Procurement units need to weigh the efficiency and cost savings against the risk of sacrificing agility in a shifting marketplace.

The Risk: When Standardization Goes Too Far

-

Boxed In by Rigid Rules: Hard-coded, one-size-fits-all metrics can leave teams unable to adapt when project needs shift or new supplier capabilities emerge.

-

Stifled Innovation: Overly strict standards discourage suppliers from proposing unique solutions, eroding engagement and limiting negotiation power.

-

Missed Opportunities: Without room to maneuver, organizations risk falling behind as market conditions and business priorities evolve

The Solution: Build Flexibility Into Your Process

-

Start with Strong Fundamentals: Set clear guidelines, but allow for project-specific adjustments when needed.

-

Pilot and Measure: Test flexible strategies on select projects, measure outcomes, and refine before scaling up.

-

Leverage Technology: Use e-sourcing platforms like ProQsmart for configurable workflows and dynamic scoring, enabling real-time tweaks to scoring parameters, vendor specs, or contract terms.

-

Continuous Feedback: Regularly gather input from stakeholders—team members, suppliers, and end users—to pinpoint where flexibility is most needed.

-

Ongoing Review: Keep processes fresh by routinely monitoring and updating metrics as business needs change

The Benefit: Agility, Innovation, and Stronger Supplier Partnerships

-

Flexible Frameworks Over Rigid Templates: Teams aren’t trapped by rigid templates or forced to reinvent the wheel for every project.

-

Boosted Supplier Confidence: Flexible processes encourage suppliers to bring their best ideas, fostering collaboration and more customized contracts.

-

Ready for Change: Agile procurement teams can respond quickly to disruptions, seize new opportunities, and drive sustainable innovation

Measuring The Standardization ROI

Measuring the return on investment (ROI) from standardizing RFx metrics with e-sourcing tools goes well beyond simple cost reduction. True ROI encompasses improvements in time savings, spend management, supplier performance, and risk mitigation. For procurement leaders, capturing and communicating these broader impacts is essential to demonstrating value and building the case for more efficient, resilient supply chains.

Key Performance Indicators (KPIs) for Standardization ROI

-

Time to complete sourcing events

-

Cost-per-sourcing event

-

Supplier defect rate

-

Cycle time reduction

-

Savings captured versus projected

-

Vendor management cost

-

Supplier on-time delivery rate

-

User adoption rate of new tools

Process Efficiency

Standardizing metrics streamlines workflows, enabling teams to move through sourcing tasks with greater speed and clarity. With digital tools and clear processes, RFx events are completed faster and with fewer obstacles. Automated reminders, digital document tracking, and standard templates reduce manual effort and minimize errors, allowing teams to focus on higher-value activities. Comparing sourcing cycle times before and after standardization provides clear evidence of these efficiency gains.

Cost Savings

Standardization empowers procurement professionals to negotiate better supplier terms by providing sharper comparisons and more data-driven insights. E-sourcing tools make it easier to identify and capture savings that might be missed in manual or ad hoc processes. Regular financial reviews, with targets set and tracked, ensure that cost reductions are not only achieved but also sustained over time.

Supplier Performance

With standardized metrics, procurement teams can consistently evaluate supplier quality, delivery reliability, and compliance. Clear KPIs—such as on-time delivery and defect rates—make it easier to identify high-performing suppliers and address areas for improvement. Reliable, transparent scoring builds trust with suppliers, fosters stronger relationships, and supports smarter, data-driven decisions for future contracts.

By focusing on these KPIs and leveraging digital sourcing platforms, procurement leaders can clearly demonstrate the full value of standardization—driving efficiency, cost savings, and improved supplier outcomes across the organization.

Future-Proofing Your Procurement Metrics: A Strategic Imperative

In a rapidly evolving business environment, static metrics quickly lose their relevance. Future-proofing your procurement metrics means continuously adapting them to align with shifting business goals and market dynamics—ensuring your sourcing strategy remains both effective and forward-looking.

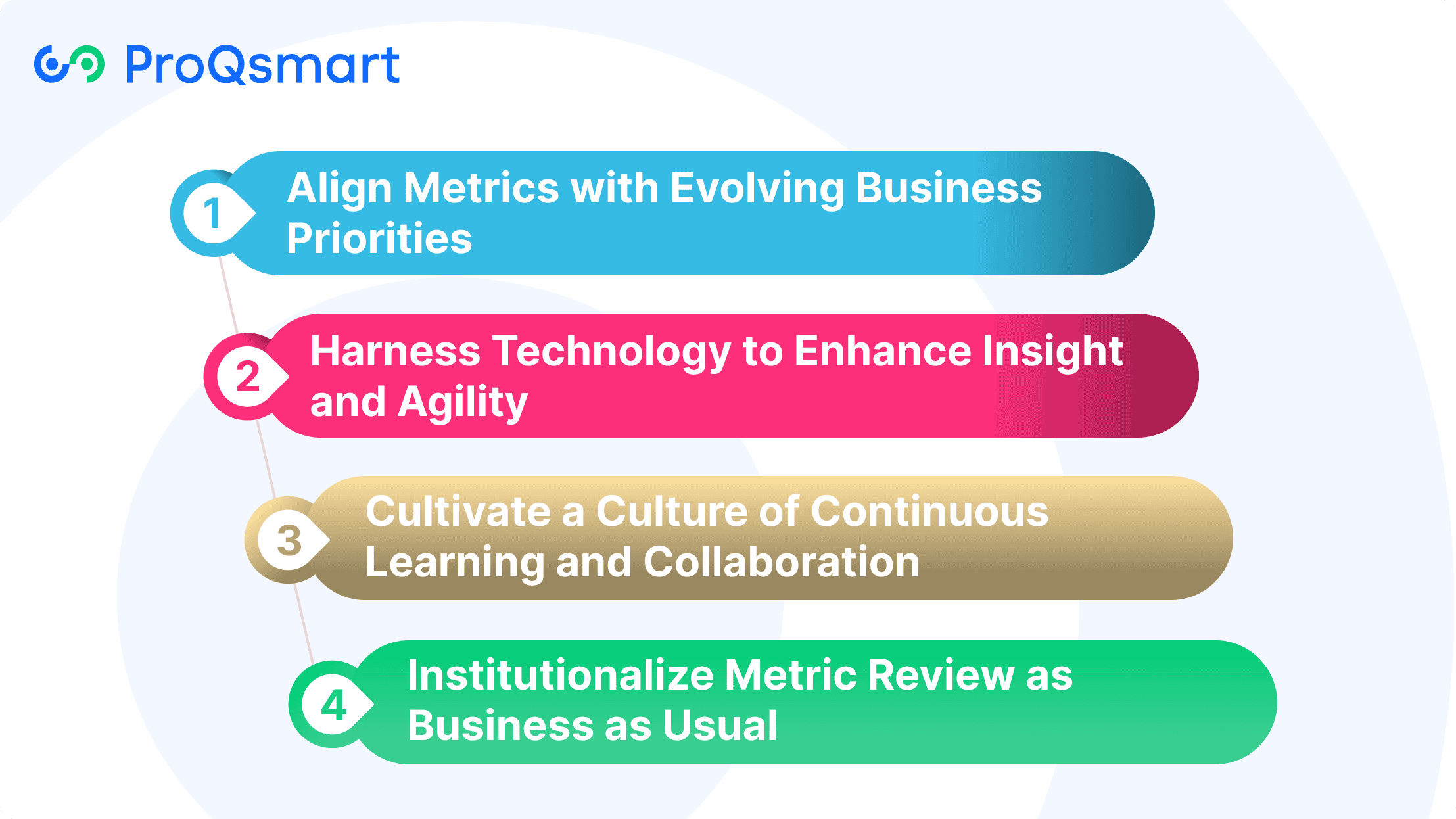

Align Metrics with Evolving Business Priorities

-

Regular, Scheduled Reviews: Establish a disciplined cadence for reviewing and updating metrics to reflect current and anticipated organizational objectives.

-

Balance Immediate and Strategic Goals: Design metrics that capture short-term performance while supporting long-term initiatives such as sustainability or supplier diversity.

-

Maintain Relevance: Ensure your KPIs evolve alongside changes in market conditions, regulatory landscapes, and corporate strategy.

Harness Technology to Enhance Insight and Agility

-

Integrated E-Sourcing Platforms: Utilize e-sourcing tools to standardize data collection, streamline performance tracking, and facilitate comprehensive trend analysis.

-

Automation and Predictive Analytics: Automate routine processes and leverage AI-driven insights to identify emerging risks and opportunities before they impact operations.

-

Data-Driven Strategy Adjustments: Employ advanced analytics to uncover subtle patterns, enabling proactive recalibration of procurement strategies.

Cultivate a Culture of Continuous Learning and Collaboration

-

Ongoing Training Programs: Invest in regular upskilling on emerging technologies, analytics, and procurement best practices to keep teams agile and informed.

-

Cross-Functional Alignment: Foster collaboration across departments to break down silos, ensuring all stakeholders operate from a unified set of metrics and objectives.

Institutionalize Metric Review as Business as Usual

-

Routine Metric Audits: Embed metric evaluation into standard operating procedures to maintain alignment with business needs and market realities.

-

Proactive Preparedness: Use consistent reviews to anticipate and respond swiftly to supply chain disruptions or market shifts.

Conclusion

Standardizing RFx metrics with e-sourcing tools empowers procurement teams with clear, reliable data, faster processes, and greater fairness in supplier evaluations. By eliminating guesswork and manual errors, teams can focus on making informed, strategic decisions that drive measurable business impact. These platforms are scalable for organizations of any size, support seamless vendor communication, and allow workflows to adapt as requirements change—without losing control or momentum. Risks are identified early, and performance gains are tracked with precision, ensuring procurement remains a value driver as business needs evolve. Book a demo with ProQsmart today and discover how your team can elevate procurement performance.