In manufacturing, strategic sourcing has emerged as a vital strategy for optimizing procurement processes. By aligning purchasing decisions with broader business objectives, organizations can unlock long-term value and enhance their competitive edge. Strategic sourcing involves a comprehensive analysis of total costs, a thorough evaluation of supplier capabilities, and the cultivation of strong, collaborative relationships with suppliers. This approach not only helps achieve cost savings and improve supplier performance but also mitigates risks and supports sustainability initiatives. By leveraging data-driven insights and market intelligence, businesses can streamline their procurement processes, ensuring operational efficiency and adaptability in dynamic markets.

In this guide, we’ll explore the proven strategies, tools, and best practices necessary for implementing an effective strategic sourcing framework tailored to your organization’s unique needs.

Strategic Sourcing Overview

A strategic approach to sourcing is much more than efficient buying. It’s a focused procurement strategy that helps you move toward your organization’s greater mission over time. This strategic approach marries data analytics, cost management and supplier relationship management.

Its aim is to identify value that is more than savings, while preserving or enhancing quality and service. This disciplined process concentrates on cost, quality and continuous improvement. It consists of eight iterative steps: review spending, conduct a market analysis, determine cost models, supplier selection, strategy development, negotiation, make the award, and manage the contract/measure results.

Strategic sourcing creates an environment of trust and collaboration, helping to build strong, strategic, long-term supplier relationships. Tools like ProQsmart proactively improve relationships by automating workflows and tracking performance. They help them align procurement with both budgets and with greater transparency, equity, and compliance.

Manufacturing Sourcing: Unique Challenges

Sourcing in the manufacturing sector is an even more elaborate process influenced by international supply chain corridors, cost and quality pressures, and market shifts. This complexity necessitates a robust strategic sourcing process that optimizes efficiency while ensuring resilience and adaptability in procurement activities.

Complex Global Supply Chains

Controlling global supply chains means dealing with these suppliers in various countries and continents, with each of those coming with different sets of challenges. Geopolitical tensions, economic instability, and cultural nuances sometimes play an outsized role in making procurements political, rather than straightforward business transactions.

For instance, sourcing from suppliers in various time zones and countries can result in longer lead times and increased communication challenges. In addition, regulations such as import/export restrictions and compliance requirements are all over the map, making things even more complicated.

In fact, as many as 35% of companies lack adequate supplier visibility, making it nearly impossible to drive sustainability initiatives. To enhance control, integrating tools like ProQsmart’s AI-driven platform can provide unmatched transparency, automate workflows, and monitor supplier performance, enabling manufacturers to maintain operational visibility and efficiency.

Intense Cost Reduction Pressures

Manufacturers continue to meet pressure on costs from every corner, even as they do their best to maintain supplier commitment and protect product integrity. While a focus on cost-cutting is often welcome, it can lead to a further erosion of supplier relationships and standards.

To reconcile these competing priorities, do the following focused strategies. Leverage ProQsmart’s budget driven procurement and real-time tracking to advance your sourcing decisions in line with fiscal objectives.

Aside from making subcontractor management more efficient, these tools improve quality by building trust and collaboration.

Maintaining Quality Standards

Ensuring consistent quality in sourcing is non-negotiable. Supplier evaluations and performance monitoring are crucial for maintaining high standards. ProQsmart’s features simplify these processes, offering tools like regular assessments and transparent reporting.

By embedding quality assurance into sourcing workflows, manufacturers can safeguard product integrity and reduce risks.

Adapting to Market Volatility

Today, market volatility means sourcing strategies must be nimble, and they should be guided by data — ideally, often real-time data. Scenario planning and maintaining a healthy, diverse supplier base help mitigate risks related to sudden disruptions.

Tools such as ProQsmart’s capital expenditure sourcing give manufacturers the ability to pivot quickly, making them long-term resilient.

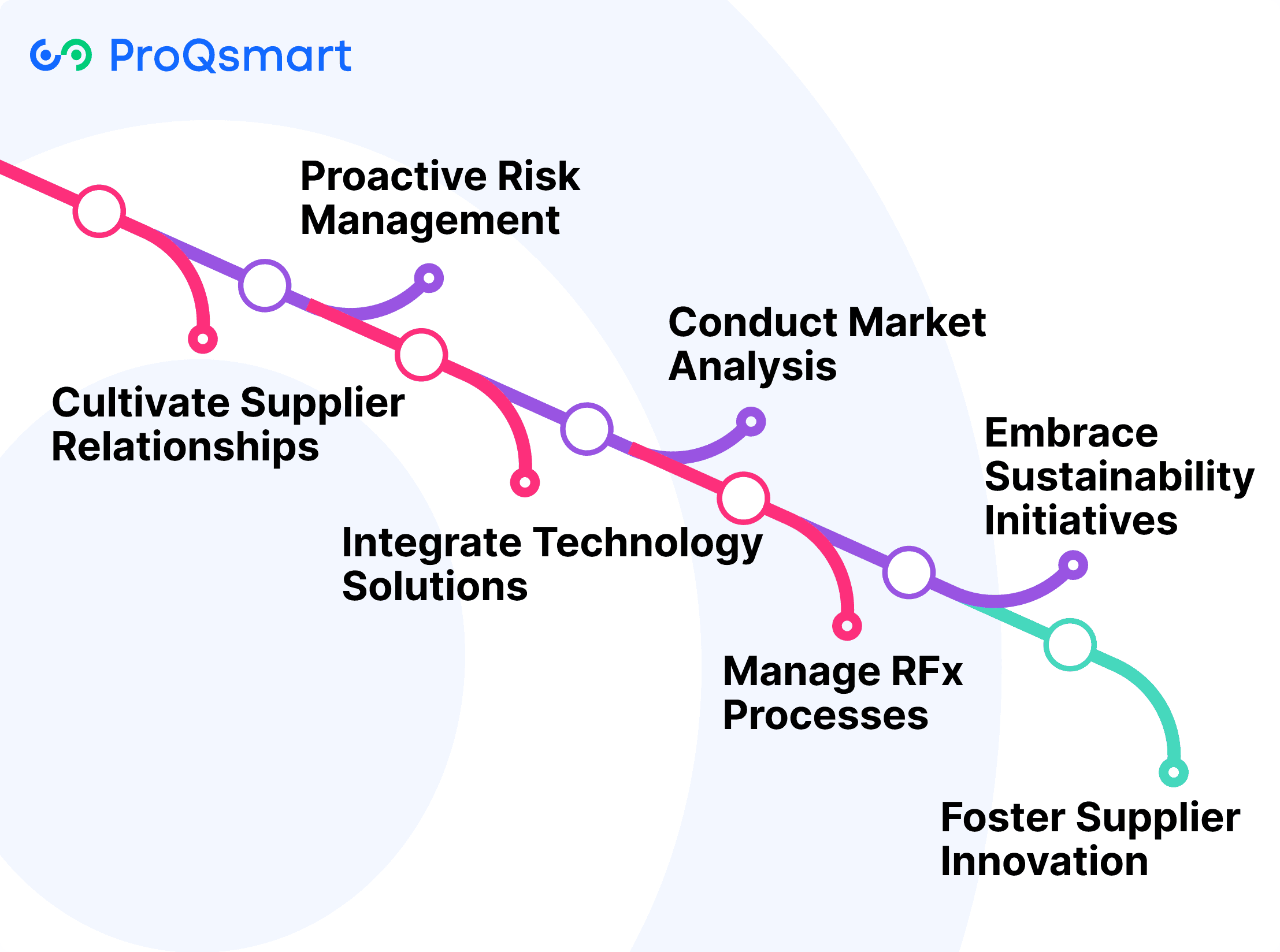

Strategic Sourcing: Key Strategies

Strategic sourcing is half data science, half ingenuity. This approach increases cost-effectiveness and improves quality. By placing an emphasis on collaboration, technology, sustainability, and innovation, procurement teams can realize tremendous value.

There are key strategies that support effective sourcing practices. Business Intelligence Below, I will explain each of these in detail.

1. Cultivate Supplier Relationships

Building a strong relationship with your suppliers is key. Building the relationship on foundations of trust and mutual benefit ultimately serves both sides with long-term reliability and performance.

Establishing open communication channels, promoting regular engagement opportunities, and creating transparent feedback loops allows for a culture of collaboration to thrive.

For example, frequent key performance indicator reviews with suppliers can remove roadblocks before they become problematic, while encouraging a culture of continuous improvement.

Mutually beneficial relationships build greater agility, as all 95% of companies that pivoted in the disruption of the pandemic found.

2. Proactive Risk Management

Identifying potential risks and preparing contingency plans are vital. Risk assessments help address vulnerabilities in supply chains, from material shortages to regulatory changes.

For example, segmenting suppliers into tiers, tier one and beyond, offers insights into compliance and resource allocation.

3. Integrate Technology Solutions

Using AI-powered platforms such as ProQsmart takes procurement to a whole new level. Its online e-tendering makes bids easy to compare, and robust decision analytics accelerate the decision-making process.

Automating supplier workflows and supplier performance monitoring keeps you ahead of any compliance issues and produces significant cost savings.

4. Conduct Market Analysis

Effective market research aids procurement professionals in identifying potential suppliers that meet or exceed our quality, pricing, and ethical expectations. Analyses like supply market analysis and competitive benchmarking help reveal strategic sourcing advantages worth pursuing.

5. Manage RFx Processes

A well-defined RFx criteria and a clearly structured strategic sourcing process will enable you to receive the most competitive bids. Well-defined timelines and clearly communicated expectations make it easy to measure supplier performance against procurement activities.

6. Embrace Sustainability Initiatives

Specifically, sustainability drives long-term value in the strategic sourcing process. Implementing ethical sourcing standards along with robust supplier engagement helps mitigate environmental impact.

7. Foster Supplier Innovation

Engaging suppliers in product design and development drives innovation within the strategic sourcing process. Rewarding their contributions supports an environment of creative risk-taking in supplier partnerships.

Strategic Sourcing Benefits in Manufacturing

Strategic sourcing in manufacturing is a dynamic, holistic approach that radically streamlines procurement processes and transforms the supply chain. By applying intelligent sourcing strategies, manufacturers can realize greater resilience, cost-effectiveness, and quality control, all while gaining a competitive edge.

Read on as we dive into these benefits and how strategic sourcing enables you to achieve these benefits – often in ways that are quantifiable.

Enhance Supply Chain Resilience

Strategic sourcing builds supply chain resilience by ensuring potential risks are identified and addressed from the outset. This includes making sure companies don’t rely too heavily on one supplier so that production can continue in the face of emergencies and other upheaval.

Continual tracking of supplier performance keeps delivery schedules and product quality on track. For instance, establishing duplicate suppliers creates additional protection against supply disruptions, allowing manufacturers to pivot quickly when unexpected situations arise.

Achieve Significant Cost Savings

By leveraging strategic sourcing, manufacturers can ensure the best competitive pricing, cutting procurement costs by up to 15% according to research. This is where effective negotiation strategies come into play, enabling businesses to secure advantageous terms and arrangements with suppliers.

Factoring in total cost of ownership helps to minimize costs over time, and buying in bulk or establishing multi-year contracts can further increase savings. ProQsmart’s AI-driven platform is proactive, not reactive, and actively automates workflows.

Most notably, it connects procurement processes to budgeting, which allows governments to leverage procurement to achieve more cost savings.

Ensure Consistent Quality

From a market perspective, consistent quality is important to customer perception as well. Intuitive quality control strategic sourcing establishes quality benchmarks and performance metrics upfront, so suppliers are responsible for delegating quality control within defined parameters.

Comprehensive, consistent reviews and strong quality assurance practices uphold these high standards at every step of the procurement process. Tightening relationships with capable suppliers, made easier through avenues like ProQsmart, consistently enhances material quality and ensures on-time, dependable deliveries.

Improve Project Profitability

Strategic sourcing helps to connect procurement with the needs of the project, ultimately powering profitability. Setting cost-effective terms with suppliers through effective negotiation and ongoing monitoring of project impacts helps to ensure sourcing decisions are contributing to project success.

Tools including transparent platforms such as ProQsmart further streamline this alignment, enabling effective go-to-market execution.

Drive Competitive Advantage

By encouraging innovation, sustainability, responsiveness to the market and priorities, strategic sourcing provides manufacturers a competitive advantage.

On-going evaluation of sourcing strategies is crucial to ensure they adapt to ever-changing industry trends and requirements. This method promotes operational efficiency, lowers environmental impact, and enhances social responsibility, ensuring companies remain competitive.

Measuring Strategic Sourcing Success

Strategic sourcing is an ongoing discipline focused on improving the effectiveness of procurement and providing long-term commercial value. Measuring its success takes a disciplined approach – one with clearly defined metrics, a thorough financial analysis, and regular review every step of the way.

Learn realistic approaches to better connect your sourcing strategies with your organization’s objectives. Being data driven is going to be the key to unlocking growth in the long term.

Key Performance Indicators (KPIs)

Setting KPIs is basic for measuring strategic sourcing success. Real-world metrics like cost savings, supplier performance, and quality assurance speak volumes to the success of your strategic sourcing strategy.

Measuring cost savings allows for a transparent understanding of what’s happening financially. Through better supplier negotiations, companies have been able to save an average of 15% on procurement costs.

Supplier performance metrics, such as on-time delivery rates and defect rates, help maintain quality commitments in the supply chain. Quality assurance, evaluated by inspection outcomes of products commodities, enhances adherence to specifications.

Dashboards take these KPIs and make them visual representations. Most importantly, they empower stakeholders to easily monitor progress over time, contextually, and make smart, data-informed decisions.

ROI Calculation Methods

Measuring ROI in strategic sourcing is a delicate balance between calculating both the tangible and intangible savings. Direct savings may be through lower material expenses, and indirect through increased operational efficiencies or risk avoidance.

Benchmarking against industry standards aids in understanding competitive positioning, ensuring strategies remain robust. Regularly reviewing ROI calculations allows for adjustments and helps leverage tools like ProQsmart’s AI-driven platform, which streamlines processes and aligns procurement with budgets through real-time tracking and supplier performance monitoring.

Long-Term Value Assessment

Strategic sourcing focuses on delivering long-term value, not just short-term savings. Supplier relationship health, innovation contributions, and market positioning—all more difficult to measure than spend—are leading indicators that can be critical to strategic success.

Proactively evaluating relationships through an equity lens can identify collaborative opportunities for innovation. Stakeholder feedback can help your strategies stay strategic and comprehensive.

Sophisticated solutions, such as ProQsmart, bring much needed transparency and automation to the process, enabling organizations to achieve sustainable procurement excellence.

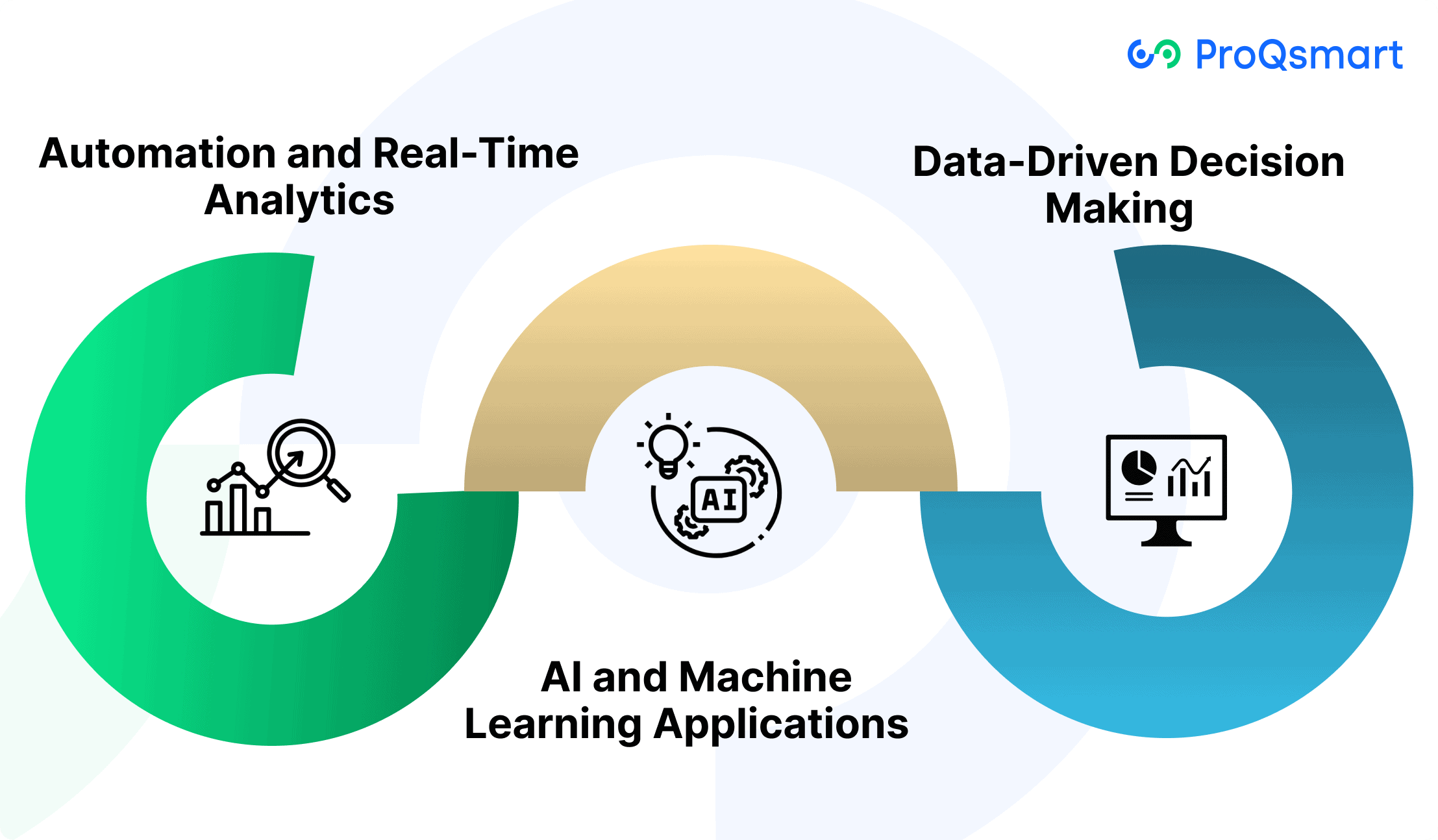

Technology’s Role in Strategic Sourcing

The evolution of technology has opened a whole new world to strategic sourcing. By automating repetitive tasks, providing real-time insights, and harnessing the power of data, technology enables sourcing teams to make informed decisions, improve efficiency, and drive long-term value.

In an era where businesses must adapt to dynamic supply chain challenges, leveraging advanced tools is no longer optional but essential.

Automation and Real-Time Analytics

Automation removes the burden of labor-intensive, manual tasks which improves accuracy and promotes best practices by creating repeatable, standardized sourcing processes. Day-to-day tasks like vendor selection, contract management, and invoice processing are automated, liberating teams to spend more time on strategic initiatives.

Real-time analytics further enhance this by enabling continuous monitoring of supplier performance, identifying inefficiencies, and ensuring alignment with procurement goals.

Collaborative technologies help enhance real-time communication and collaboration between various sourcing teams, suppliers, and other stakeholders to help make informed decisions faster.

AI and Machine Learning Applications

AI and machine learning have transformed the world of sourcing by providing predictive analytics and actionable insights. These technologies leverage artificial intelligence and machine learning to scour billions of datasets to predict market fluctuations, evaluate supplier risks, and suggest optimal procurement strategies.

AI-fueled proctoring tools like ProQsmart make arduous tasks like e-tendering, supplier performance oversight, and subcontractor tracking far easier. When AI is embedded deep within sourcing workflows, organizations start to realize a huge competitive advantage through better cost savings, transparency, and compliance.

Data-Driven Decision Making

Data provides the basis for all strategic sourcing activities. Analytics tools provide critical insight into supplier performance, spending patterns and market dynamics, which continuously improve processes.

Fostering strong data governance procedures helps to assure the quality of insights, providing the confidence needed to make smarter decisions. ProQsmart’s budget-driven procurement feature is a great example, connecting all sourcing activities with real-time financial tracking.

Aligning Sourcing with Sustainability

Aligning sourcing strategies with sustainability goals has become essential for businesses striving to meet modern consumer expectations and regulatory demands. By integrating a strategic sourcing process with sustainability objectives, organizations enhance their operational effectiveness. This approach not only benefits the planet but also delivers real environmental, social, and economic advantages.

Environmental Impact Reduction

To reduce the environmental impact of sourcing activities, companies should implement a strategic sourcing plan that incorporates low emissions sourcing strategies. Engaging your supply chain partners to adopt eco-friendly materials and innovative manufacturing practices is essential for maximizing sustainability impact. Providing requirements to support a green supply chain is crucial in this procurement process.

Evaluating suppliers through a robust supplier evaluation process that considers sustainability standards, such as ISO certifications, ensures compliance with sustainability goals and policies. For example, businesses can significantly reduce Scope 3 emissions by collaborating with potential suppliers on carbon footprint reduction initiatives throughout the supply chain.

Setting measurable sustainability goals, such as reducing waste or increasing recyclable packaging use, guarantees that efforts remain transparent and results-oriented. With 57% of consumers preferring products with sustainable packaging, these strategic sourcing solutions directly influence consumer choices and enhance brand loyalty.

Ethical Sourcing Practices

Incorporating ethical values into sourcing not only bolsters public and employee confidence, but helps avoid ethical faux pas. Implementing regular, independent supplier audits is an essential step to ensure suppliers are upholding fair labor practices and ethical sourcing standards.

Clear and documented supplier expectations, underlined by a comprehensive supplier code of conduct, create further accountability with the supplier. ProQsmart simplifies these processes by automating workflows, managing compliance data, and offering real-time collaboration tools that enhance supplier performance monitoring.

Promoting Social Responsibility

Ensuring social responsibility in sourcing improves community development efforts and labor conditions. Organizing suppliers around any effort, whether it’s building education and training programs or establishing equitable pay practices, generates that shared value.

Aligning with sourcing strategy partnerships that place a strong social focus goes beyond consumer demands, building longer-lasting supplier loyalty.

Conclusion

Strategic sourcing strengthens U.S. Manufacturing supply chains. It reduces costs, increases supplier performance, and fuels long-term economic development. When these sourcing strategies are guided by clear goals, rigorous relationships, and prudent technology, they lead to concrete outcomes. Risks remain lower, workflows remain more efficient, and sustainability becomes an achievable everyday goal.

Measuring success helps identify what’s really working and what just needs a little adjustment. Beyond accountability though, it provides teams with the tools to continue improving. When strategic sourcing practices lead to more sustainable sourcing, it’s a win-win for the business and the planet. Each decision matters, from deciding which suppliers to use, to prioritizing supplier sustainability audits.

To take your sourcing strategy to the next level and prioritize initiatives that produce the greatest value, consider leveraging cutting-edge tools. Book a demo with ProQsmart today to discover how ProQsmat’s advanced sourcing solutions can help you enhance your procurement processes, strengthen supplier relationships, and drive business growth.