Good supplier agreement management process is essential for maintaining the efficiency of your organization’s procurement processes and therefore, operational business success. When companies prioritize cultivating collaborative supplier relationships, they can obtain more consistent quality, improved pricing, and reliable deliveries.

Good management means regular communication and performance tracking to ensure suppliers’ goals are in alignment with the organization’s needs. It further aids in tackling barriers such as risk mitigation, compliance assurance, and market demand adaptability.

By establishing a comprehensive supplier management strategy, organizations can improve their supply chain resilience while positioning themselves for long-term growth. Leveraging tools and data-driven insights can take efficiency even further and help you better align and collaborate with your suppliers.

This strategy doesn’t just cut costs, it helps foster sustainability practices, creating more value for companies and their suppliers.

What Is Supplier Agreement Management?

Supplier Agreement Management (SAM) focuses on the long-term and short-term strategy of managing agreement with suppliers. This helps make sure that their roles are focused on achieving the organization’s goals. At its core, SAM exists to control the supplier relationship by dictating how terms are established, tracked and delivered.

It isn’t simply enough to enforce contracts—it’s building collaborative relationships that lead to innovation, efficiency, and ultimately stronger projects that benefit everyone. Clearly define terms and conditions for the project. Provide a clear outline of deliverables, timelines, budgets, and acceptance criteria so all parties are aware of their obligations from the outset.

Importance of Supplier Agreement Management

Supplier agreement management is crucial for a reliable supply chain, particularly when considering supplier relationship management. Well-structured agreements clarify expectations and responsibilities, enabling swift responses to disruptions like supplier loss or market changes. Efficient agreements help identify top-performing suppliers, enhancing operational continuity and resilience. Strong supplier partnerships foster collaboration, improving forecasting, lead times, and reducing waste, which leads to cost savings and smoother workflows. Effective management also ensures regulatory compliance by keeping contracts organized. Tools like ProQsmart can track agreement terms and automate compliance management, minimizing risks. Collaboration with suppliers drives innovation through open communication, ultimately enhancing customer satisfaction.

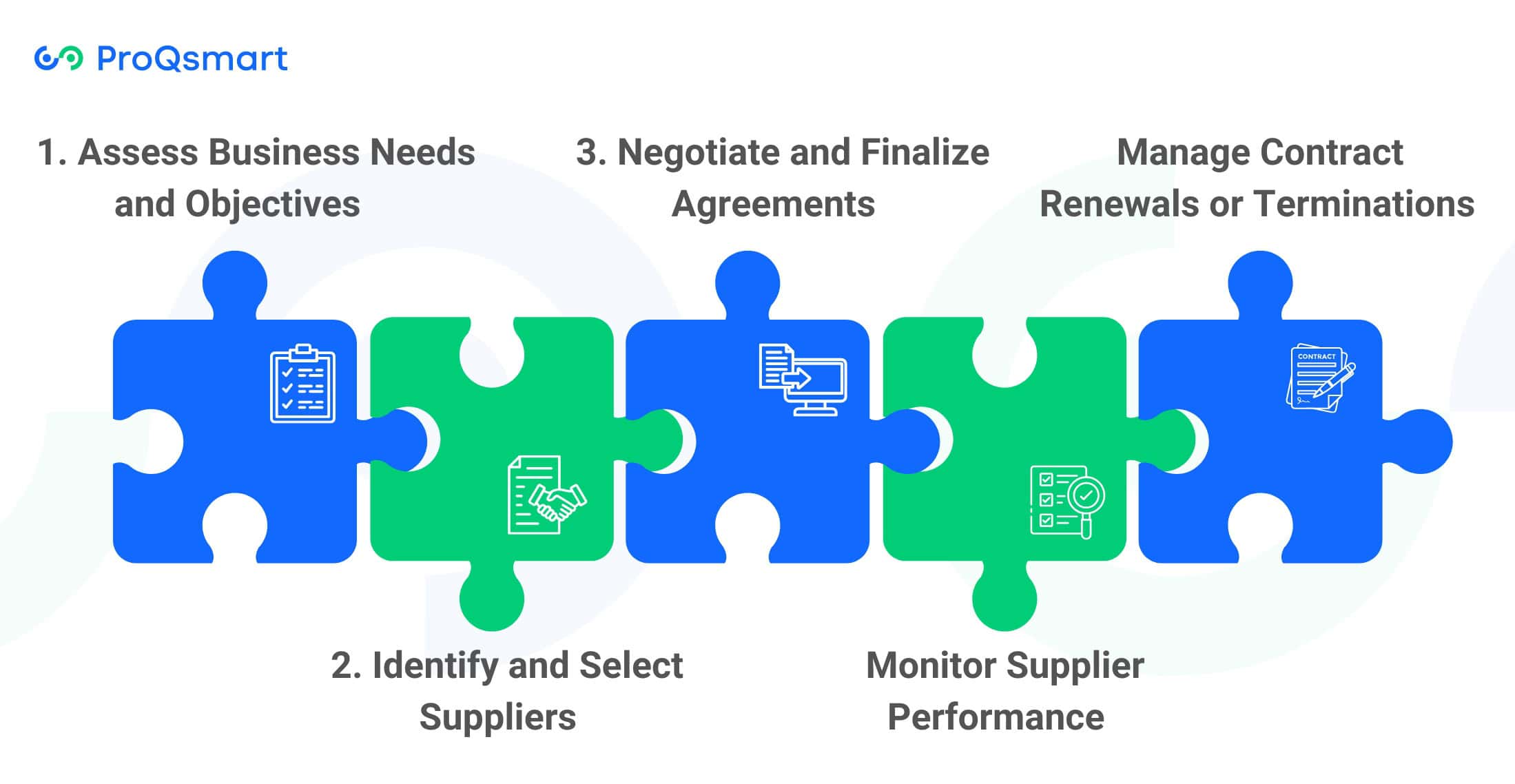

Supplier Agreement Management Process

Supplier agreement management has become a critical, foundational process in procurement. It includes all the details of vendor relationships, including terms, warranties, ongoing support, etc. This highly structured process helps to clarify roles and responsibilities and manage changes efficiently.

Below, we take a deep dive into the crucial steps for effectively managing supplier agreements, supplemented with practical tips and illustrative examples.

1. Assess Business Needs and Objectives

The first step is understanding your organization’s goals. For example, if minimizing production disruptions is a goal, then supplier on-time delivery is an important KPI. Establish KPIs that reflect these objectives, whether it be in the form of cost savings, quality metrics, or other relevant targets.

For example, a construction firm focused on sustainability might choose suppliers with experience in providing eco-friendly materials and practices. Clearly communicating these requirements to potential suppliers helps ensure alignment from the outset, fostering a collaborative approach to green building initiatives.

2. Identify and Select Suppliers

A more systematic approach makes it easier to identify quality suppliers. Consider qualification criteria such as financial stability and compliance history. Additionally, supplier questionnaires can be used to evaluate a prospective vendor’s ability to quickly fulfill bulk orders.

Ranking your suppliers helps you choose the ones that are most appropriate for your current needs, for example prioritizing local vendors who can deliver faster.

3. Negotiate and Finalize Agreements

Preparation is everything when it comes to successful negotiations. Keep an eye on market trends and research suppliers industry to get a sense of pricing benchmarks. Do avoid vague language and clarify terms such as payment schedules and warranties.

An all-sides-winner agreement could involve some mix of volume discounts and measures to protect supplier margins. Taking risks, like allowing for delays, reduces the likelihood of future conflicts.

4. Monitor Supplier Performance

Regular reviews against established KPIs ensure that the supplier management processes are effective. Performance data helps you track a supplier’s delivery timelines and product quality, for instance. Open lines of communication facilitate successful supplier relationships, allowing both sides to continue improving.

5. Manage Contract Renewals or Terminations

Don’t wait until a renewal decision to start discussions—not even close to it. By taking the time to review historical performance and exploring alternatives, you can ensure you’re making an informed decision.

When termination becomes unavoidable, exit strategies, such as a move to a secondary supplier, reduce the impact.

Supplier Management in Procurement

- Supplier management processes are vital for the long-term success of procurement strategies. By integrating supplier relationship management into procurement, organizations can align supplier capabilities with their goals. For example, if cost reduction is a priority, partnering with suitable suppliers that offer discounted rates or establishing long-term contracts can help mitigate price volatility.

- Effective supplier management enhances procurement efficiency through systematic supplier management. Utilizing supplier management software automates workflows, reduces manual errors, and aids in decision-making. Centralized tools are especially beneficial for large enterprises managing numerous suppliers, as they provide a comprehensive view of performance and compliance.

- Strong supplier relationships are equally important for successful supplier partnerships. Regular communication and collaboration foster innovation and mutual growth. Conducting quarterly reviews with key suppliers to assess performance and set goals can strengthen these relationships. Recognizing exemplary service boosts morale and encourages high standards across the board.

- Risk mitigation is essential in the supplier onboarding process. Establishing compliance frameworks and conducting regular audits can identify potential risks early on. Proactive measures like contingency planning help minimize disruptions. Ultimately, procurement teams must lead cross-functional collaboration to ensure resilience and adaptability in the supply chain.

Best Practices for Supplier Management

In an increasingly competitive climate, effective supplier relationship management is more important than ever to realize operational efficiencies and cultivate long-term business success. Below are some best practices to help you navigate supplier management processes with confidence and precision.

Establish clear communication channels with suppliers.

Develop strong evaluation criteria for supplier selection.

Foster long-term partnerships through collaboration.

Leverage data analytics for insights into supplier performance.

Establish Clear Communication Channels

Establishing clear communication protocols is a crucial step in effective supplier relationship management to ensure that suppliers are engaged regularly. By documenting expectations for response times, reporting formats, and the escalation process, you can keep everyone aligned and avoid costly delays in the supplier management process.

Adopting a multi-channel approach that includes email, video conferencing, and supplier portals meets suppliers where they prefer to communicate, enhancing the overall supplier onboarding experience. Regular quarterly updates with key suppliers provide the ideal balance of communication frequency, ensuring that you maintain strong relationships without overwhelming them.

These one-on-one meetings foster accountability and transparency, serving as a forum for problem-solving when necessary. By documenting conversations and feedback, you not only create accountability but also uncover new opportunities for improvement in your supplier management strategies.

Develop Strong Evaluation Criteria

Effective supplier evaluation begins by determining what metrics are most important, such as quality, lead time, pricing, and ability to innovate. A scoring system helps rank suppliers, making it easier to prioritize relationships. Engaging with cross-functional teams provides a holistic view to the evaluation process.

Because business needs change, criteria should be repeatedly updated to ensure they accurately reflect the priorities of the present day. For example, making sure you’re harmonizing supplier evaluations with sustainability objectives can help build win-win collaborations.

Accurate, centralized supplier data is the backbone of an effective evaluation process.

Foster Long-Term Partnerships

Joint planning sessions can help ensure that larger supplier goals align with your organizational objectives, a true win-win situation. Even minor efforts, such as acknowledging supplier accomplishments in company-wide meetings, help to establish them as key strategic partners.

Offering resources, like training programs or market insights, demonstrates a commitment to the supplier’s growth and success. Encouraging collaboration on new initiatives or process improvements can unlock innovative solutions and strengthen business resilience in a volatile market.

Leverage Data Analytics for Insights

What’s clear is that data analytics has become indispensable for supplier management. Procurement tools such a ProQsmart can analyze procurement data easily and quickly find trends in performance and opportunities for cost savings.

Predictive analytics, for instance, can help you predict what your future needs will be so your suppliers can plan ahead. This data further assists in monitoring compliance, as well as risks.

By sharing these insights with suppliers, you’re able to collaboratively problem-solve and build a culture of continuous improvement.

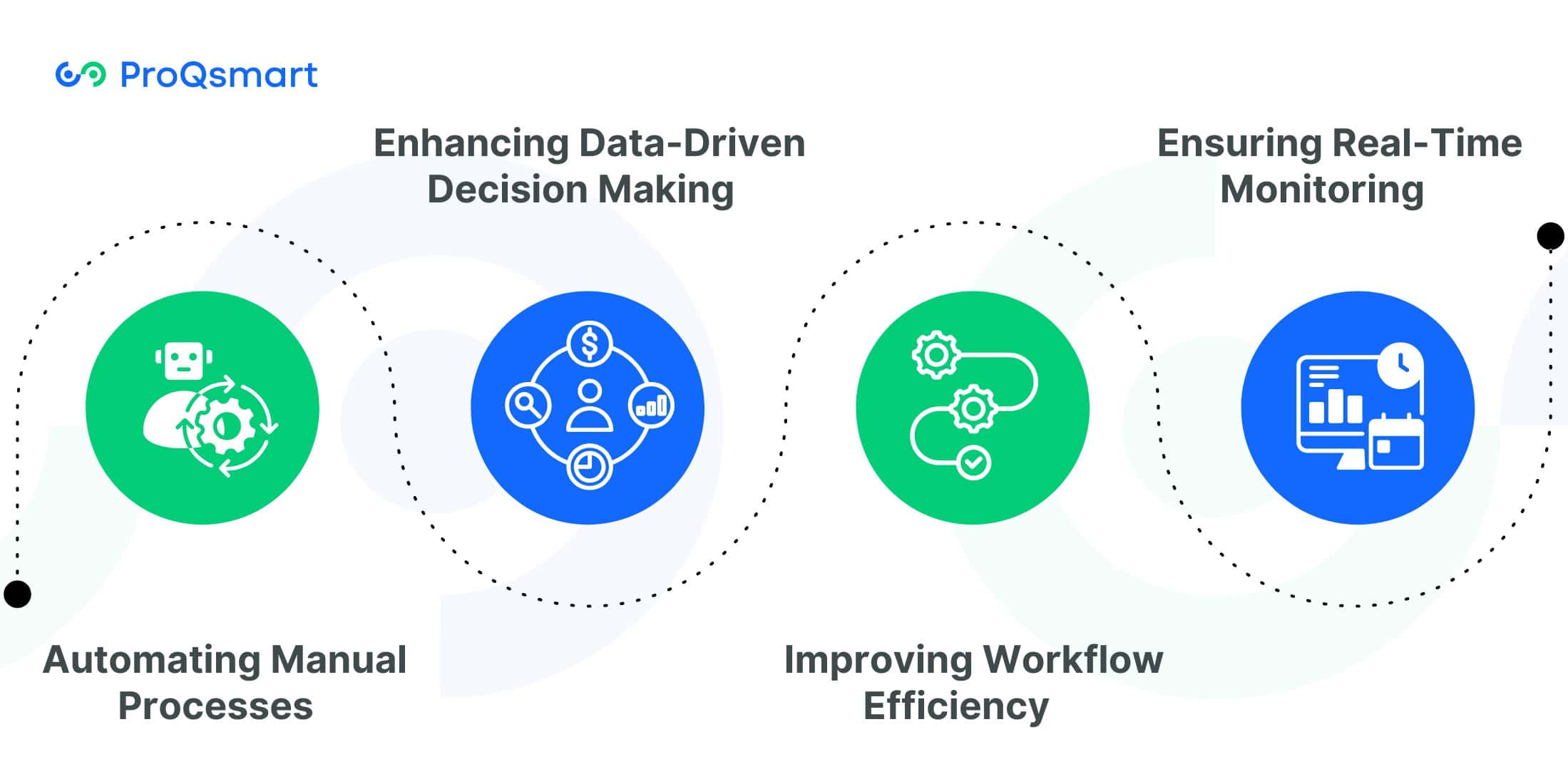

Role of Technology in Supplier Agreement Management

Automating Manual Processes

Technology has played a huge role in revolutionizing supplier agreement management, particularly through automation. It helps procurement teams break away from time-intensive data entry, allowing them to spend more time on strategic initiatives through supplier management software.

Digital solutions simplify reporting requirements while eliminating thousands of pages of paperwork, slashing administrative overhead and project cycle times. Take ProQsmart, which provides automated workflows, leading to improved compliance and better organization of documents with features such as e-tenders.

These systems dramatically increase efficiency. They help to centralize supplier information, a top priority for 58% of organizations surveyed.

Enhancing Data-Driven Decision Making

Data analytics is key to effective supplier management. With the power of analytics, procurement teams can more easily decide which suppliers to engage with and how to evaluate their performance.

Specific metrics such as delivery timelines or quality standards offer measurable expectations that create more on the ground accountability, creating more alignment with larger organizational priorities. For example, ProQsmart connects supplier performance monitoring and evaluation to real-time tracking, which allows companies to quickly identify trends and risks.

Sharing these insights with relevant stakeholders only serves to better align procurement strategies across teams. Building a culture of data-driven decision-making helps keep procurement teams one step ahead.

Consistently checking your data feeds for accuracy is key. Connecting analytics with current workflows addresses one of the key obstacles to effective programs.

Improving Workflow Efficiency

Mapping out supplier management workflows can help you identify areas to improve and streamline processes, cutting out bottlenecks that drag your operations to a crawl. Collaboration features, such as those found in ProQsmart’s tools, encourage collaboration, reducing time and effort needed to complete tasks.

Project management tools take this tracking a step further, making it easy to track progress on supplier-related tasks and maintain transparency and accountability throughout the process. By regularly evaluating their efficiency, teams can continuously adjust their workflows to meet changing demands and maintain peak productivity.

Ensuring Real-Time Monitoring

Real-time monitoring systems are essential for ensuring ongoing supplier performance. Dashboards with Key Performance Indicators (KPIs) give you instant insight into areas of contract compliance or risk.

ProQsmart’s supplier performance monitoring system automatically sets alerts for deviations, enabling teams to take action before something goes wrong. Sharing results with suppliers creates accountability and builds relationships that improve performance even more.

Benefits of Optimized Supplier Agreement Management

Optimized supplier relationship management offers numerous advantages that empower businesses to thrive in a competitive market.

Achieve cost savings and efficiency gains.

Strengthen supplier collaboration for better outcomes.

Improve the quality of deliverables from suppliers.

Reduce operational risks through effective management.

Cost Savings and Efficiency Gains

An optimized approach to supplier agreement management enables procurement teams to explore their processes like never before. They can help you find places to save on dollars without sacrificing quality. For instance, securing better terms with suppliers, such as discounts for bulk purchases or longer payment deadlines, can have an immediate positive impact on profits.

With the right tools to automate processes, companies can cut out unnecessary steps, slashing costs and time lost to inefficiency. Frequent analysis of spending patterns can reveal trends that lead to more informed supplier selection, guaranteeing the most value for each dollar spent.

Adopting best practices, such as automating contract management, eliminates manual errors, speeds up approvals, and ensures policy compliance, leading to significant efficiency gains.

Strengthened Supplier Collaboration

Building strong relationships with suppliers begins with transparent communication. Providing transparency around agreed-upon expectations and collaborating to overcome obstacles strengthens trust and lays the foundation for innovation.

For example, suppliers can participate in collaborative sessions to generate ideas for product innovations or process efficiencies. When successful collaborations are acknowledged, it increases the morale of all involved and strengthens these crucial partnerships.

Aligning internal and external efforts through agreed-upon shared goals helps make sure both parties are focused on driving mutual success. Iterative feedback loops allow teams to continually refine strategies for collaboration, resulting in a more collaborative environment that fosters improved outcomes.

Improved Quality of Deliverables

Quality deliverables start with setting clear expectations for suppliers. Monitoring performance against metrics ensures accountability and consistency. Providing effective feedback helps suppliers improve their work and gives them the opportunity and motivation to exceed requirements.

Cross-organizational quality improvement efforts, like joint training events or process audits, reinforce the entire supply chain. Celebrating high-performing suppliers encourages others to strive for excellence, ensuring a steady flow of superior outcomes that support all stakeholders.

Reduced Operational Risks

Spotting risks sooner, like supply chain disruptions or compliance deficiencies, can be key. Strategies such as centralizing all vendor data help minimize risks of fraud and errors and improve timely payments.

For instance, a centralized contract management system allows for easier and faster retrieval of contracts, preventing a loss or delay from occurring. Keeping an eye on external factors, like market trends, helps ensure that businesses are ready to face supplier challenges.

Encouraging proactive risk management within teams ensures preparedness, while regularly updating risk plans adapts to changing conditions, ensuring stability in an unstable economy.

Continuous Improvement in Supplier Management

As more organizations are realizing, continuous improvement in supplier management processes is vital for organizations that want to succeed in today’s competitive markets. Rooted in the Kaizen philosophy, it’s all about the small, daily, continuous changes—not the dramatic, once-in-a-blue-moon revolution. Such an approach sets an organization up for long-term success by keeping supplier performance aligned with rapidly changing business goals.

Regularly Evaluate Supplier Performance

Continuously evaluating suppliers is crucial for aligning them with your organization’s goals and objectives. Implementing consistent supplier management processes, such as regular performance reviews at least once a month or quarterly, helps track results effectively. Establish key performance indicators (KPIs) like on-time delivery rates and defect rates to create measurable goals that enhance supplier performance.

As an example, a simple monthly scorecard approach offers up immediate feedback, often resulting in 15% to 20% quality improvements among suppliers. Solicit feedback from internal stakeholders such as production or quality control to get a full picture. When business needs change, adjust business metrics to continue to make them relevant.

Transparency is key—publish evaluation results for all suppliers and collaborate on improvement plans as necessary. For underperforming suppliers, leveraging data-backed insights can inform targeted improvement strategies, ensuring successful supplier relationships.

Adapt to Market Dynamics

Supplier performance can be heavily affected by market conditions. In addition to following industry reports, you should keep an eye on your suppliers. For instance, contracts that provide for flexibility in the face of raw material shortages or price volatility are helpful.

Engage in open dialogue with suppliers on how to tackle mutual issues, setting the groundwork for a strong partnership. Keeping a pulse on the competition will help you identify profitable strategies, so your organization doesn’t fall behind the curve.

Using technology such as supplier management software makes it easy to keep track of these changing dynamics, giving you real-time insights.

Invest in Training and Development

Often overlooked, procurement teams are the unsung heroes of effective supplier relationship management. Providing educational opportunities, like workshops or webinars, tailored to best practices and emerging trends can greatly enhance supplier management processes. Additionally, fostering a culture of continuous improvement through regular peer-to-peer knowledge-sharing sessions can strengthen supplier partnerships.

For instance, building a culture of continuous learning not only re-engages teams but also hones long-term supplier management capabilities. Evaluating the success of training initiatives by measuring the impact on key metrics like defect rate reduction or faster deliveries is crucial for ongoing supplier relationship success.

Providing financial support for professional certifications deepens the expertise of your team, which ultimately pays dividends with strong supplier relationships and enhances the overall supplier management process flow.

Conclusion

Supplier agreement management is a critical pillar of best-in-class procurement systems, leading to clearer agreements, stronger relationships, and improved operations. A well-managed supplier network reduces risks, cuts costs, and enhances efficiency, ultimately driving organizational success. By leveraging tools like contract lifecycle management software and data analytics, procurement processes can become more targeted and time-efficient.

Effective supplier management requires ongoing evaluation and transparent communication to maintain mutually beneficial partnerships that meet evolving needs and objectives. It is not a one-time project but a continuous effort that demands focus, adaptability, and a commitment to learning from performance metrics. Companies that prioritize supplier management can achieve sustained value and maintain a competitive edge.

Ready to elevate your supplier management strategy? Book a demo with ProQsmart today to explore how our solutions can help you enhance your supplier relationships and drive procurement success!