Supplier management is an ongoing process of managing and developing supplier relationships to drive long-term quality, efficiency, and competitiveness. This ensures seamless operations, cost efficiency, and quality assurance in procurement.

It’s about managing supplier performance, driving contract negotiations, and creating collaborative partnerships to meet the goals of the organization. Strong supplier management practices can help businesses mitigate risk, streamline supply chains, and keep prices competitive.

You should have a good understanding of what’s involved with effective supplier management. From compliance and communication to performance tracking, regardless of if you’re managing one supplier or a whole network of them.

In this blog, we’ll dive into some of the most effective, actionable strategies procurement professionals can implement. Following these best practices will improve their supplier management processes and help fuel sustainable, profitable growth for their organizations.

Why Supplier Management Matters in Procurement

As the business landscape continues to evolve at an unprecedented pace, strong supplier relationships have become one of the key cornerstones of successful procurement. It’s not just about selecting the right vendors—effective supplier management actually drives the results of projects by holding them accountable for performance and managing risks.

Procurement accounts for over half of all business expenditures. To reduce costs without sacrificing quality or efficiency, a smart approach to the supplier management process is essential.

Perhaps the greatest effect of supplier management can be found in the ability to track key performance indicators (KPIs). Developing specific, measurable, attainable, relevant, and time-bound (SMART) goals for each supplier, based on overall business goals, provides clear metrics to gauge success.

By tracking on-time delivery rates and cost-saving contributions, procurement can put exemplary supplier performance on display. Beyond that, it pinpoints specific areas where they can do better.

Supplier management plays a critical role in minimizing risks, such as disruptions or compliance failures. By segmenting suppliers based on importance and risk, conducting thorough due diligence, and continuously evaluating third-party risks, businesses can build a more resilient supply chain.

Platforms such as ProQsmart make this easier by providing AI-driven tools that automate workflows, proactively monitor performance, and address compliance. These features not only help reinforce relationships between parties, they lead to greater efficiency and cost savings, fostering stability and growth in the long term.

Supplier Management Challenges in Construction

Supplier management in the construction industry comes with its own distinct challenges that require the utmost consideration and deliberate effort. Fragmentation within supply chains is still an ongoing challenge, as old communication practices hinder fast response times and overall productivity.

This reliance on outdated practices often results in communication gaps, complicating efforts to achieve seamless collaboration. From a quality control perspective, this can lead to major issues if priorities shift depending on the department or if a long nominating process slows down supplier sourcing. For example, procurement professionals often take months to qualify suppliers, which slows down project schedules.

Supply Chain Disruptions

Unexpected natural disasters like hurricanes or floods often force highly vulnerable construction supply chains, stopping essential deliveries of materials. Without these contingency plans in place, such disruptions can cascade down project schedules, exacerbating costs and causing further delays.

Modern technologies such as IoT devices and supplier management software improve overall visibility, allowing leaders to track shipments and disruptions in real-time. Digital collaboration tools further strengthen supply chain resilience by fostering immediate connections with suppliers at every tier, keeping projects on track despite challenges.

Cost Overruns and Delays

Irrespective of location, delayed suppliers result in considerable cost overruns, with procurement teams forced to react to missed deadlines or inadequate materials. When deliveries arrive late, the entire project can suffer with budget overruns and missed deadlines.

Including contract penalty clauses for delays provides a straightforward approach to help reduce financial liability. Digital tools such as ProQsmart make this possible by connecting procurement with budget and reducing unnecessary workflows, enabling projects to progress efficiently and affordably on time.

Quality Control Issues

Quality control issues in construction are multifaceted and critical to ensuring the safety, durability, and regulatory compliance of projects. These issues can be categorized into structural quality problems, material quality issues, and process-related challenges. Poor material selection, inadequate quality control during production, and improper assembly of components are common concerns. Additionally, lack of transparency in the supply chain, including subcontractor mishandling and supplier failures, can lead to substandard materials that do not meet local or international standards.

Frequent audits and performance evaluations of suppliers are crucial. ProQsmart’s proactive monitoring tools make it easy to provide the ongoing visibility needed to ensure supplier compliance and performance.

Importance of Supplier Management in Construction

Supplier management is a key foundation to maximize operational success in the construction industry. As we’ve seen, complicated supply chains and interdependencies starkly impact project results. By optimizing supplier relationships and employing a reliable supplier management solution, construction firms can drive cost efficiency, ensure quality, and meet tight project deadlines, fostering long-term business growth.

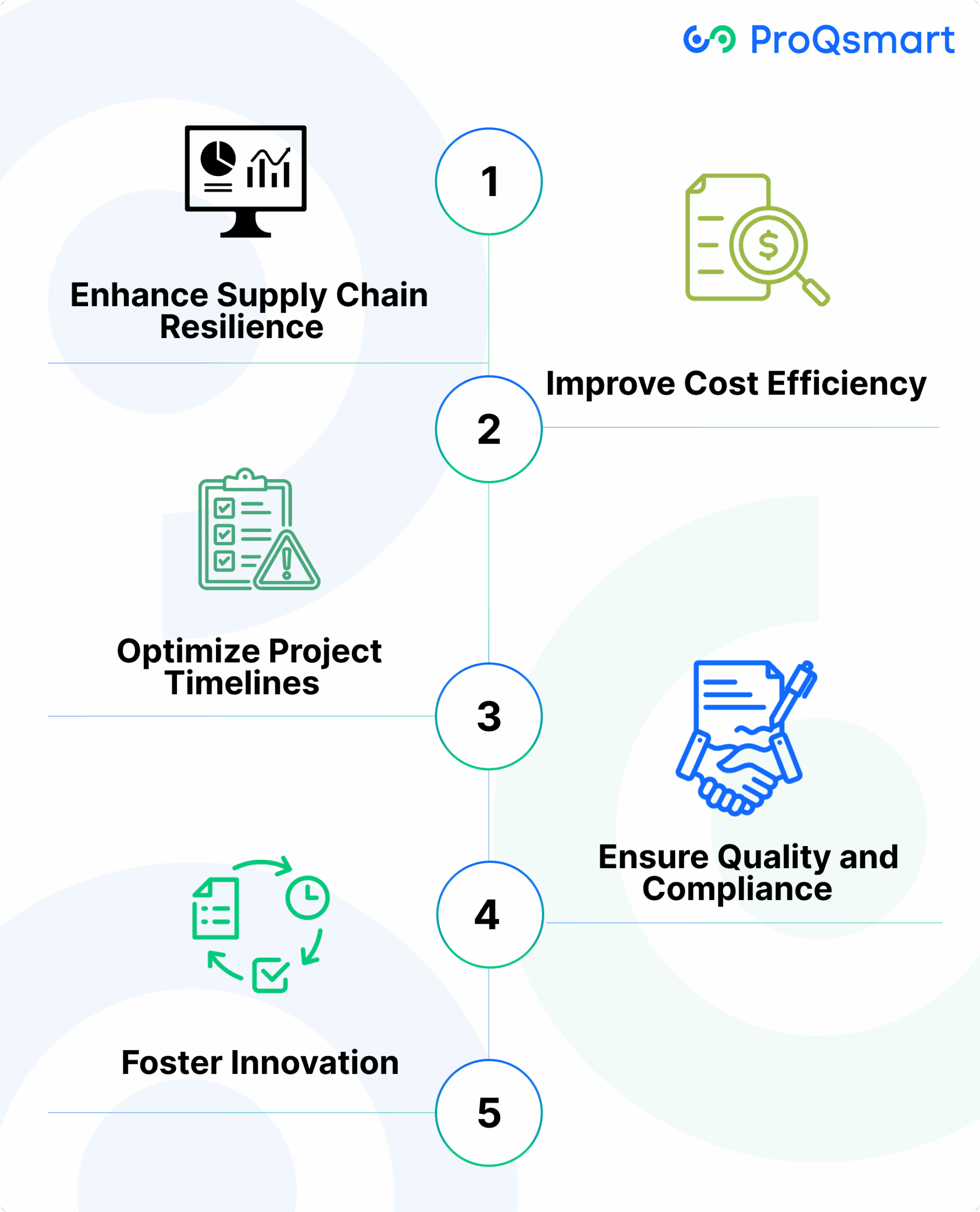

1. Enhance Supply Chain Resilience

Good supplier management strengthens supply chains against unknown future threats by creating an ecosystem of diversified suppliers. Depending on more than one supplier for key resources like steel or concrete helps avoid the dangers of relying on just one source.

Working with suppliers helps increase overall resilience. It helps teams adapt quickly when unforeseen challenges arise, such as shipments being delayed or a shortage of materials. Effective communication with equipment suppliers ensures that vital machinery like cranes and excavators arrive on time.

This foresight avoids dangerous and expensive bottlenecks on construction sites.

2. Improve Cost Efficiency

Streamlined procurement processes and robust negotiation strategies are key to cost savings. Enhanced oversight of supplier performance means not only greater value for taxpayer dollars, like identifying suppliers that repeatedly provide high-quality materials at the lowest responsible costs.

Leveraging platforms like ProQsmart enhances transparency and automates workflows, enabling real-time tracking of expenses and aligning procurement decisions with project budgets.

3. Optimize Project Timelines

Getting suppliers to deliver on time is essential to staying on schedule in the construction world. Construction companies save time and money when clear expectations for delivery are established with ongoing communications if delays are on the horizon.

Documenting supplier policies through tools like ProQsmart simplifies this process, ensuring alignment across all stakeholders.

4. Ensure Quality and Compliance

Routine audits and performance reviews ensure adherence to quality standards in the supplier management process. Metrics like defect rates help evaluate supplier performance metrics, while platforms like ProQsmart provide auditable supplier information for regulatory adherence, further enhancing project integrity.

5. Foster Innovation

Engaging early with key suppliers fosters innovative solutions, whether that means sourcing sustainable materials or advancing more efficient construction techniques. Sharing best practices strengthens supplier relationships and drives continuous improvement, ensuring competitive advantage.

Key Steps for Effective Management

Strong supplier management practices are key to ensuring a reliable supply chain that can quickly pivot as needs evolve. By implementing systematic supplier management processes, businesses can improve supplier performance, promote innovation and collaboration, and drive long-term sustainable growth.

-

Identify potential suppliers through research and referrals.

-

Qualify and select suppliers based on established criteria.

-

Negotiate contract terms to align with business needs.

-

Manage supplier relationships through regular communication.

-

Monitor supplier performance using key metrics.

Identify Potential Suppliers

Informed, comprehensive market research is an essential first step for determining which suppliers best match your business priorities. Tools such as make it easy to maintain accurate, detailed records and speed up this process.

Utilizing your professional network and attending industry/sector related events can uncover more hidden opportunities. At the same time, a diverse supplier base enhances innovation and ignites competition.

Effective segmentation, like grouping your supply community by risk level or total spend, takes sourcing strategies to the next level.

Qualify and Select Suppliers

Qualifying suppliers can include everything from their financial health to reputation to capacity. Equally, operational staff play a crucial role in this process.

This process is aided by undertaking site visits/references to ensure implementation is consistent with operational objectives. A Best Value Sourcing approach, powered by centralized data, strengthens the supplier evaluation process by allowing agencies to make fact-based decisions.

Negotiate Contract Terms

Well-written contracts protect you and your business as well. Adjustable negotiations allow for amendments to meet shifting requirements, and resources such as online contract databases improve adherence and transparency across stakeholders.

ProQsmart takes the guesswork out with tools such as E-tenders and capital expenditure sourcing.

Manage Supplier Relationships

Effective supplier collaboration is built on trust and transparency. Open lines of communication, facilitated through real-time collaboration platforms such as ProQsmart, keep everyone nimble and allow for shared success in supplier relationship management.

Monitor Supplier Performance

Supplier performance should be measured by applicable KPIs, scorecards, and periodic performance reviews, while utilizing effective supplier management solutions. ProQsmart’s performance monitoring tools automate these evaluations to improve reliability and compliance.

Leverage Supplier Management Software

Supplier management software serves as a robust supplier management solution to streamline processes, enhance supplier collaboration, and achieve measurable business outcomes like improved operational budgets and supplier performance metrics. ProQsmart delivers powerful, actionable insights and automation at scale, crucial for businesses aiming for greater transparency, efficiency, and accountability in their supplier relationships.

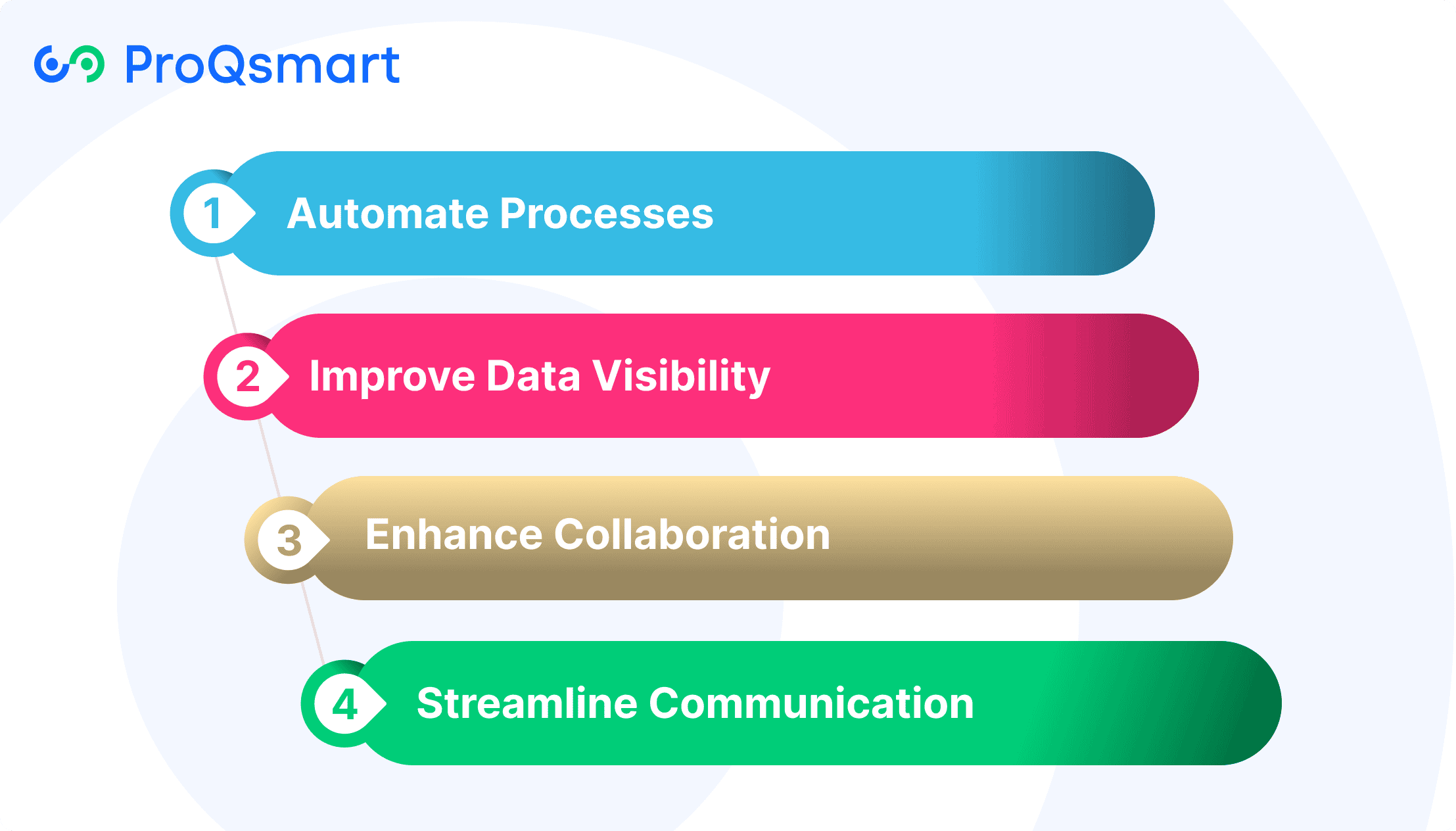

Automate Processes

Automation minimizes manual errors and boosts efficiency by handling repetitive taskslike invoicing, onboarding, and performance tracking. Features such as automated risk monitoring and self-assessment tools reduce administrative burdens and improve vendor data accuracy.

ProQsmart integrates seamlessly with existing systems, ensuring workflows remain uninterrupted while automating crucial processes like subcontractor management and bill of quantities updates. For example, automating supplier onboarding can save time and ensure all compliance documents are accurately recorded.

Improve Data Visibility

Having up-to-the-minute visibility to supplier data allows organizations to make better, more informed decisions while reinforcing supply chain transparency and compliance. ProQsmart centralizes all supplier information and documentation all in one place, providing customizable supplier performance scorecards and valuable predictive insights.

Dashboards and reporting tools provide unprecedented visibility into key metrics like on-time, in-full delivery rates. With the right supplier management software, these rejection rates can increase to an outstanding 98%. This added transparency allows teams to stay one step ahead and manage their supplier relationships more effectively.

Enhance Collaboration

Supplier management software enables increased collaboration by providing tools that connect stakeholders to facilitate real-time communication and collaboration. Add collaborative technology Joint planning and problem-solving catch-up sessions—facilitated by ProQsmart’s agile collaboration suite—help strengthen engagement and hold suppliers publicly accountable to their commitments.

Cloud-based features allow teams to review and approve updates instantly, ensuring alignment across the supply chain.

Streamline Communication

Setting the right expectations and communication standards from day one is key in developing strong supplier relationships. Frequent updates, check-ins, and shared document tools such as ProQsmart’s e-tenders facilitate supplier collaboration, making it easy to keep everything above board and build trust.

Risk Management Strategies

Profitable suppliers—which, by extension, means supplier risk management—is crucial to keeping continuity of operations supply chain management and protecting business profitability. From establishing stronger supplier relationships to enable greater operational resilience, you can achieve more by proactively identifying, mitigating, and responding to potential supplier risks.

Below, we highlight six essential risk management strategies to protect your organization from supplier vulnerabilities.

Identify Potential Risks

Conducting thorough risk assessments is the cornerstone of effective supplier risk management. It’s crucial to evaluate potential vulnerabilities such as financial instability, delivery delays, and cybersecurity threats.

For instance, the SolarWinds attack highlighted the devastating impact of supplier-related IT breaches, with an average cost of $12 million to affected companies. Ongoing risk monitoring enables you to anticipate issues before they escalate.

Leveraging tools like ProQsmart, which assesses supplier performance and monitors risks in real-time, can enhance this process. Such platforms streamline evaluations, aligning with industry recommendations like KPMG’s emphasis on due diligence and NIST’s cybersecurity guidelines.

Develop Mitigation Plans

Then, develop robust mitigation strategies, including identifying relevant contingency actions to respond to known risks. For instance, if a key supplier might go out of business tomorrow, diversifying your supplier base today or lining up alternative suppliers can help avoid dependency.

Collaboration is essential—engaging collaboratively directly with key suppliers to jointly develop risk mitigation plans builds a stronger partnership and trust and creates buy-in and alignment.

ProQsmart’s AI-driven insights make it easy to cut through the noise and automate workflows, with real-time collaboration features keeping your team prepared, no matter what comes your way.

Monitor and Respond to Risks

As new risks arise, the ability to do continuous monitoring will be crucial. Supplier performance reviews, ones that can easily be made with insights provided through platforms like ProQsmart, enable proactive course corrections.

By keeping communication open during risk events, firms maintain transparency and protect relationships. When problems occur, rapid response with previously developed emergency action plans reduces service interruption and restores supply chain continuity.

Foster Communication and Collaboration

Strong communication and collaboration practices are at the core of successful supplier management. Foster a culture of open communication and collaborative teamwork with your vendors. This collaborative process deepens interagency relationships and keeps everyone moving in the same direction toward common goals.

When you place a premium on open communication and establishing trust, you position yourself to build advantageous partnerships that drive mutual benefit and sustainable success.

Establish Clear Communication Channels

Establishing consistent communication channels is key for maintaining supplier awareness and involvement. Centralized platforms where updates, status reports, and other relevant documents can be easily exchanged should be standard operating practice.

This is where the tech comes in. Innovative tools such as electronic data interchange (EDI) and ProQsmart make real-time API data sharing possible, providing every stakeholder with the most accurate, up-to-date information possible.

ProQsmart’s supplier relationships and collaboration features provide your organization with unparalleled transparency, automating workflows to eliminate days of work to save time. Routine communication, like weekly progress reports or milestone presentations, keeps everyone on the same page and prevents problems from sneaking up and sideways on the team.

Encourage Open Dialogue

Building a culture that encourages and enables honest conversations between suppliers and project teams is critical. Suppliers need to see that they can raise red flags or provide honest feedback without fear of reprisal.

Monthly, quarterly, and annual performance reviews will help ensure that this becomes routine. Facilitate quarterly check-ins, allowing space for both sides to address successes, struggles, and things that need more focus.

External feedback not only builds accountability but helps improve outside stakeholder trust, helping make processes sharper on a regular basis.

Build Strong Relationships

Investing in supplier relationships comes with a massive return on that investment. Valuing their contributions via financial incentives or with public recognition is a sure way to build loyalty.

Consistent communication and a strong history of follow-through foster resilience and trust, the bedrock of long-lasting partnerships. Tools such as ProQsmart’s supplier performance monitoring help organizations proactively manage relationships to maintain productivity and alignment with long-term goals.

Conclusion

Effective supplier management ensures continued high-quality operations and cultivates long-term relationships with suppliers. When you take a proactive approach, you lower risks, save money, and increase effectiveness. In the world of construction, where deadlines and budgets are of utmost importance, dependable suppliers maintain constant productivity and high-quality performance.

Using tools such as supplier management software reduces the complexities and makes it easier. These tools ensure compliance, improve performance, identify risks and issues, and facilitate stakeholder communication. Excellent communication builds confidence and addresses issues early before they escalate. Working collaboratively helps keep projects moving while building relationships.

Whatever step you’re taking in the right direction with supplier management positively affects your business. Improved supplier management processes lead to more enhanced, productive and successful impacts. Begin implementing these strategies now to ensure success and maintain your competitive edge. The bottom line small steps taken today can add up to major accomplishments in the future. We’re in this together—it’s time to start building smarter, together.