Supplier performance gaps, such as delayed deliveries, substandard materials, or misaligned communication, pose significant challenges for construction, manufacturing, interior fit-out, and hospitality projects. These issues can increase costs by 15-20%, disrupt schedules, and strain client relationships, leaving procurement teams scrambling to maintain project momentum. Traditional supplier management methods often lack the transparency and agility needed to address these gaps effectively. Supplier Relationship Management (SRM) within e-sourcing platforms offers a robust solution by enabling real-time performance monitoring, data-driven supplier evaluations, and streamlined collaboration to ensure consistent delivery. This article explores the causes of supplier performance gaps and provides practical strategies for leveraging SRM to enhance reliability, control costs, and keep projects on track.

Understanding Supplier Performance Gaps in Procurement

Supplier performance gaps on construction projects can significantly impact operational efficiency when suppliers are late with deliveries, provide materials that don’t meet quality standards, or fail to adhere to established specifications. These issues are common, especially for procurement professionals managing thousands of suppliers, where procurement spend constitutes over 50% of all business costs. Implementing effective supplier management solutions, including defining metrics and utilizing monitoring tools for periodic reviews, is essential to identify these gaps early.

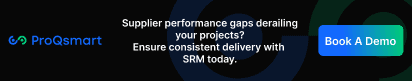

Delayed Deliveries Disrupt Project Timelines

Late deliveries wreck project schedules and increase costs. When required materials don’t show up, as scheduled, crews can halt work, resulting in wasted labor and missed milestones. Projects can be over budget due to additional storage, expedited shipping, or fees.

Most delays are due to bad communication, or inventory control, or supplier capacity issues. Occasionally, suppliers miscalculate lead time or do not risk-flag up-front. A team that depends on a single supplier for critical resources is exposed to greater hazards when that supplier underperforms.

To minimize the risk, establish explicit delivery timelines at the contract phase and maintain open communication channels with suppliers. Use performance metrics to monitor on-time delivery. Add backup suppliers to prevent single-source risk. Hold quarterly check-ins to review delivery issues and do quick fixes.

Quality Inconsistencies Compromise Outcomes

Quality failures create rework, waste, and unhappy clients. When products don’t meet project specs, it can lead to expensive delays or safety hazards. This damages a company’s reputation and can result in lost sales.

Embed quality gates at every step. Leverage industry benchmarks, spec, and test samples prior to delivery. Conduct supplier audits to ensure they maintain required standards. Leverage on-site team input to identify problems quickly and transmit findings to suppliers.

Repair issues with a feedback loop. When a defect is identified, communicate it to the supplier, collaborate on a solution, and verify that subsequent batches comply with specifications.

Poor Supplier Communication Creates Bottlenecks

Poor supplier communication stalls advancement. Groups can overlook significant information, causing mix-up or redundant effort. Information gaps can make both sides miss deadlines or misestimate project requirements.

Project teams can correct this with frequent calls or meetings to exchange status updates. Emails, project management tools, or messaging apps keep everyone on the same page. Problems can be highlighted and monitored so that it doesn’t slip through the cracks.

Establish guidelines for how and when to escalate problems. Provide teams a direct route for rapid escalation if an issue could delay the work.

How SRM Addresses Supplier Performance Challenges

It moves the conversation from a transactional, one-way approach to a collaborative, two-way relationship, incorporating effective supplier management solutions such as real-time tracking and automated scorecards. With supplier management processes, enterprises can identify problems proactively and collaborate to achieve project and sustainability objectives.

Setting Clear Performance Metrics

SRM teams monitor performance through metrics such as on-time delivery, quality compliance, and the timeliness of issue resolution.

They define targets for each metric—whether that’s 98% on-time delivery or <2% defect—to provide suppliers with a benchmark. Periodic reviews, such as monthly or quarterly, assist in evaluating tendencies and identifying issues. This builds accountability and keeps the communications channels open, allowing firms to address issues before they fester.

Enabling Real-Time Performance Monitoring

The best SRM platforms offer automated alerts, dashboard analytics and supplier scorecards that provide real-time information on supplier performance. For example, systems such as ProQsmart link real-time tracking with automated workflows and compliance checks, making performance gaps easier to spot.

To begin with, teams identify KPIs, integrate tracking tools to existing systems, and train personnel. The trick is in actually maintaining the data and keeping the suppliers involved. Overcoming these challenges may include periodic data cleansing, supplier onboarding initiatives and robust IT support. With real-time insights, firms can respond to missed targets or compliance lapses quickly.

Scheduled performance reviews — monthly, quarterly or yearly — are critical for monitoring contract performance and refining targets.

Strengthening Supplier Collaboration

Robust SRM promotes transparent cooperation via frequent communication, mutual planning and feedback mechanisms. Structured events such as quarterly business reviews, innovation workshops and planning meetings allow both parties to exchange updates and align on project requirements.

Supplier performance reviews allow you to talk through successes and challenges, building trust and a mutual desire to improve. Defined expectations and common objectives — whether it’s a sustainability goal or a delivery date — keep everyone aligned. Features in e-sourcing solutions simplify the sharing of real-time status and documents, facilitating collaborative decisions and quicker issue resolution.

The Role of Automated Supplier Scorecards

Automated scorecards provide a standardized method of scoring performance on contract terms and ESG metrics. They assist in diagnosing weak points, demonstrate where help is required, and convey expectations to suppliers.

Scorecards make reporting more transparent and easier to audit, helping to meet compliance needs and build trust with stakeholders.

How to Leverage E-Sourcing for SRM Success

Supplier performance gaps can stall construction projects and increase operational costs. Modern procurement requires effective supplier management solutions to keep projects on track and budgets aligned. E-sourcing is the secret—it offers real-time tracking and monitoring tools, enhancing collaboration and contributing to robust supplier management processes. The table below illustrates the difference between e-sourcing and old school procurement for SRM.

|

Features |

Traditional Procurement |

E-Sourcing (Digital) |

|

Data Visibility |

Limited, slow updates |

Real-time, centralized |

|

Performance Tracking |

Manual, error-prone |

Automated, accurate |

|

Communication |

Fragmented, slow |

Streamlined, instant |

|

Compliance |

Reactive |

Proactive, auditable |

|

Cost Control |

Hard to measure |

Transparent, real-time |

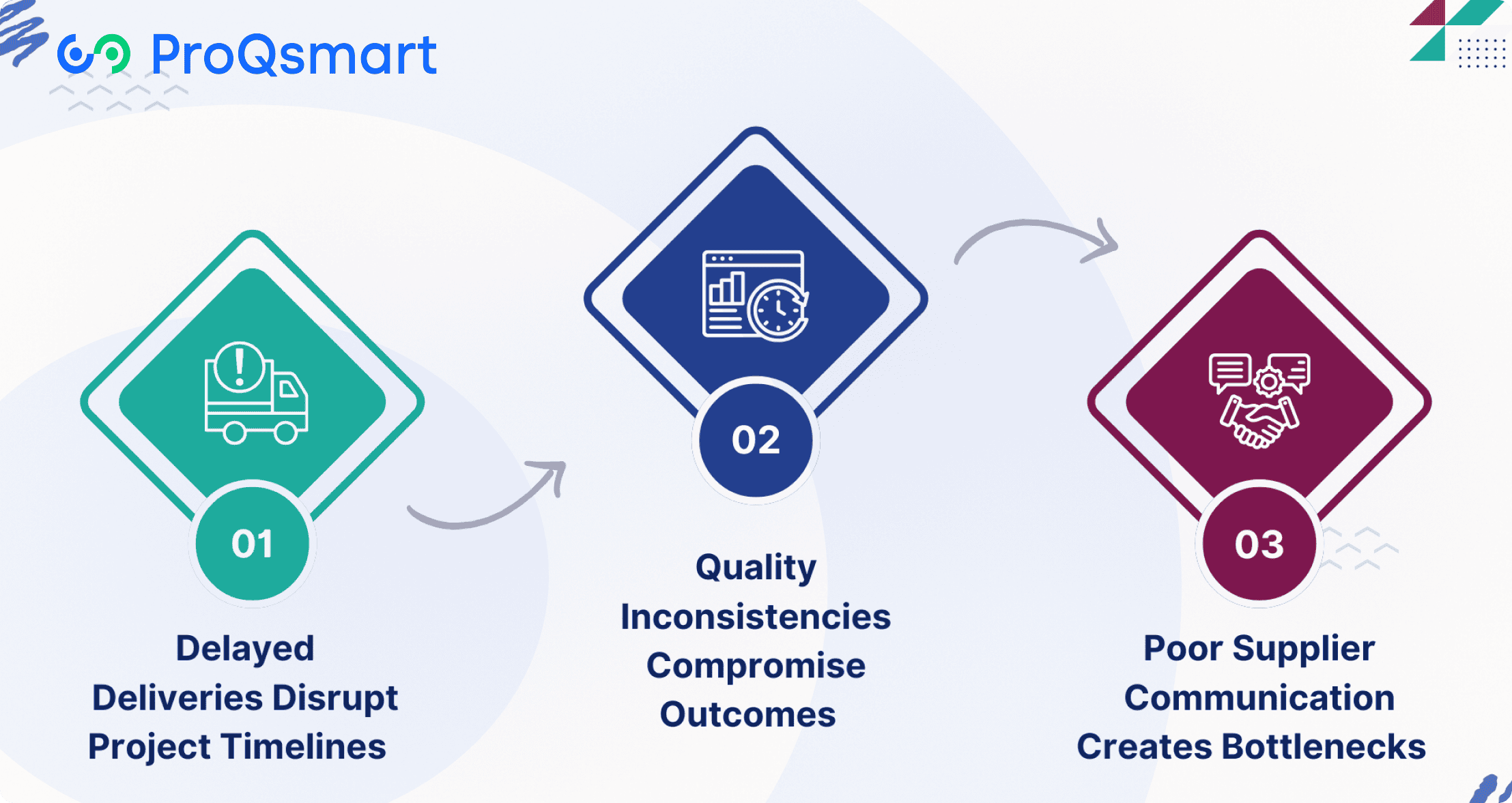

Centralizing Supplier Data for Visibility

Centralizing supplier information facilitates fast decisions, transparent communication and reduced paperwork. It allows teams to view all supplier data in one place. Easy tracking, for example, of on-time deliveries and contract terms. Excellent systems display updates in real-time, feature intuitive dashboards, and integrate seamlessly with other e-sourcing solutions.

Begin by evaluating where all your supplier information resides–spreadsheets, e-mails or legacy databases. Select software that includes easy to use tools such as real-time updates and dashboards. The ProQsmart platform is one tool that brings supplier records, spending, and contract info together, making it simple for teams to work together. Training is key; train teams to use these tools so they fit into daily work.

Automating Performance Tracking and Alerts

Automation in performance tracking reduces errors and provides timely updates. Teams spend less time on manual checking, paving the way for actual work. These alerts can highlight late shipments or missed quality marks before they damage the project.

Configure alerts for KPI’s such as delivery times, cost overruns or quality fails. Select e-sourcing technology with customizable dashboards to fit your needs and pull in data from other systems. These should integrate with email or mobile alerts so the appropriate folks move quickly.

Automated platforms—like ProQsmart—help alert those gaps early. They provide a concise history, facilitating annual supplier evaluations and strategic partnerships.

Mitigating Risks with Predictive Insights

Predictive tools like trend dashboards and real-time analytics enable teams to identify problems before they escalate. They monitor critical measure through multiple tasks.

Teams should apply analytics to observe trends of late orders or quality decline over months. Establishing KPIs for each supplier—such as defect rates or reaction speed—simplifies the process of aligning them to project objectives. Open, routine discussions with suppliers keep everyone aligned and develop trust.

Good SRM reduces risks and keeps projects going smoothly. Procurement leaders leverage these insights for forward planning and to hit hard deadlines.

How to Build Resilient Supplier Relationships

Close supplier relationships are essential for effective supplier management in construction projects, helping to avoid performance gaps and delays. Such connections depend on frank communication, common goals, and frequent feedback, ensuring supply chain management is streamlined.

Align Suppliers with Project Goals

The keys to get suppliers on the same track involve establishing open communication from day one. Which means sharing updates and feedback in real time, so both sides know where things stand.

Establishing common goals that align the project’s requirements with the supplier’s capabilities optimizes collaboration on both ends. When both know where we’re going, it’s easier to solve problems and identify risks early.

Periodic reviews — whether in the form of weekly reports or in-person reviews — enable teams to understand if suppliers are meeting goals. This provides an opportunity to address minor issues before they become major. These checks at fixed intervals develop a culture of transparent conversation and keep all parties accountable around progress.

|

Method |

Speed |

Ease of Use |

Impact on Results |

|

Weekly Calls |

Medium |

Easy |

Good |

|

Written Reports |

Slow |

Simple |

Fair |

|

Face-to-Face Reviews |

Fast |

Hard |

High |

|

Shared Online Dashboards |

Fast |

Medium |

High |

Foster Trust Through Transparency

Trust builds as teams communicate project schedules and expectations to suppliers. This eliminates guesswork and allows both parties to plan in advance.

Filling suppliers in on new project news — like wins or changes — keeps them engaged. It assists them in adapting their efforts or raising concerns prior to them becoming major.

Inviting suppliers’ feedback on what’s tough or going well fosters respect. It demonstrates that their contribution counts and provides purchasers fresh inspiration to resolve age-old dilemmas.

|

Transparency Practice |

Supplier Response |

Project Risk |

Collaboration Level |

|

Open Timeline Sharing |

High |

Low |

Strong |

|

Closed Communication |

Low |

High |

Weak |

|

Feedback Sessions |

Medium |

Medium |

Medium |

Ensuring Long-Term Supplier Relationship Stability

Robust supplier management drives resiliency, enhances quality, and maintains project momentum. Effective supplier management solutions focus on communication, performance, and risk management, all key to long-term success.

Diversifying Supplier Networks

A diverse supplier network begins with mapping your current suppliers and pinpointing where your business is dependent on key suppliers. Teams need to think local and global, seeking specialized suppliers with rare expertise and collaborating with providers abroad. This strategy diversifies risk and enhances supply chain resilience by providing access to additional resources and knowledge.

Establishing a broad-based supplier base minimizes schedule disruptions caused by one-provider glitches. It contributes to operational efficiency and cost control. For instance, sourcing steel from local mills as well as international producers ensures a stable supply when market conditions change.

Evaluating prospective suppliers involves verifying their reputation, quality assurance processes, and timeliness. Teams often assess certifications, previous project results, and the cultural fit between a supplier’s values and project objectives, which is crucial for effective supplier management.

A checklist for managing diverse suppliers could include monitoring tools for supplier performance metrics and ensuring compliance with industry standards.

-

Monthly check-ins

-

Joint planning sessions

-

Regular performance reviews

-

Collaboration on process improvements

Integrating Sustainability into SRM

Sustainability is now part of supplier management. Companies need to check each supplier’s environmental policies and their utilization of recycled or eco-friendly materials. Working exclusively with green suppliers addresses the needs of both clients and regulators.

Continuous auditing is key. These verify whether suppliers adhere to their green commitments — from waste disposal to energy consumption and emission levels. For instance, a contractor may exclusively utilize concrete suppliers that monitor their carbon footprints.

|

Traditional SRM |

Sustainable SRM |

|

Focus on price & delivery |

Adds environmental compliance |

|

One-way performance checks |

Regular two-way feedback |

|

Limited supplier data |

Full transparency, live metrics |

Conclusion

Effective supplier relationships are critical for maintaining project timelines, controlling costs, and ensuring consistent delivery in construction, manufacturing, interior fit-out, and hospitality industries. Supplier performance gaps, if left unaddressed, can escalate into costly delays and quality issues. Supplier Relationship Management (SRM) within e-sourcing platforms mitigates these risks by providing real-time performance tracking, transparent communication, and data-driven supplier evaluations. By leveraging SRM tools, procurement teams can proactively address gaps, align suppliers with project goals, and foster long-term partnerships that drive efficiency and reliability. As the industry demands greater accountability and precision, e-sourcing with SRM offers a strategic advantage for seamless project execution. Ready to enhance your supplier management and keep projects on track? Book a demo with ProQsmart today to explore how e-sourcing can transform your procurement strategy.