Supplier Performance Management (SPM) is a critical component of strategic procurement that focuses on assessing, monitoring, and improving the performance of suppliers. SPM aims to ensure that suppliers meet or exceed the agreed standards and contribute positively to the business’s objectives. In this blog, we will delve into what SPM entails and how businesses can effectively implement it.

Understanding Supplier Performance Management

SPM is about creating a systematic approach to evaluating supplier contributions to your business. It involves setting performance criteria, monitoring suppliers against these benchmarks, and fostering continuous improvement. The goal is to develop a mutually beneficial relationship where both parties thrive.

The Importance of SPM

Effective SPM can lead to:

- Improved product quality and service delivery

- Enhanced supplier reliability and risk management

- Cost reductions and value optimization

- Strengthened supplier relationships and collaboration

How to Implement Supplier Performance Management

Define Performance Metrics: Establish clear, quantifiable metrics that align with your business goals. Common metrics include delivery timeliness, quality standards, cost management, and innovation contributions.

Regular Performance Evaluations: Conduct periodic assessments of supplier performance using the defined metrics. This could involve audits, performance reviews, and feedback sessions.

Communication and Feedback: Maintain open lines of communication with suppliers. Regular feedback helps address issues proactively and reinforces positive performance.

Collaborative Improvement Plans: Work with suppliers to develop action plans for addressing any performance gaps. This collaboration can lead to process enhancements and stronger partnerships.

Leverage Technology: Utilize SPM software tools to track performance data, automate evaluations, and gain insights into supplier interactions. This can streamline the SPM process and provide a more comprehensive view of supplier performance.

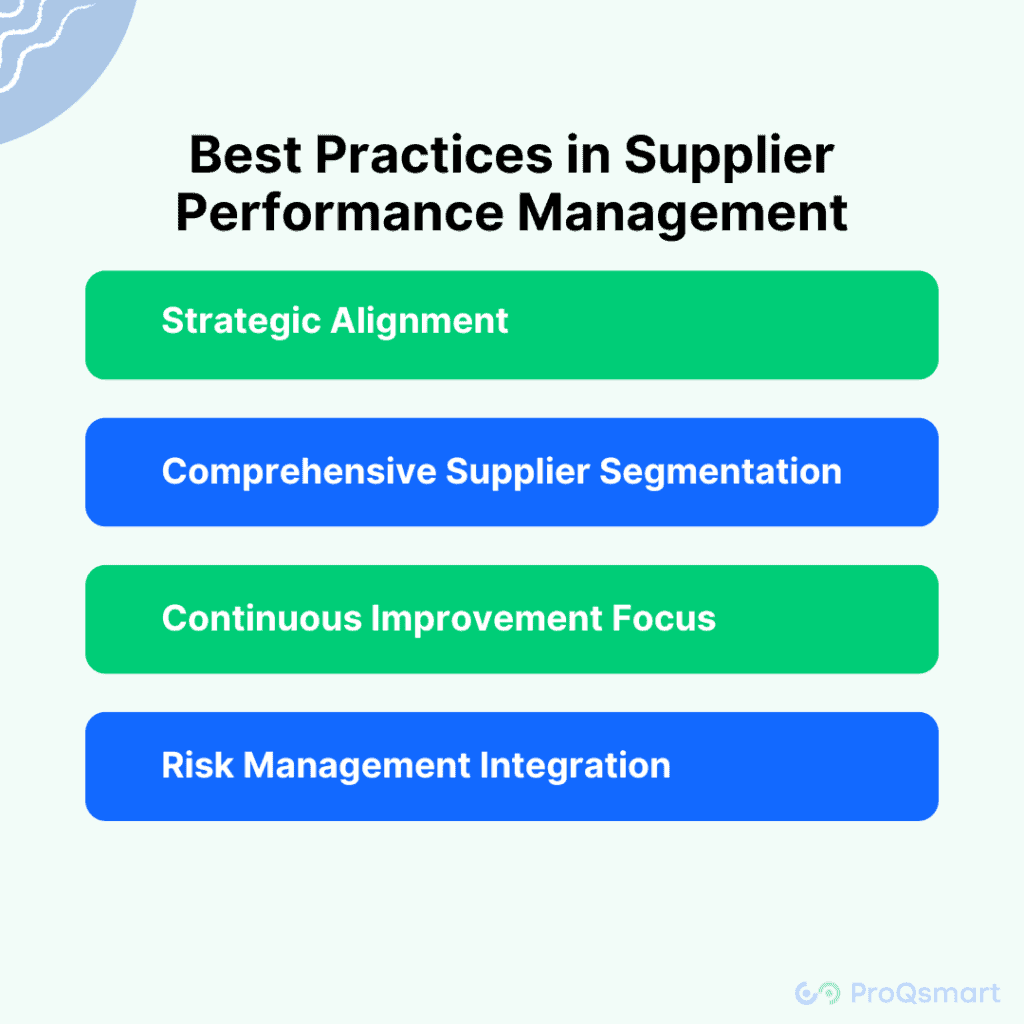

Best Practices in Supplier Performance Management

Strategic Alignment

Ensure that SPM objectives align with your overall business strategy. This coherence ensures that supplier performance directly contributes to achieving business goals.

Comprehensive Supplier Segmentation

Not all suppliers are the same. Segment them based on their importance to your business and customize the management approach accordingly.

Continuous Improvement Focus

SPM should be a dynamic process. Encourage continuous improvement and innovation from your suppliers to drive long-term success.

Risk Management Integration

Incorporate risk assessment into your SPM process to identify and mitigate potential issues early on.

The Role of SPM in Business Success

SPM is not just a procurement function; it’s a strategic business enabler. By effectively managing supplier performance, businesses can ensure a reliable supply chain, foster innovation, and maintain competitive advantage. It’s about building relationships that drive mutual growth and success.

Conclusion

Supplier Performance Management is a vital strategy that goes beyond mere supplier monitoring. It’s about fostering a productive partnership that aligns with business objectives. Implementing an effective SPM program requires clear metrics, regular assessment, collaborative improvement, and the right technology support. By prioritizing SPM, businesses can optimize their supplier relationships, enhance operational efficiency, and achieve strategic goals, paving the way for sustained business success.