Supplier performance management is the process of evaluating and monitoring suppliers to keep them in line with your organization’s standards in quality, delivery, cost, and compliance.

In doing so, by consistently monitoring and evaluating supplier performance, you can minimize risks, make your supply chain more efficient, and enjoy significant cost savings. It’s about utilizing data-driven metrics, consistent communication, and proactive collaboration to ensure high-value supplier relationships.

Good supplier performance management extends beyond operational goals, ensuring that procurement practices align with broader business objectives, including sustainability and innovation. Whether managing a small set of critical suppliers or a large, diverse supplier ecosystem, a methodical approach helps address challenges such as varying performance levels and regulatory requirements more effectively.

In this article, we will explore a step-by-step guide to supplier performance management, focusing on best practices, advanced strategies, and the role of technology in optimizing supplier relationships for strategic sourcing success.

What Is Supplier Performance Management?

Supplier Performance Management (SPM) is a methodical process designed to assess, monitor, and improve the contributions of suppliers to a business. It involves evaluating suppliers based on specific metrics and key performance indicators (KPIs) such as quality, cost, and delivery timelines. This supplier performance management process ensures that suppliers meet the agreed-upon expectations while supporting the operational goals of the organization.

By consistently tracking performance using supplier performance management software, businesses can identify strengths, address weaknesses, and create a framework for long-term collaboration. SPM is essential to realizing operational efficiency. By analyzing relevant supplier performance data and aligning outputs with predefined benchmarks, businesses can optimize inventory levels, minimize excess stock, and reduce stockout risks.

For example, ongoing tracking may indicate trends in late shipments, so companies can work with suppliers to prevent these problems before they occur. This proactive approach helps maintain a handle on costs and ensures timely delivery of products to customers, ultimately increasing customer satisfaction.

Difference Between SRM and SPM

Understanding the distinction between Supplier Relationship Management (SRM) and successful supplier performance management (SPM) is crucial for effective supply chain operations. By recognizing these differences, organizations can leverage both approaches to optimize supplier performance data and relationships.

|

Aspect |

Supplier Relationship Management (SRM) |

Supplier Performance Management (SPM) |

|---|---|---|

|

Focus |

Building strategic partnerships, fostering collaboration, and driving mutual value creation. |

Monitoring and evaluating supplier performance against predefined metrics. |

|

Goals |

Long-term partnerships, innovation, and mutual growth. |

Ensuring suppliers meet contractual obligations, minimizing risks, and optimizing performance. |

|

Approach |

Strategic, emphasizing collaboration and trust. |

Tactical, focusing on measurable criteria and accountability. |

|

Key Activities |

Joint planning sessions, innovation workshops, and regular communication. |

Performance tracking, scorecards, and corrective action plans. |

|

Benefits |

Sustainable value creation, enhanced collaboration, and strategic alignment. |

Improved efficiency, reduced risks, and cost savings through optimized performance. |

|

Tools and Platforms |

Platforms like ProQsmart support SRM by facilitating collaboration and relationship-building. |

ProQsmart also supports SPM by streamlining performance reviews and ensuring contract compliance. |

Phases of Supplier Performance Management

Supplier performance management (SPM) is a highly effective, systematic practice that serves as a strategic tool for successful supplier performance management. Its aim should be to drive and reward suppliers to consistently deliver above and beyond the standards required to achieve business goals. This multi-phase, iterative process functions together to create a cycle of continuous improvement, essential for effective supply chain operations.

By addressing each phase of the supplier performance management process, organizations can mitigate risks and save taxpayer dollars. This approach allows them to sidestep the subpar quality often linked to poor supplier performance, targeting failures and compliance risks. The iterative nature of the process ensures that suppliers are consistently monitored and optimized for greater performance.

- Setting expectations

- Monitoring performance

- Providing feedback

- Driving improvement

Utilizing comprehensive supplier performance management solutions, businesses can enhance their supplier relationships and maintain a quality supplier base. By focusing on specific performance metrics, organizations can ensure that their suppliers are always under review, fostering a culture of ongoing supplier performance management that leads to improved operational outcomes.

Setting Clear Performance Expectations

The secret to successful SPM starts with setting the right performance standards. Suppliers require a clear idea of what’s expected of them, whether that’s quality requirements or deadlines for delivery. For instance, setting KPI definitions such as On-Time Delivery or Lead Time always ties them back to the objectives of the business.

Written agreements express these expectations, help avoid ambiguity, and create accountability. Replacing old performance metrics with new ones that support changing needs helps ensure our suppliers can continue to be flexible to the market.

Monitoring and Evaluating Supplier Performance

A structured approach to monitoring allows businesses to track progress efficiently. Performance dashboards offer a visual representation of metrics such as DIFOT or Average Delay, providing actionable insights. Regular evaluations, whether monthly or quarterly, ensure benchmarks are met consistently.

These assessments, supported by documented findings, inform long-term supplier strategies and help identify both opportunities for improvement and top-performing suppliers.

Providing Feedback and Driving Improvement

Constructive feedback is essential for growth. Approaches such as formal performance reviews, scorecard systems, and even informal conversations can raise suppliers’ awareness and alert them to problems with their performance.

Collaborating on improvement plans encourages shared success, and acknowledging accomplishments helps build stronger relationships. With ProQsmart’s smart supplier performance monitoring feature, you can simplify these processes with real-time evaluations and insightful overviews.

With its automation capabilities, you can deliver timely, consistent, data-driven feedback to maximize outcomes.

Key Metrics for Measuring Supplier Performance

Smart supplier performance management starts with measuring the right metrics. These detailed metric sets assist in evaluating suppliers performance on the achievement of organizational goals.

These metrics provide a comprehensive view of supplier performance, including quality, delivery, cost efficiency, risk management, innovation, and sustainability. By customizing these metrics based on industry and supplier context, businesses can make sure that evaluations are targeted and impactful.

Continuously reviewing the relevance of these metrics helps keep the focus on what’s most important to meet changing business goals, leading to improved decision-making and increased operational efficiency.

|

Category |

Key Metrics |

|---|---|

|

Quality |

Defect Rate, Compliance Rate, Quality Control Reports |

|

Delivery |

On-Time Delivery Rate, Delivery Accuracy, Shipment Timeliness |

|

Cost |

Total Cost of Ownership, Procurement Costs, Pricing Structures |

|

Risk |

Supplier Risk Score, Operational Risk Management, Contingency Plans |

|

Innovation |

Number of Innovative Solutions, Responsiveness to Market Changes, Collaborative Efforts |

|

Sustainability |

ESG Alignment, Ethical Practices, Progress in Sustainable Sourcing |

Quality and Compliance Standards

Setting clear quality standards is vital to upholding product integrity and quality assurance. Metrics such as the defect rate are obvious, quantifiable measures.

If your defect rate is 4%, that means 200 out of 5,000 units delivered are defective. A defect rate above 15% indicates systemic problems that must be addressed urgently.

Compliance checks help ensure that industry regulations and contracts are strictly followed. Consistent quality control reports draw attention to supplier performance and allow for swift remedial actions in cases of poor quality.

Delivery Timeliness and Accuracy

On-time delivery performance is crucial for the operational heartbeat. Supplier reliability can be measured by metrics like on-time delivery rate.

A low rate, like 70%, raises red flags. Measuring shipment accuracy helps you know if orders are being delivered to spec, and repeated delays require you to establish communication and resolution before the fact.

Easy-to-understand accountability measures, such as setting clear consequences for continued non-compliance, help drive supplier engagement.

Cost Efficiency and Value

Analyzing procurement costs provides a unique perspective into the financial implications of supplier relationships. Total cost of ownership goes beyond just a purchase price, including expenses such as maintenance and long-term lifecycle costs.

Incentivizing suppliers to suggest cost-saving initiatives that don’t affect quality further enhances value. Timely pricing reviews protect your competitiveness while making sure the supplier is cost-effective.

Risk Mitigation and Management

Knowing where the risks might lie is key. A supplier risk score, calculated based on factors such as a supplier’s financial health and geopolitical risks, measures exposure levels.

By strengthening supplier capabilities to anticipate and manage risks, and having contingency plans in place if they don’t, you can minimize disruption. Consistent review of different risk strategies allows companies to tailor operations to changing market conditions and build resilience.

Innovation and Responsiveness

Suppliers are integral to innovation. Additional metrics such as contributions toward the development of innovative solutions measure the creativity of the suppliers.

Ability to respond to changing specs or market demand is crucial. The ability to pivot quickly is indicative of an agile supplier. Innovation thrives in a collaborative environment, and rewarding the best performers inspires others to work harder and smarter.

Sustainability and Ethical Practices

These sustainability metrics can help you start to get supplier practices in line with your ESG goals. Ethical standards and environmental compliance evaluations help make sure that your materials are responsibly sourced.

Incentivizing suppliers to adopt practices that minimize their environmental impact leads to more widespread corporate social responsibility. Consistent, metric-based tracking of sustainable progress leads to significant and impactful change, to the advantage of both the organization and the overall community.

ProQsmart powers these initiatives by automating supplier performance monitoring, guaranteeing compliance, and encouraging collaboration, fueling transparency and efficiency.

Managing Underperforming Suppliers Effectively

In order to manage underperforming suppliers effectively, your organization needs a defined and deliberate process to address performance issues quickly and effectively. Through an approach rooted in collaboration, transparency, and accountability, procurement professionals can improve dynamic supplier relations while improving procurement overall.

Here, we examine critical strategies for managing underperforming suppliers to achieve best-in-class outcomes.

Maintain Transparent Communication

Clear, open, and frequent communication is the key to bridging the performance gap. When you build a culture of trust and accountability, you open the door to an environment where suppliers can be forthright about challenges.

Build a culture of accountability by encouraging suppliers to voice concerns and keep communication clear and effective with tools such as ProQsmart that promote real-time collaboration and improve transparency. Open, transparent communication throughout the process will help set expectations around performance objectives and create an environment conducive to developing long-term relationships.

Collaborate on Problem-Solving Strategies

Involving suppliers in collaborative problem-solving processes fosters a culture of continuous improvement and accountability, often resulting in novel solutions to challenges. Creating action plans that denote specific steps and who is responsible for each step helps establish commitment to improvement on both sides.

If a supplier’s defect rate is repeatedly causing our production schedules to be thrown off, let’s address the issue collectively. The solution lies in redesigning workflows or reallocating resources.

Utilize ProQsmart’s supplier performance tracking tool to measure year-over-year improvement and pivot 2nd and 3rd tier strategies if not working. Consistently going back to the drawing board on these plans helps problem-solving efforts stay fresh and focused.

Provide Support and Necessary Resources

Most of the time, underperformance is due to a lack of resources or a lack of skills. Providing training or tools to address weaknesses can go a long way to strengthening a supplier’s capabilities.

ProQsmart’s training modules and guided, automated workflows are built to streamline the process, ensuring all suppliers can quickly perform to the standards expected. Help them address their greatest needs—be it for compliance, where to source capital expenditure, or how to manage their subcontractors—and give customized guidance.

Keeping an eye on the results these resources are generating will help guarantee they’re yielding tangible advancements—saving you from expensive rework and protecting your brand reputation.

Offer Regular Feedback and Monitoring

Regular feedback meetings help ensure there are no surprises and that suppliers are working toward performance goals. Conduct quarterly reviews. These will give you opportunities to celebrate successes, discuss areas of concern, and recalibrate strategies.

For other suppliers who maintain a steady level of performance, an annual review should be enough. Formal documentation of these conversations creates a record of accountability and working documentation to refer to while monitoring progress.

Utilize concrete performance metrics such as FPY and defect rates to direct feedback, ensuring that it is focused on actionable insights. By automating the performance review process, ProQsmart simplifies the entire process, allowing you to focus on productive, data-driven conversations.

Use Incentives to Drive Performance

Incentive programs can motivate suppliers to exceed performance targets. Rewards aligned with desired outcomes, such as cost savings or improved quality, encourage active participation.

For example, a supplier achieving a high FPY could qualify for preferred contracts or increased order volumes. Regularly evaluate these programs to ensure they remain effective and beneficial for both parties.

Communicating the tangible benefits of meeting targets fosters engagement and strengthens supplier commitment.

Define Consequences for Non-Compliance

Setting clear penalties for failure to comply underlines the seriousness of these performance standards. Clearly communicate the possible outcomes—including the possibility of contract renegotiation or termination—so that you can hold them accountable.

When non-compliance does happen, it can be a valuable learning experience, showing where there is still room for improvement. With ProQsmart, you’re able to meet regulatory and safety compliance requirements while monitoring supplier performance with actionable, auditable data to back the best decisions.

Ensuring compliance with agreements protects the integrity of the procurement process and reduces risk.

Best Practices in Supplier Performance Management

When done right, supplier performance management can be the foundation of operational excellence and sustained business success. Implement rigorous methods and practical tactics. In this manner, you can ensure that suppliers are held accountable and deliver value beyond the bare minimum.

Here are my best practices to maximize supplier performance management and drive tangible improvements in quality, cost, and collaborative efforts.

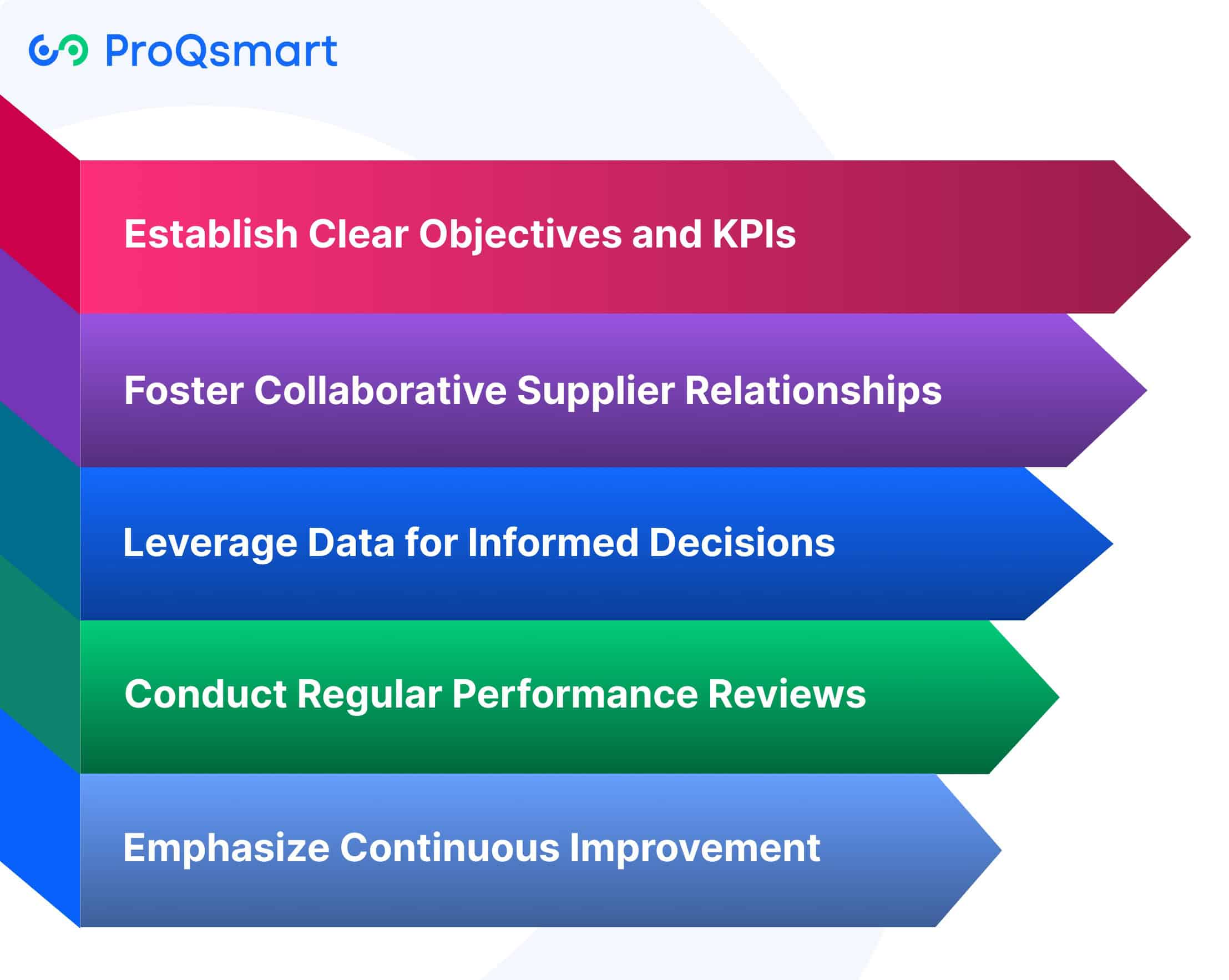

Establish Clear Objectives and KPIs

Setting specific, quantitative, and actionable objectives is crucial to aligning supplier performance to your goals as an organization. Setting clear KPIs such as Defect Rate, Order Accuracy, and Rate of Return increases your capacity to monitor supplier performance.

This step makes you better at managing quality, delivery, cost, and responsiveness. Consistently revisiting these objectives will help keep them fresh and applicable. For instance, Ivalua’s supplier management software makes it easier to monitor compliance by consolidating KPI tracking and performance data in one easy-to-use dashboard.

Foster Collaborative Supplier Relationships

Good partnerships are developed on the basis of mutual trust and ongoing dialogue. While joint problem-solving sessions get to work on important challenges, taking the time to celebrate successes improves morale and motivation.

For example, publicly lauding a supplier for achieving a 98% order accuracy rate will build camaraderie and encourage shared growth between both parties. Long-term collaborations with both public and private sectors help drive innovation and greater efficiencies for both parties.

Leverage Data for Informed Decisions

Data analytics is at the very core of effective supplier management. With historical data, you can identify patterns such as always late deliveries or chronic defects, informing your actions.

Tools, such as ProQsmart’s unified platform, consolidate this data, providing a centralized view of contracts, compliance, and risk profiles. That’s how you make sure awards and decisions are based on the most accurate, fair, and actionable insights possible.

Conduct Regular Performance Reviews

Regular reviews, conducted monthly or quarterly, provide a structured way to evaluate supplier contributions. Including stakeholders in these reviews ensures diverse perspectives.

Documenting outcomes in a centralized system helps track progress and focus on areas needing improvement. For example, reviewing contract compliance rates can highlight suppliers exceeding or falling short of benchmarks.

Emphasize Continuous Improvement

When you encourage suppliers to innovate and adopt efficiencies, it benefits everyone. Share lessons learned and best practices to raise the bar for everyone’s performance.

This proactive approach to improvement, which only 20% of companies have adopted, gives you the edge in reaching supplier excellence.

Role of Technology in Supplier Management

In today’s procurement environment, technology is a key building block to improving supplier performance management. It empowers organizations to move away from the old, reactive ways of doing business to new, smarter, data-driven practices. Companies can make supplier evaluation easier by using technology and integrated platforms.

This modified approach encourages collaboration and helps drive actionable insights that keep people aligned and moving towards bigger operational objectives.

Real-Time Data Analysis for Insights

Real-time data analytics revolutionizes supplier performance management by arming organizations with real-time, actionable insights. ProQsmart’s Supplier Management software brings all data together for you. This further simplifies the process of tracking important metrics such as on-time delivery, quality, and regulatory compliance.

Ongoing tracking makes it easier to spot signs of trouble before they can escalate into serious issues. Data visualization tools help break large, complex datasets into simple, easy-to-understand charts that can aid your organization’s decision making. A data-driven culture incentivizes teams to leverage these insights to optimize supplier strategies, fostering efficiency and accountability.

Automating Performance Tracking Processes

Automation tools streamline the process and reduce human error in tracking progress along the way, creating efficiency and consistency in impactful reporting. Platforms such as ProQsmart intelligently automate workflows, providing easy access to trusted supplier data—and more importantly, the data connects to sourcing and procurement processes.

This helps to make sure that supplier performance metrics are uniformly represented across the procurement lifecycle. Continual review of these tools provides added oversight and operators, freeing up procurement teams to concentrate on chief goals.

Enhancing Collaboration Through Digital Tools

By using digital collaboration tools, buyers can create a stronger bond with their suppliers by building clarity of communication and shared accountability. ProQsmart, for example, offers cloud-based, real-time collaboration tools, making it easier than ever to share documents, give feedback and make updates.

When suppliers are closely engaged in these external launching initiatives, the relationship develops into a partnership. By tracking supplier-customer interactions in real-time, procurement teams can foster positive supplier-customer dynamics over time, strategically maintaining alignment with organizational goals.

Predictive Analytics for Proactive Management

Predictive analytics, fueled by AI, provides industry-leading visibility into supplier performance. By leveraging historical data, procurement teams can have a clearer picture of risks and proactively tackle challenges to mitigate risk.

For instance, ProQsmart’s unified platform leverages predictive models to detect upcoming disruptions, so organizations can take proactive steps to reduce or eliminate risks before they materialize. Frequent re-calibrations keep these models up-to-date and relevant, which is key for organizations looking to navigate rapidly changing market dynamics.

It’s these kinds of insights that will lead to long-term success and stability in your supplier management.

Conclusion

Supplier performance management can create big changes for the better in procurement. It helps you keep suppliers accountable, strengthen partnerships, and lower risks. Having clear metrics and well-researched strategies helps to identify gaps and address them quickly. Second, technology improves your efficiency within supplier performance management by providing you more robust tracking and insights.

The most important part is just to be proactive. Periodic evaluations, clear communication, and a commitment to strategic sourcing help keep your suppliers on the same page as you and with your overall goals. With this approach, you can reduce costs, improve quality, and foster profitable, sustainable growth.

It’s the power of taking small, consistent steps over time that leads to long-term success. Begin with the end in mind, measure the things that truly matter, and use the data to make informed decisions. When you have strong supplier performance, everyone down your whole supply chain wins. It’s the competitive advantage you need to succeed and prosper.

Ready to unlock the full potential of supplier performance management? Book a demo with ProQsmart today to discover how their innovative solutions can streamline your supplier performance management processes, enhance supplier engagement, and empower your team to make better, more strategic decisions.