Supplier Performance Metrics Scorecard is an essential tool for systematically measuring and improving supplier performance. By tracking key factors such as quality, delivery, cost, compliance, and innovation, organizations can quickly identify top-performing suppliers and areas needing improvement.

Beyond simple tracking, scorecards promote transparent communication and collaboration between buyers and suppliers, helping to address challenges, align expectations, and drive continuous improvement. Regular use of scorecards also supports risk management and ensures compliance with regulations and contracts.

In manufacturing and project-driven environments, supplier scorecards help procurement teams benchmark suppliers, reduce waste, control costs, and keep projects on schedule. Over time, this disciplined approach enhances procurement efficiency, strengthens partnerships, and builds a more resilient supply chain.

This article covers the definition, structure, and advanced strategies for using supplier performance scorecards to optimize supplier management and achieve better results.

What Is Supplier Performance Management (SPM)?

Supplier performance management, or SPM, functions as a consistent, ongoing process to review how well suppliers are performing to a business’ needs. SPM sets measurable objectives. This includes monitoring key metrics, including on-time delivery, on-time cost shifts, supplier compliance with contract terms, etc.

Each of these numbers are closely monitored by teams year-round. It’s not simply a one-off task either — they have turned it into a quarterly practice. They use these checks to spot risks early, like a dip in quality or late shipments, that could lead to costly supply problems.

As an example, companies typically spend $100K+ for each supply chain disruption, so consistent monitoring has a tangible impact.

Supplier relationship management (SRM) emphasizes fostering trust and direct communication with suppliers. Supplier performance management (SPM) focuses more on concrete data. Both SPM and SRM are crucial, just in different ways.

SPM heavily depends on different metrics and KPIs, including price changes, business process health, compliance scorecards, etc. Conversely, SRM is about the mutual exchange that builds collaborative relationships. When used in tandem, they not only help teams achieve better prices, but help them create a universe of strong, dependable suppliers.

SPM vs. Supplier Relationship Management (SRM)

Supplier performance management (SPM) uses set goals and data-driven checks, while SRM grows ties with suppliers for shared wins. SPM might use tools like Ivalua to track contract terms and cost impact, while SRM may set up regular meetings to keep both sides in sync.

Both feed off each other: good data from SPM makes SRM talks more open, and strong ties from SRM help fix problems SPM finds.

Strategic Role in Procurement

SPM influences larger business-building decisions by providing transparent documentation of supplier performance over an extended period. That’s what it does — it empowers teams to reduce costs, reduce risk, and protect supply lines from unexpected disruptions.

By looking at objective, real-time scores, they are better able to identify healthy partners and structure contracts that benefit the entire organization.

Why Supplier Metrics Truly Matter

Supplier metrics can be the leading force in how organizations begin to operate their procurement and supply chain functions. They provide an objective, unambiguous yardstick to evaluate supplier performance and allow cross-functional teams to make more informed decisions.

With most procurement teams handling about 3,000 suppliers for every $1 billion they spend, these numbers keep things in line and help teams spot what’s not working. These metrics shine a light on some critical supply chain drivers, like velocity, conformance and reliability.

Using this data, teams can see where to adjust and optimize accordingly. This ensures that whatever initial product quality you’ve established is consistently maintained and it keeps your purchasers satisfied.

Supplier metrics encourage transparency and thoughtful collaboration with suppliers. When data is transparent, suppliers understand their deliverables, and internal teams can more effectively hold them accountable.

This structure incentivizes suppliers to act in the best interest of the company. In the end, it aligns everyone to the same goal. These clear benchmarks allow you to quickly spot a cost overrun or project slowdown.

This helps teams work proactively with suppliers, avoiding problems and ensuring speed to resolution.

Driving Strategic Procurement Decisions

Supplier metrics, such as time delivery rates and quality, directly influence the procurement process when soliciting and selecting vendors. For instance, if a supplier consistently exceeds lead time expectations, procurement managers may choose them to fulfill urgent orders, leveraging their vendor scorecard for negotiation.

These key performance indicators—cost, quality, and delivery—support all contract negotiations and enable teams to negotiate better rates, making the supplier performance scorecard a valuable tool for evaluating vendor relationships and identifying performance gaps.

Optimizing Supply Chain Efficiency

Metrics for things like on-time delivery, fill rates, and defect rates allow teams to identify these chokepoints. If one supplier is going to be late, teams can move work around or adjust timings.

It improves the production pipeline by ensuring that work is consistently moving through each phase, reducing bottlenecks and eliminating late deliveries.

Enhancing Supplier Reliability

Teams track supplier KPIs using a supplier scorecard to ensure suppliers are consistent and define specific goals for what’s considered “good.” Open lines of communication with your suppliers can address miscommunications and mistakes before they damage your vendor relationships.

Mitigating Supply Chain Risks Early

Routine monitoring through supplier scorecarding and relevant KPIs prevents threats from escalating and crossing the tipping point. Operations teams will be better equipped to create contingency plans and have direct conversations with their suppliers on next steps should something go awry.

Fostering Collaboration and Trust

When reporting is open, all teams and suppliers create an atmosphere of trust. Utilizing a supplier scorecard to evaluate performance, teams can recognize when a supplier fixes a problem or achieves top marks, fostering strong vendor relationships.

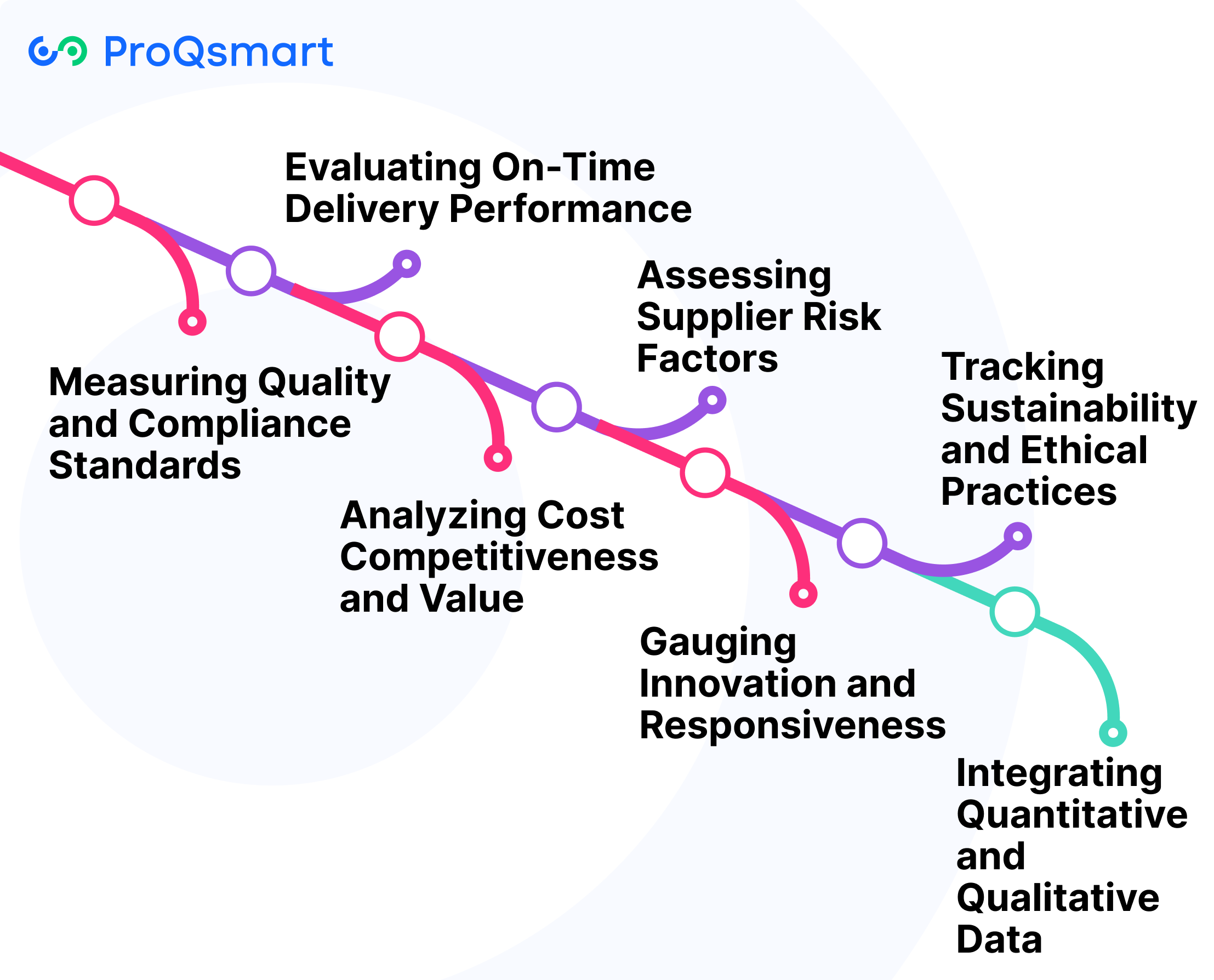

Key Metrics for Supplier Scorecards

Supplier scorecards shine when they’re built around clear and achievable metrics. These six metrics will give you a well-rounded view of supplier performance.

These metrics must connect to the business goals and align with industry benchmarks. By picking the right mix, teams can judge suppliers across cost, quality, delivery, service, and sustainability—making sure all bases are covered.

1. Measuring Quality and Compliance Standards

Quality, specifically defects or nonconformance’s, seems to be one of the most recorded metrics. Defect rate is a go-to number, and it’s the percent of goods received that fail to meet requirements.

This ensures high and even product quality, supporting customer satisfaction. Procurement teams establish benchmarks that align with what the buyers seek and what the industry is prepared to deliver.

Consistent monitoring, coupled with actionable insights from those monitoring activities, provide a roadmap for suppliers to make corrections and better themselves.

2. Evaluating On-Time Delivery Performance

Delivery compliance rates allow sourcing and supplier management teams to track whether or not their suppliers are meeting shipping deadlines. Monitoring this metric over time can help demonstrate which suppliers are reliable and consistent.

Our teams make hard commitments and track late shipments like a hawk. This helps them see each issue and spot trends that indicate larger issues or point to success.

3. Analyzing Cost Competitiveness and Value

When it comes to keeping costs in check, it’s about more than just checking price tags. Teams view what they are spending compared to other suppliers and market averages.

This forms a clearer picture of who provides the best value and better identifies opportunities to save dollars without sacrificing quality.

4. Assessing Supplier Risk Factors

Consider these metrics as a supplement to risk checks to help them spot weak spots, both in the supplier’s setup and in outside forces. Teams develop a sustainability risk framework and engage with their suppliers early on to avoid surprises.

This ensures that teams are prepared should circumstances shift.

5. Gauging Innovation and Responsiveness

Suppliers that generate novel solutions or resolve problems quickly are notable and memorable. Operational teams observe how suppliers respond to ad hoc requests, helping to address issues and add value through effective supplier management.

6. Tracking Sustainability and Ethical Practices

These days, scorecards focus on sustainability developments and equitable workforce initiatives. Procurement and operations teams ensure that suppliers comply with procurement rules.

They prioritize alignment around goals in waste, energy consumption, and equitable labor practices.

7. Integrating Quantitative and Qualitative Data

To arrive at the complete story, teams combine quantitative data with qualitative user and buyer feedback, utilizing a vendor scorecard to identify performance gaps that raw numbers may not capture.

Develop Your Supplier Scorecard

A well-developed supplier scorecard helps your teams align on a visible, consistent method for measuring and monitoring supplier performance. It identifies the most important criteria and gives them a score. This method allows all parties to see at a glance how a supplier is performing.

Most companies discover that having a good scorecard leads to easier conversations with suppliers and more straightforward decisions. Teams get a full picture and can spot where to push for more or where to thank a good job. Sharing and communication are the lifeblood of the scorecard.

Input from buyers, engineers, and finance professionals is key, as each of them knows what is most important in their respective realms. Engaging these voices from the beginning attends to all the critical elements.

Identify Critical Performance Areas

To do this, teams begin by identifying what areas of supplier performance are most important to focus on. On-time delivery, price, and quality will most explain the top list’s orders to the majority of shops. For others, it could be lead time on critical components or green sourcing.

These areas should be aligned with the firm’s major objectives, such as reducing costs or achieving net-zero emissions. As time goes on, it’s important for teams to reassess whether these areas are currently aligned. It’s difficult to make this leap and transitioning to new technology usually requires more speed and focus, not less.

Establish Clear Grading Criteria

For each of these areas, teams articulate criteria that establish what should be considered good, great, or poor. They tend to rate on a very basic 1–5 or 1–10 scale, with predetermined criteria for scoring under each. This keeps scoring impartial and allows procurement teams to identify broader trends.

Providing these rules to suppliers helps ensure everyone is aligned from the start. The clearer you are about what the score represents, the more likely your suppliers will be able to consistently hit their targets.

Choose Effective Scorecard Methodologies

Firms select scorecard tools that align with the way they procure and track items. A few rely on a balanced scorecard, which monitors cost, speed, risk, innovation, etc. Instead, many others employ ProQsmart, a powerful AI-driven tool that tracks supplier results and identifies potential problems in real time.

As time goes on, teams will want to continue adapting these tools to address emerging needs or new technologies.

Tailor Scorecards for Industry Needs

Scorecards are most effective when they are purposefully designed for the task. Car parts manufacturers might monitor defects as a percentage of total production, and home builders are concerned with days to first drop on site.

Teams can add or drop scores as the field evolves, such as scoring for green procurement guidelines or emerging supply chain hazards. Tools such as ProQsmart assist teams in quickly adding or modifying scores to proactive scorecard development.

Implement Supplier Performance Management

A cohesive supplier performance management (SPM) plan ensures that quality, cost, and timelines of custom manufacturing are controlled. When teams roll out a process to monitor supplier performance, they gain real-time insight into how each partner meets the set standards. An organized plan details the process and responsibilities for all parties, helping to ensure no detail falls through the cracks.

For instance, teams can leverage ProQsmart to automate workflows and continuously track and manage supplier performance with ease through built-in AI tools. This is what continues to make the demands process speedy, transparent and easy to navigate.

Set Clear Expectations Upfront

Getting SPM right begins with honest conversations. From day one, teams define what success looks like. Most importantly, they set strict standards for on-time delivery, targeted at 90% or above.

They impose aggressive product quality standards, usually at 95%. We write these targets into contracts with our vendors, so everyone is clear about the targets they are aiming for. Using ProQsmart, teams can easily upload these rules and quickly make them available to all partners simultaneously.

This encourages accountability, builds mutual trust, and ensures both parties are aligned.

Monitor and Evaluate Performance Consistently

Supplier performance should be reviewed on a consistent basis—whether monthly, quarterly, or annually—to identify trends and address issues in a timely manner. Technology platforms such as Ivalua and ProQsmart make this work easy.

They enable users to keep all performance records, contracts and performance scores in one centralized location. They can get the most recent numbers at their fingertips, compare them to KPIs, and identify slow or off-target results early.

Provide Constructive Feedback Regularly

Good SPM should allow for frank, honest conversations to take place very quickly about what is or isn’t working. Teams collectively celebrate successes but identify areas to improve with data—not finger-pointing.

With ProQsmart’s tools, feedback is instant in both directions, and manufacturers and suppliers can easily see a history of adjustments made.

Foster Continuous Improvement Together

Operations teams are often physically located next to key suppliers to troubleshoot and address deficiencies. They collaborate across departments to find creative solutions to reach ambitious targets, pilot new strategies, and party hard at every success.

This boots on the ground approach transforms minor improvements into significant advances.

Leverage Technology in Performance Tracking

Digital Custom manufacturing teams now rely on digital tools to ensure supplier performance remains top of mind. Powerful platforms enable them to backdrop, measure, and manage high volumes of supplier data quickly, with prepopulated dashboards and always-on monitoring. This move makes scorecard reviews much more efficient and thorough.

It brings everyone together to view the same data, uniting engineering, sourcing, and leadership teams across the chasms of data.

Automate Supplier Performance Measurement

Or, more efficiently, automated solutions such as ProQsmart reduce the burden of manual entry by automatically gathering and verifying data upon entry. The system signals compliance misses or late shipments, ensuring teams are notified as soon as possible.

This automation reduces errors. Entry errors are reduced by as much as 90%, and scorecards never have outdated information. Beyond scorecard creation, ProQsmart really simplifies bringing all your important metrics to one place, monitoring them regularly, and maintaining seamless workflows.

Tradogram provides even greater value through its all-in-one dashboards. These dashboards effectively combine performance scorecards with interactive collaboration platforms that keep everyone informed and on the same page.

Utilize AI for Predictive Insights

AI-driven analytics push these scorecards many steps further by detecting early signs of trends. ProQsmart uses artificial intelligence to sift through supplier data and identify red flags or opportunities for improvement.

This allows teams to understand what’s on the horizon, mitigate risks before they increase, and drive decision-making with actual data. These systems’ predictive insights result in better contract terms, smarter sourcing, and less supply chain disruption.

Integrate Scorecards with E-Sourcing

Connecting supplier scorecards to e-sourcing tools, as seen in ProQsmart, integrates sourcing, contract management, and performance tracking all in one place. That translates to supplier data flowing seamlessly and eliminating redundant entry.

Teams can easily turn to one source for the most up-to-date supplier insights. It streamlines RFP ranking, onboarding supplier engagement, and smarten relationships via real-time collaboration.

Ensure Data Integrity and Access

It’s important to always prioritize clean data. Technology platforms such as ProQsmart combine every contract, compliance form, and performance metric into a centralized location.

Conducting frequent scans for data quality keeps a finger on the pulse of reporting accuracy. Access controls ensure only the appropriate people get the information they need.

This arrangement prevents teams from overlooking errors until the last minute and ensures more consistent and objective supplier reviews.

Conclusion

Supplier performance scorecards add real data to each transaction and illustrate objectively where a relationship is at. Teams identify trends, address the weak link in the chain and witness victories materialize literally on the scorecard’s dashboard. Gone are the days of blind speculation when shipments are late or quality starts to fall. Every step now narrates a perfect tale. Shops utilize these tools to reduce waste, lower expense, and increase confidence with suppliers. A sheet of tracked scores can help a shop lock in better terms or drop a vendor that just can’t keep up. With data dashboards that provide real-time tracking, teams can identify what’s performing well and what’s underperforming at a glance and pivot quickly.

To make sure the growth continues, high performing stores are always keeping score and honing their craft. Looking to learn more about the supplier performance metrics scorecard? See how it works for yourself with a free demo. Explore ProQsmart and schedule your demo today!