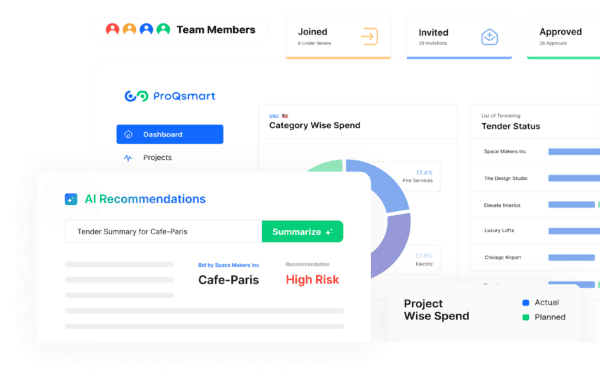

Elevate supplier collaboration, visibility, and efficiency with intelligent relationship management.

Foster stronger relationships with suppliers through a dedicated portal & corrective action plans

Automate and simplify the onboarding process, reducing cycle times by up to 50%

Automate and simplify the onboarding process, reducing cycle times by up to 50%.

Access real-time insights to inform your workflow strategies

Automate and streamline the onboarding process for new suppliers.

Provide a dedicated portal for suppliers to access information and collaborate.

Develop and track corrective action plans to address performance issues.

Automate and streamline the onboarding process for new suppliers.

Provide a dedicated portal for suppliers to access information and collaborate.

Develop and track corrective action plans to address performance issues.

Average cost savings on sourced goods and services

Increase in supplier participation in bidding events

Companies using Supplier Relationship Managment have reported

Reduction in time spent on sourcing activities

Digital audit trail, enhancing compliance and reducing risk

We’re constantly enhancing our platform to keep you ahead of the curve

With over a decade of experience in procurement technology, we understand your unique challenges.

Whether you’re a growing business or a global enterprise, our Supplier Relationship Managment grows with you.

Our team of experts is always ready to ensure your success.

Don’t let manual supplier management hold your business back. With ProQsmart’s Supplier Relationship Management solution, you’ll have the tools you need to stay competitive in today’s dynamic market.

Efficient Sourcing for New Constructions, Refurbishments, and Equipment

Optimize Procurement for Operational Efficiency

Streamline Sourcing for Property Upgrades and Chain-Wide Assets

Efficient Sourcing for New Constructions, Refurbishments, and Equipment

Optimize Procurement for Operational Efficiency

Streamline Sourcing for Property Upgrades and Chain-Wide Assets

In the project-based procurement, whether you are building a new franchise location, sourcing MRO for a factory, or managing a

AI quote comparison is the automated process of standardizing inconsistent data from multiple vendor bids into a single, uniform format.

AI for supplier response comparison is the application of artificial intelligence to automatically extract, structure, and analyze bid data from

To understand why you need a specialized tool, you first need to understand what generic AI actually does. Tools

Scope gap detection is the automated process of identifying missing line items, incomplete descriptions, or unquoted services within a vendor’s

Automatic bid comparison is the process of using artificial intelligence to extract, normalize, and analyze line-item data from disparate vendor

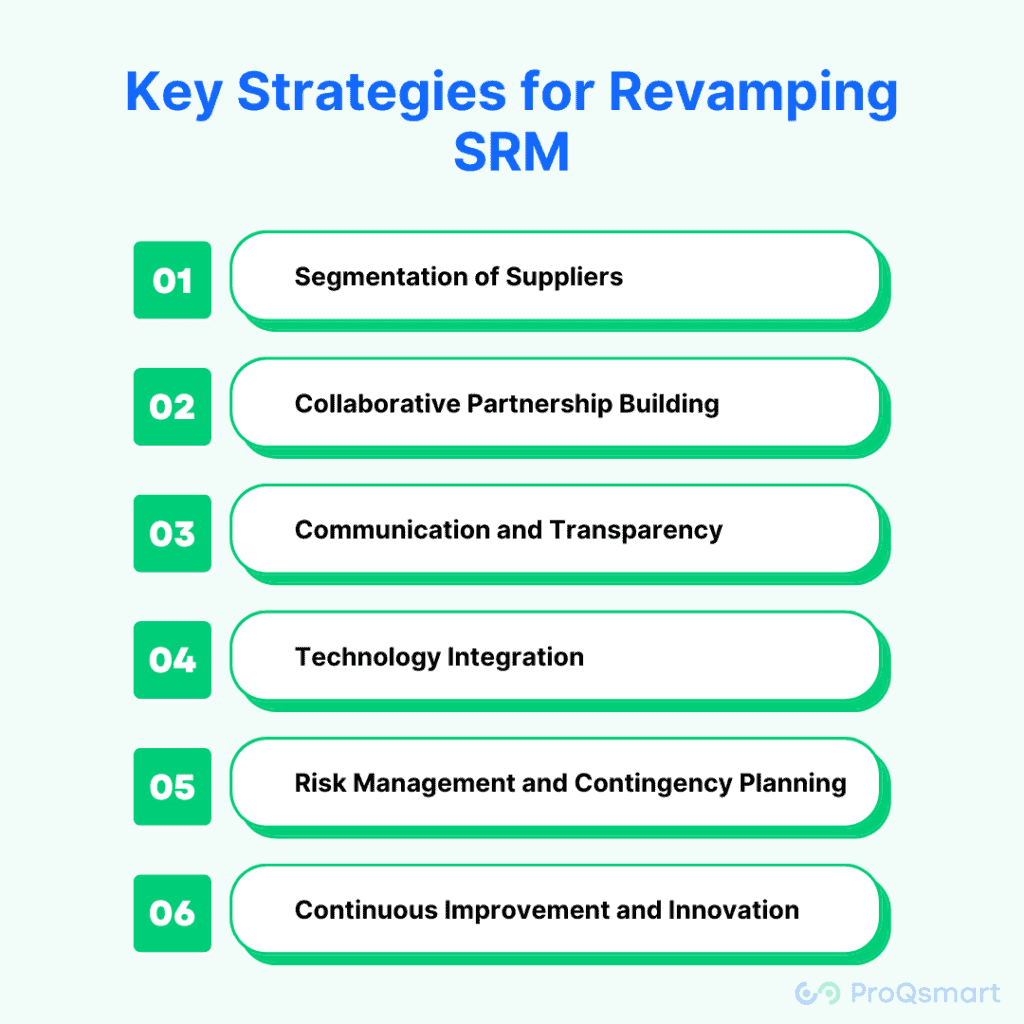

In the complex realm of procurement, Supplier Relationship Management (SRM) stands as a critical pillar, influencing not only the immediate supply chain efficiency but also the broader strategic success of businesses. Revamping SRM practices can lead to improved partnerships, enhanced performance, and significant competitive advantages. This blog delves into the essential strategies for transforming SRM processes to achieve optimal business outcomes.

SRM encompasses a wide range of interactions with suppliers, from transactional relationships focused on short-term purchases to strategic partnerships that drive long-term value. A crucial step in revamping SRM is assessing these relationships to identify areas for improvement and opportunities for deeper collaboration.

Categorize suppliers based on their importance to the business, focusing on strategic suppliers who provide critical products or services. This segmentation facilitates tailored relationship management approaches that align with business priorities.

Establish clear performance metrics that are aligned with business objectives. Regularly evaluate suppliers against these metrics to ensure they meet expected standards and contribute to business goals.

Move beyond transactional relationships and develop collaborative partnerships with key suppliers. This involves shared planning, joint development initiatives, and mutual investments in success.

Foster open and transparent communication channels with suppliers. Regular interactions, feedback, and information sharing are essential to build trust and address issues proactively.

Leverage technology to streamline SRM processes. Advanced SRM software can provide real-time data on supplier performance, facilitate communication, and help manage contracts and compliance more effectively.

Implement comprehensive risk assessment mechanisms and develop contingency plans for critical supply chain segments. This proactive approach helps mitigate potential disruptions and ensures supply chain resilience.

Encourage continuous improvement and innovation within the supplier base. Engage with suppliers to explore new ideas, improve products or services, and optimize processes for mutual benefit.

Revamping SRM practices can significantly impact a business’s bottom line and strategic positioning. Enhanced supplier relationships lead to improved supply chain reliability, cost efficiencies, and access to innovation. Moreover, strong SRM practices can improve market responsiveness, adaptability, and overall competitive advantage.

In the dynamic landscape of modern business, effective Supplier Relationship Management is more than a procurement necessity; it’s a strategic imperative. By revamping SRM practices, companies can transform their supplier relationships from mere transactions to powerful, collaborative partnerships that drive business success. Embracing the strategies outlined above can lead to a more resilient, innovative, and competitive business model, leveraging the full potential of supplier networks to achieve lasting success.

Supplier Relationship Management (SRM) is the systematic approach to evaluating suppliers’ contributions to a business and developing strategies to foster positive supplier relationships, ultimately driving efficiency and value in the procurement process.

Revamping SRM is important because it helps businesses adapt to changing market conditions, improve supplier performance, reduce costs, and leverage supplier innovation, leading to enhanced competitiveness and success.

Businesses can segment their suppliers based on criteria such as spend volume, strategic importance, risk factors, and performance levels. This helps in applying different management strategies that are appropriate for each supplier segment.

Key performance metrics in SRM can include quality of goods or services, delivery timeliness, cost management, innovation contribution, and adherence to contractual agreements.

Collaboration with suppliers enhances SRM by building trust, improving communication, aligning objectives, and working jointly on innovation and continuous improvement, which can lead to better products, services, and business outcomes.

Technology plays a critical role in SRM by providing tools for better data management, performance tracking, communication, and process automation, which helps in making informed decisions and fostering strong supplier relationships.

Risk management can be integrated into SRM by conducting regular risk assessments, monitoring supplier performance and market conditions, and developing contingency plans to address potential disruptions in the supply chain.

Yes, small businesses can significantly benefit from revamping their SRM practices as it can lead to improved supplier performance, reduced costs, and access to innovations and market opportunities, contributing to their growth and sustainability.

Challenges in revamping SRM include resistance to change within the organization, difficulties in supplier engagement, the complexity of integrating new technologies, and the need for ongoing management and training.

Continuous improvement is a core aspect of SRM, focusing on regularly assessing and enhancing supplier performance, fostering innovation, and strengthening relationships to drive ongoing value and adapt to evolving business needs.