Supplier Relationship Management (SRM) is a powerful approach that enables organizations to strengthen their procurement strategies and achieve greater business resilience. By focusing on building productive, long-term partnerships with suppliers, companies can ensure a more reliable flow of materials, control costs, and consistently improve quality standards.

Effective SRM leads to open communication and collaboration, reducing the likelihood of disruptions and delays. It also facilitates the adoption of new technologies and sustainable practices, making it easier for businesses to adapt to changing market conditions. In industries where price fluctuations and rapid shifts are common, strong supplier relationships offer a clear competitive edge.

This article explores practical steps and essential tools to help you develop and maintain robust supplier relationships, along with actionable advice for making these partnerships last.

What Is Supplier Relationship Management?

Supplier relationship management, or SRM, is an important strategic approach for managing complex vendor relationships. It’s about more than just traditional supplier management; rather, it focuses on establishing productive, long-term relationships with suppliers. When executed correctly, modern supplier relationship management transforms suppliers from just another vendor into a significant asset to the business.

SRM gives your organization the ability to be agile and respond swiftly. Effective supplier performance management means you’ll be able to obtain what you need tomorrow. It’s about anticipating and proactively preparing for future demands, risks, and challenges while collaborating with strategic suppliers to innovate and deliver solutions.

Creating a successful SRM strategy is not a one-time activity. Through segmentation, this cycle ranks suppliers based on their risk, spend, location, or sustainability. It further encompasses strategic planning, tactical execution, performance measurement, and continuous enhancement of supplier management practices.

With the right supplier relationship management platform and a clear framework, teams can track supplier performance, fix problems quickly, and find new ways to work better together.

Core Components Of Effective SRM

- Two-way communication

- Trust and mutual respect

- Shared goals and values

- Clear performance metrics

- Supplier segmentation

- Strategic planning

- Tech-driven tracking tools

Coordinating supplier objectives in line with organizational goals creates positive energy, enhancing supplier collaboration. Supplier portals or dashboards serve as a supplier relationship management platform, providing convenient tech solutions for sharing updates and tracking progress collaboratively.

SRM’s Role In Supply Chain Resilience

Having strong ties with suppliers can improve the ability to identify risks earlier, address vulnerabilities, and recover from disruptions. For example, during recent supply chain shocks, firms with solid SRM weathered shortages better by working closely with vendors to shift production or source alternatives.

Continued collaboration allows teams to adapt to market fluctuations and maintain momentum.

How SRM Drives Competitive Edge

A high-quality SRM program can drive competitive advantage. A sincere commitment to deep collaboration with suppliers promotes quicker innovation, improved quality and increased delivery reliability. Armed with these supplier insights, companies are better positioned to make more strategic decisions and identify emerging patterns.

Ultimately, this philosophy raises bottom line and organizational prosperity.

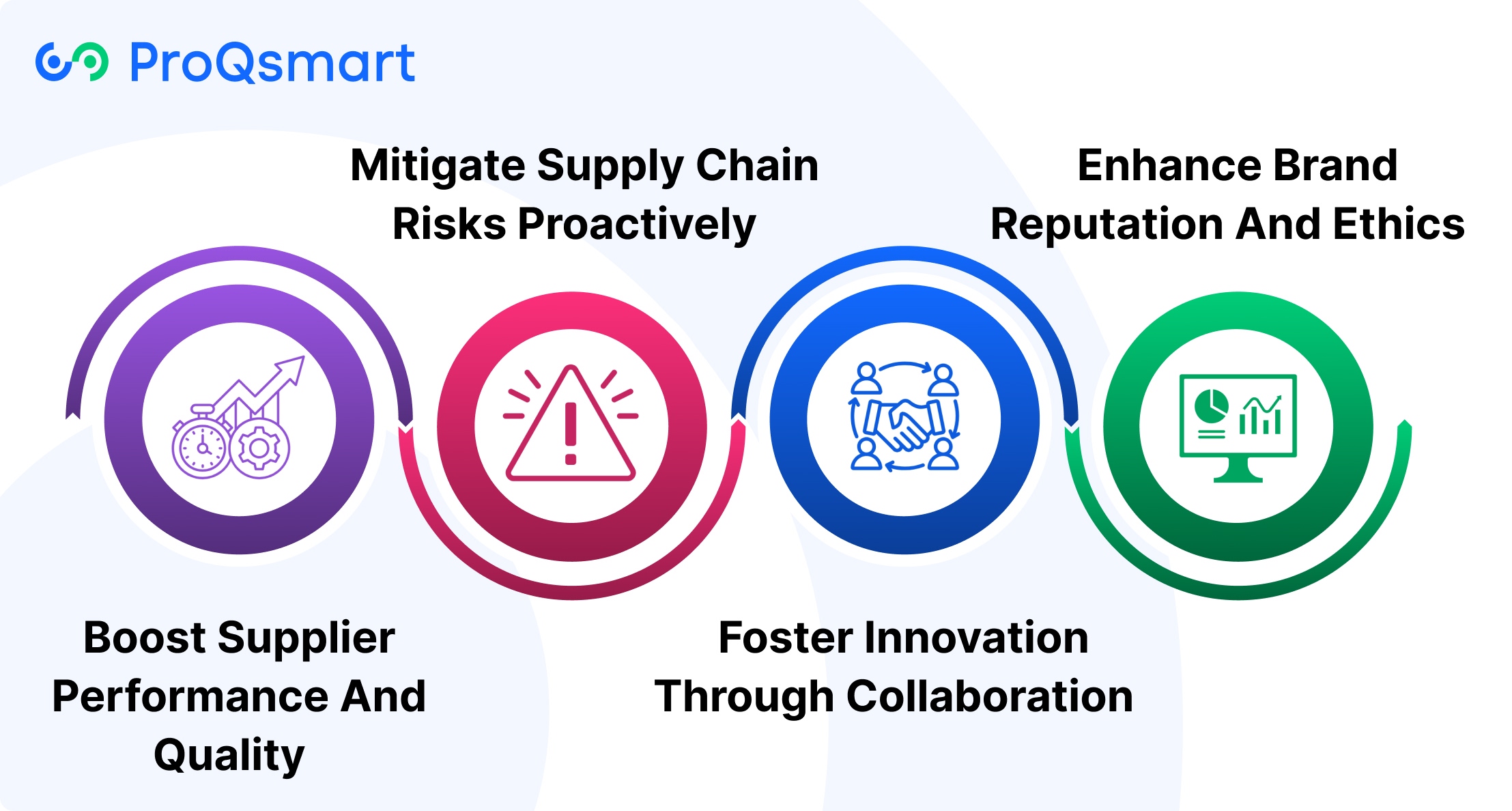

Key Benefits Of Mastering SRM

Here are some key benefits of mastering SRM. A well-built supplier relationship management (SRM) strategy brings measurable value to custom manufacturing. Companies that embrace SRM will realize benefits in reduced costs, improved quality, and enhanced risk management.

A structured approach lets teams use the full skills and tools suppliers offer, making day-to-day work smoother and less prone to sudden issues. These benefits are especially important for proactive manufacturing executives who understand the need to remain competitive in order to achieve long-term success.

Key advantages of mastering SRM include:

-

Cost savings from optimized sourcing and process improvements

-

Higher quality parts and reduced defects

-

Lower risk of supply chain disruptions

-

Stronger supplier loyalty and engagement

-

Improved operational efficiency and speed

-

Faster innovation cycles

-

Better insight for informed decision-making

Boost Supplier Performance And Quality

Defining a set of clear, shared performance metrics helps to align all parties toward the goal. Frequent evaluations and an always-open line of communication with your suppliers lead to higher-quality suppliers that continue to meet your needs over time.

Frequent, frank discussions with suppliers help create an environment where it’s easier to address activities that could lead to larger issues. Collaboratively developing solutions fosters trust and ensures quality is maintained.

Mitigate Supply Chain Risks Proactively

Common risks like delays, shortages, or quality drops can be managed by building strong SRM frameworks. Assessing risks early and often helps teams prepare.

Joint planning with suppliers for backup options means fewer surprises. Honest, two-way communication is key for quick fixes when things go wrong.

Foster Innovation Through Collaboration

Suppliers are typically on the cutting edge of new ideas and new technology. By co-developing products, manufacturers and states are both able to work more quickly.

Research indicates that external partnerships can help bring solutions to market 40% faster. Examples might be collaborative-joint prototyping projects or collaborative-shared research on advanced materials.

Enhance Brand Reputation And Ethics

Better supplier relationship management fosters these initiatives by ensuring ethical sourcing, promoting supplier diversity, and advocating for fair treatment of suppliers. Transparent systems and strong values are reflected in each supplier decision, enhancing supplier engagement and building public trust while meeting or exceeding regulatory demands.

Smart SRM Strategies For Success

Supplier relationship management (SRM) is a strategic practice that fundamentally determines how companies engage with their most important partners. It’s what keeps the supply chain moving and then some. It creates true win-win for both parties and fosters mutual growth and prosperity.

Robust SRM programs combine thoughtful strategy, the right stakeholder mix, ongoing evaluation, and an emphasis on securing long-term benefits. For one, smart SRM begins with organizing a cross-functional team. At a minimum, this team requires a steering committee, a strategy group, action-oriented SRM ambassadors, and a technical support team.

These small groups not only assist in connecting business objectives to supplier requirements, they assist in maintaining momentum in the process. With the help of tools such as ProQsmart, procurement teams can easily oversee e-tenders, monitor budget allocations, and realize the performance of suppliers in real-time.

This allows them to make go/no-go decisions quicker and ensures all stakeholders are aligned and informed.

Best Practices for SRM Implementation:

-

Prioritize and segment suppliers to fit their importance and risk level to your business.

-

Use supplier awards or exclusive deals to boost performance.

-

Hold regular business reviews and feedback sessions.

-

Tie SRM to sustainability certifications and audit tools.

-

Build clear processes for supplier-led innovation.

-

Set up metrics that reward proactive problem-solving.

It is important to get these steps right for each industry. Climate tech companies can focus on ESG adherence and third-party verification and certification. In consumer tech companies, speed and flexibility are the focus.

It doesn’t matter what industry you are in, continuous improvement is the name of the game. As markets change, SRM teams need to constantly reassess their supplier portfolios and approach. They must use metrics and do consistent check-ins to spot problems early and push for better outcomes.

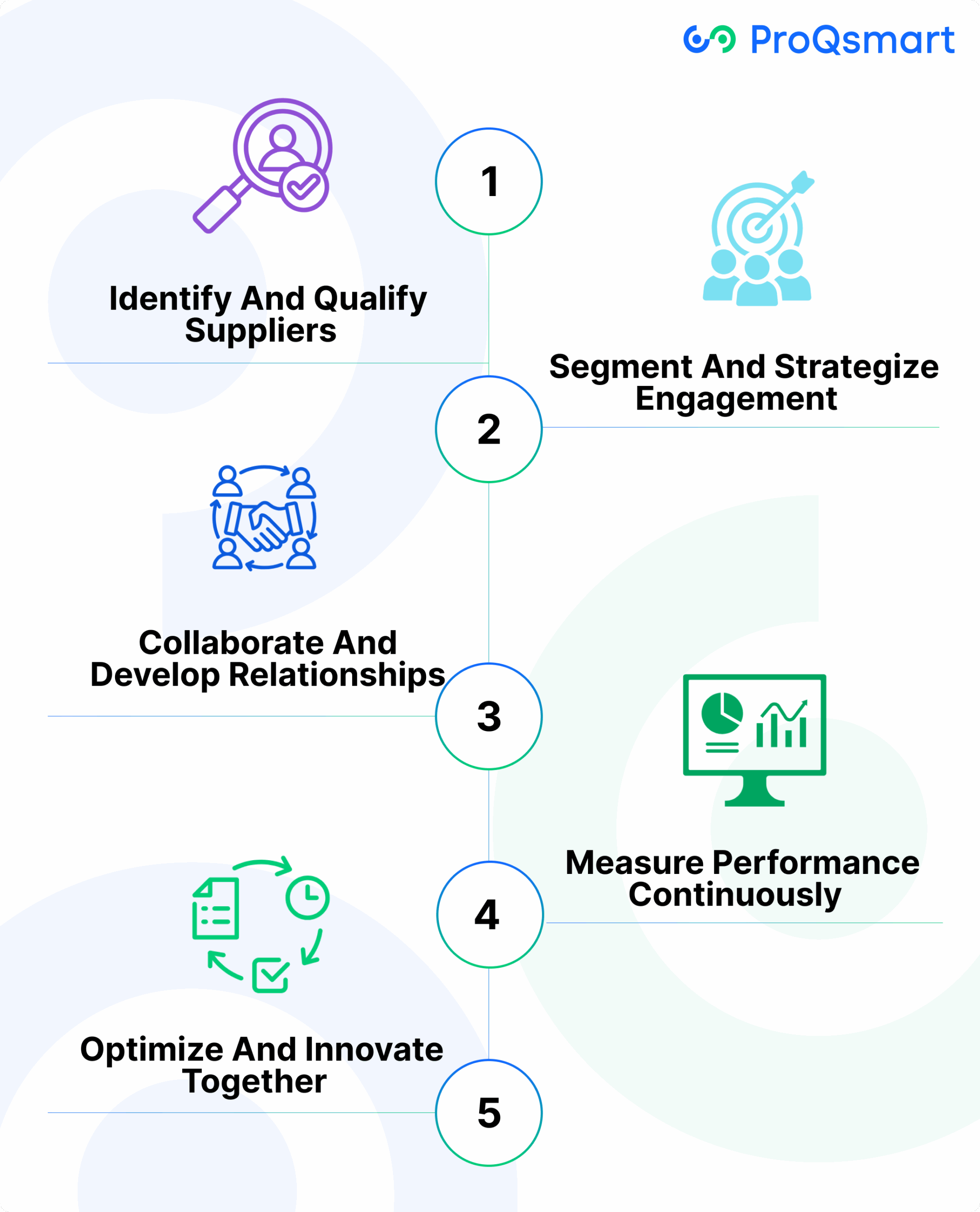

Implementing The SRM Process

A well-defined supplier relationship management (SRM) process inspires companies to establish rapport and explore creative new ways of partnering. This new approach focuses on realizing long-term value from their partners. In the case of manufacturing or custom prototyping, a collaboratively run SRM process is much more than a basic checklist.

It establishes a virtuous process that connects people, information, and technology to improve decision-making and achieve meaningful outcomes. The SRM process works best when it’s built around five clear steps: segmentation, strategy development, relationship building, execution, and improvement. Each phase relies on input from cross-functional teams: SRM steering committees set high-level goals, strategy groups define tactics, SRM leaders drive daily actions, and core teams handle the details.

Key Phases in the SRM Process:

-

Identify and qualify suppliers

-

Segment and strategize engagement

-

Collaborate and develop relationships

-

Measure performance continuously

-

Optimize and innovate together

Phase 1: Identify And Qualify Suppliers

Identifying qualified suppliers goes beyond checking a box. Teams take a deep dive into supplier capabilities, track record and alignment to business objectives. Due diligence—conducting audits, examining past performance and compliance history—eliminates the weakest links.

Digital tools such as ProQsmart are revolutionising how teams collect supplier information and conduct e-tenders. With AI, they further automate document reviews, speeding up qualification and improving accuracy.

Phase 2: Segment And Strategize Engagement

To better determine how they will engage with suppliers, grouping them by risk, spend, or potential for innovation can help engage the right strategy. A combination of qualitative and quantitative data analysis informs the creation of these groups.

As an illustration, strategic suppliers will require more penetrating relationships and collaborative initiatives, whereas the remaining suppliers lend themselves to more rudimentary, transactional interactions. These constituencies should be monitored regularly, particularly as organizational objectives or market conditions change.

Phase 3: Collaborate And Develop Relationships

Developing deep connections involves collaboration, not just stacking requests. Open dialogue, co-creative problem-solving, and mutual trust-building—such as through joint collaborative workshops or joint innovation programs—benefit actors from both sectors.

Consistent feedback and structured quarterly calls help preserve these relationships and ensure alignment around objectives.

Phase 4: Measure Performance Continuously

Effective SRM follows the wider value—not just costs, but new concepts and risk reductions/savings. Teams rely on scorecards, KPIs, and benchmarking to ensure that suppliers are performing at the right level.

ProQsmart’s real-time dashboards and performance management simplify this, with integrated scorecards and automated feedback loops.

Phase 5: Optimize And Innovate Together

Collaborative projects and development of mutually beneficial standard operating procedures improve supply chain performance. Teams conduct idea challenges, provide critique, and bring in vendors to propose new technologies or approaches.

An atmosphere of transparent evolution and continuous evaluation fosters an agile environment. This lets everyone on both sides adjust to changing demands and find new efficiencies.

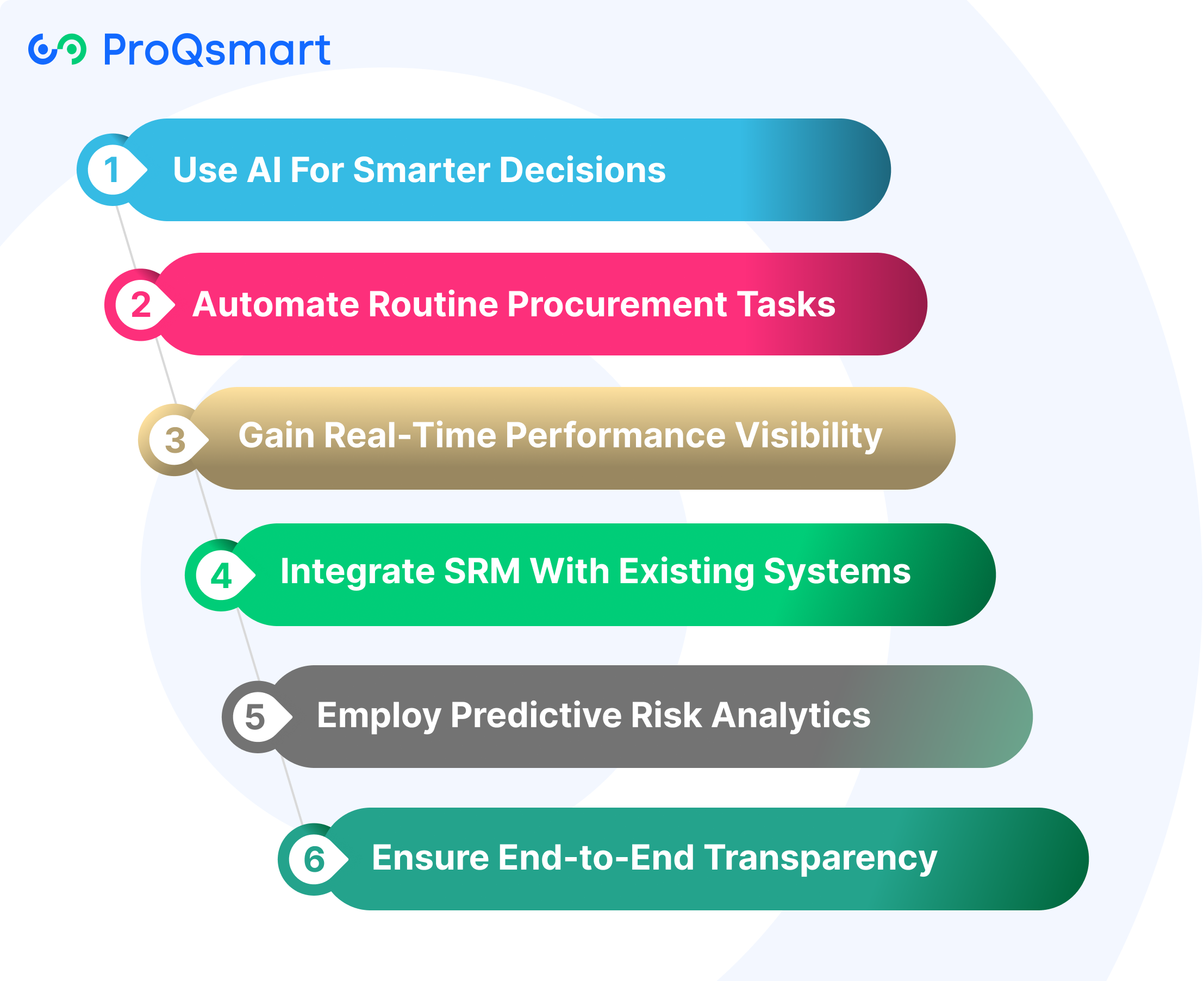

Leverage Technology For Better SRM

Technology is impacting the way the industry can establish and maintain close relationships with suppliers. This move to digital tools is more than a desire for efficiency. It’s about transparency, better decisions, and more effective collaboration.

By using the right systems, teams can clear paths for time-consuming admin tasks. This creates an opportunity for them to develop additional vendor relationships and attract new partners. Having one integrated platform to handle all requests, whether it’s through a single dashboard or orchestration layer, reduces the noise and provides greater oversight.

Supplier portals, e-procurement systems, and integrated CRM and SCM platforms tech up teams to easily monitor agreements and oversee paperwork. They enable more seamless, real-time communication with vendors.

A bullet list of key tech tools for SRM:

-

Supplier relationship management (SRM) software

-

Electronic procurement systems

-

AI-powered analytics platforms

-

Supplier portals for collaboration

-

Integrated CRM and SCM systems

-

Performance tracking dashboards

-

Centralized document management

-

Automated workflow tools

Getting the most from these tools will require connecting SRM tech to what’s already out there. This effectively connects procurement, finance, and operations together for a seamless and quick data flow. Continuous training and ongoing engagement is critical so that teams are using the technology effectively, identifying trends quickly, and able to take action quickly when conditions change.

Use AI For Smarter Decisions

AI tools process massive data sets quickly and efficiently, finding trends and patterns that a team of researchers could overlook. In SRM, AI monitors supplier performance and identifies potential risks. It would allow you to identify problems such as late deliveries or cost increases early enough to avoid damaging a project.

American companies are leveraging AI for predictive analytics, monitoring supplier performance metrics, and identifying future actions. AI-powered, data-driven insights allow your team to select the best fit partners and proactively plan for the future. Increasingly, investing in AI is table stakes for companies that hope to be on the cutting edge of procurement.

Automate Routine Procurement Tasks

Manually processing or tracking orders, checking invoice status, or uploading documents eats up valuable time on procurement teams. Automated tools improve efficiency by doing these jobs and reducing mistakes. Choosing the right automation for each requirement helps ensure a smooth operation.

It’s a best practice to audit these tools from time to time to ensure that they are aligned with team objectives.

Gain Real-Time Performance Visibility

Real-time tracking provides teams with a picture of supplier behavior. Technology—dashboards, for example—provide insight into whether a vendor is on schedule or failing to deliver. Real-time visibility into performance data translates into quicker repairs.

Distributing these results builds a level of trust with suppliers and helps find open lines of communication.

Integrate SRM With Existing Systems

Integrating SRM with existing systems helps ensure info can keep flowing easily. This enables teams to gain a complete view – from spend to risk – all in one place. This is where ProQsmart brings AI into the equation.

It provides teams with tools to track bids, control budgets, and track supplier performance. ProQsmart’s dashboard feeds in all the important data. It streamlines contract reviews, change management, vendor management processes—all while ensuring compliance.

Employ Predictive Risk Analytics

For instance, predictive analytics can monitor signs of distress or disruptions in supply chains. Using historical data, these tools predict where problems may occur. Scenario planning can be a valuable exercise to ensure your team is ready for unexpected surprises.

Investing in these tools allows teams to take action before a minor bump in the road becomes a major crisis.

Ensure End-to-End Transparency

Transparency of information is key. Transparency, or clear, open information, is the foundation of trust. Technology that provides transparency throughout the entire process, from order to delivery, ensures everyone involved is informed.

Shared dashboards and open channels of communication ensure that nobody is out of the loop. This level of transparency is quickly becoming the norm in SRM.

Conclusion

Close supplier relationships are essential for keeping your operations agile and competitive. Effective supplier relationship management not only reduces duplication and waste but also helps control costs and ensures you’re prepared for future opportunities. By leveraging smart technology, you can spot and resolve issues early, gaining direct, transparent data for every purchase-eliminating guesswork and delays.

When your SRM processes are strong, your team can quickly adapt to disruptions, such as late deliveries, by seamlessly switching to alternative suppliers. This level of responsiveness keeps production on track and customers satisfied. These proactive strategies don’t just save money-they lay the groundwork for sustainable growth and long-term success.

To stay ahead of the competition, focus on building trust, regularly auditing your procurement data, and choosing solutions that align with your current needs and future goals. Ready to elevate your supplier relationships and drive smarter procurement? Explore how ProQsmart can support your journey-schedule a demo with us today!