Relying solely on reactive risk management exposes businesses to preventable disruptions in their supplier management process. Proactive strategies, combined with tools like ProQsmart’s AI-driven risk assessments, enable effective management and early identification of potential issues.

Table of Contents

How AI Transforms Supplier Database Management?

AI-powered supplier relationship management has transformed the old-school, transactional supplier procurement practice into an efficient and strategic endeavor. By automating time-consuming processes and improving overall decision-making, AI enhances the supplier management process flow. It delivers predictive insights, allowing organizations to proactively manage their supplier landscape and foster operational excellence.

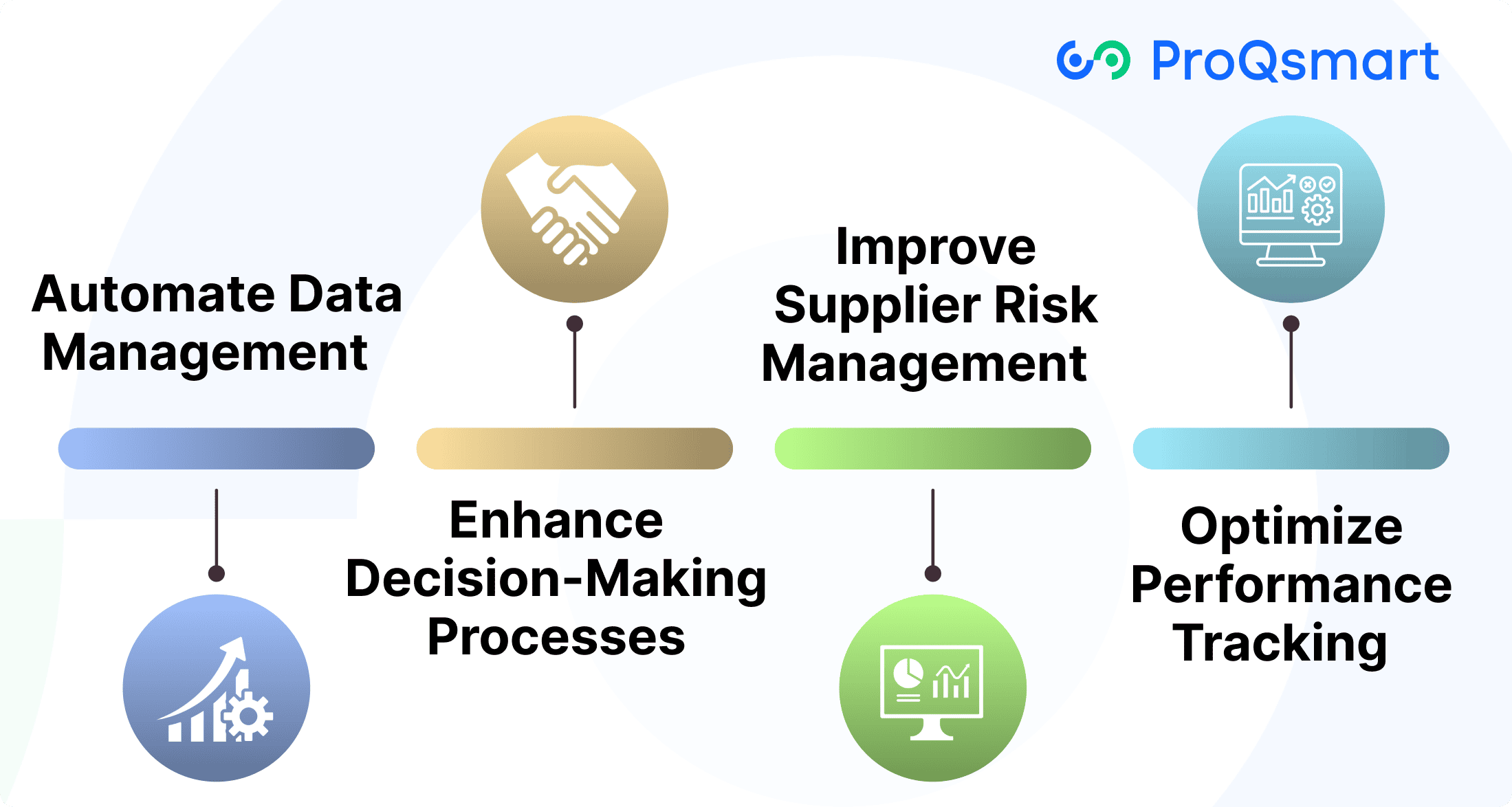

1. Automate Data Management

AI-powered systems help prevent manual errors by automating supplier data entry, updates and validation. These systems help maintain uniformity of data, allowing procurement teams to have up-to-date and trustworthy records of suppliers.

For instance, AI-optimized Supplier Onboarding and Management systems use dynamic registration criteria and KPI-based scoring to automatically filter out risky suppliers, simplifying supplier review processes. This impacts both time savings and collaboration since it prevents administrative bottlenecks within human resources from hindering collaboration.

2. Enhance Decision-Making Processes

AI is able to provide actionable insights through the analysis of global supplier networks, enhancing supplier relationship management to pinpoint trends and improve supply chain performance.

3. Improve Supplier Risk Management

AI never stops evaluating supplier risks, providing real-time alerts and suggestions to prevent future problems before they start. By connecting with third-party data providers, AI enhances supplier relationship management and helps paint a complete picture of risk profile, allowing businesses to stay ahead through proactive supplier management strategies.

4. Optimize Performance Tracking

Not surprisingly, AI-driven tools are already monitoring supplier performance in real-time, utilizing KPIs to determine the extent of contributions. Platforms like ProQsmart enhance this by automating workflows, tracking compliance, and aligning procurement with budgets.

Benefits of AI-Driven Solutions for Supplier Management

AI-driven solutions are revolutionizing supplier management, providing organizations with unprecedented efficiency, accuracy, and strategic insights. These innovations help make more complicated procurement processes much easier. They drive stakeholder collaboration and accountability.

These solutions empower organizations to drive better outcomes by enabling more informed, data-driven decisions.

Increased Efficiency and Productivity

By automating routine tasks such as data entry, invoice handling and payment processing, AI not only saves time but ensures a higher level of accuracy and compliance. For example, automation lowers procurement processing costs by 30% and increases operational efficiency by as much as 45%.

By automating supplier onboarding and other repetitive administrative tasks through the incorporation of AI, procurement teams can prioritize more strategic activities such as supplier development. This kind of efficiency empowers businesses to fulfill customer demands faster than ever.

Reduced Costs and Errors

Through predictive analytics, AI helps lower supply chain forecasting errors by up to 50%, leading to huge operational cost savings. Through automated data management, users can have error-free supplier records, compliance tracking, and reporting.

In one instance, ProQsmart’s budget-driven procurement feature automatically aligns expenditures as they happen, avoiding overspending. By automating processes and improving data accuracy, companies can achieve savings of 10-15%.

Improved Supplier Relationships

In short, maintaining strong supplier relationships greatly benefits business success. AI-powered solutions allow for seamless communication and performance monitoring in real-time, which helps to promote transparency and trust.

Multi-stakeholder collaborative platforms like ProQsmart deepen and protect this collaboration through equal opportunity dispute resolution and ongoing supplier performance evaluations, keeping relationships healthy long-term.

Enhanced Risk Mitigation

Effective risk mitigation is crucial in supplier management to ensure supply chain resilience. By leveraging advanced technologies, businesses can proactively identify and manage potential risks associated with suppliers. ProQsmart offers tools that help assess supplier performance and potential hazards, providing actionable insights to reduce vulnerabilities in supplier networks.

This approach enables organizations to anticipate and address risks early, fostering a more secure and reliable supply chain. By integrating risk management strategies into supplier management processes, businesses can better protect themselves against disruptions and maintain operational continuity.

Better Procurement Outcomes

Informed, data-driven insights ultimately result in higher quality goods and services. AI’s predictive capabilities keep up with demand and guide with the most efficient sourcing.

ProQsmart turns procurement goals into measurable results, setting you on a path toward long-term success.

Implementing AI and Automation

Integrating AI and automation into the supplier management process enhances operational efficiency and accuracy while improving decision-making capabilities. Effective management requires a comprehensive supplier management policy to ensure a smooth transition and realize the full potential of supplier collaboration.

Automate Repetitive Tasks

Automation can streamline repetitive yet essential tasks. These include data entry and processing supplier invoices, performance tracking and monitoring compliance metrics, and conducting routine checks for regulatory adherence.

Automating these processes frees teams to focus on higher-value strategic priorities, like negotiating for suppliers and positioning the organization to innovate in sourcing practices.

Through a strategic resource reallocation to prioritize higher-value activities, procurement professionals are perfectly poised to deliver innovation and competitive advantage.

Leverage AI for Predictive Analytics

AI’s power in predictive analytics gives procurement teams the ability to make smarter decisions based on insights that can be acted on. Use historical data matched with real-time inputs to better predict upcoming supplier performance, analyze and mitigate supplier risk, and inform more effective sourcing strategies.

AI can help organizations, such as predicting a supplier’s capacity to respond to just-in-time deadlines or evaluating vulnerabilities in critical, high-risk categories. AI tools optimize inventory management, automating replenishment while analyzing stock levels and transportation options, ensuring resilience and efficiency across the supply chain.

Enhance Supplier Networks

Technology enhances supplier networks by fostering diversity and resilience. Collaborative AI solutions can evaluate supplier risks, streamline onboarding, and build transparent relationships based on trust.

For example, AI-driven risk assessments provide data critical to strengthening partnerships and mitigating disruptions.

Integrate AI with Existing Systems

Seamless integration of AI into existing procurement systems will facilitate continued, effective supplier relationship management and two-way data flow efficiencies. Successful supplier partnerships are key to unlocking AI’s full potential value and improving operational cost efficiency.

Measuring and Tracking Performance

Measuring and tracking supplier performance regularly is an essential first step to more mature supplier management. It should be the basis for recognizing what you do best, correcting what needs work, and making sure all activity is aligned with overarching business objectives.

This data innovation means that a structured approach to monitoring performance should undergird and drive quality and reliability. Second, it promotes better informed decision-making when developing procurement strategies. With defined expectations and specific metrics, one can build strong, long-lasting supplier relationships while meeting the markers of an efficient operation.

Key Performance Indicators (KPIs)

Proactive measures of success are essential for evaluating suppliers. Essential KPIs include low defect rates and high First-Pass Yield (FPY) which highlight quality systems that reduce rework and boost efficiency.

KPIs not only direct supplier evaluations, they drive suppliers to make positive improvements. Aligning them with high-level business objectives ensures your suppliers are working towards goals that contribute directly to your goals.

Tools such as ProQsmart make tracking performance low effort, presenting users with automated insights and easy ongoing performance monitoring.

Performance-Based Contracts

Performance-based contracts align suppliers to reward them for good performance and penalize them for the opposite. By tying compensation to specific outcomes, it pushes suppliers to ensure they meet—and indeed exceed—quality and timeliness.

As an example, incentivizing regular on-time delivery or defect-free deliveries increases accountability while helping guarantee that value is directly tied to performance.

Data Transparency and Reporting

Data transparency is the first step toward effective supplier management. Clear reporting enhances trust and accountability, while data sharing fosters collaboration.

Automated supplier solutions, such as ProQsmart, take the pain out of supplier data management by replacing Excel and other labyrinthian systems. Functionality such as three-way matching helps you maintain fully accurate performance metrics and keep your processes running smoothly.

Conclusion

Supplier management has a critical impact on maintaining operational continuity and helping to control costs. With AI and automation, this process becomes much quicker and more consistent. These tools proactively reduce errors and improve your data management efforts. This will leave you with increased time to develop more strategic relationships with key suppliers. With cloud-based tools like ProQsmart, you’ll simplify database management and have a reliable way to consistently evaluate supplier performance.

While implementing AI-driven solutions might seem like a fad to some, it’s actually crucial to staying ahead of the curve. It’s not—you don’t want to take that step in like a competitive market, you know, reducing wasteful spend and aligning what you do with measurable business objectives.

Ready to modernize your supplier management? Book a demo with ProQsmart today to discover how our innovative solutions can help you achieve better procurement efficiency and strategic supplier management.