In terms of procurement, the Request for Quotation (RFQ) is absolutely critical. An RFQ is a formal, structured request by a corporation to potential suppliers seeking price quotes for set quantities of defined goods or services. This document is not only a request for price, it establishes the groundwork for creating clear procurement expectations.

RFQs help to explicitly outline a project’s scope and requirements. This alignment is an important way to make sure both the buyer and supplier know what they’re getting into before money changes hands. Having this clarity allows you to avoid any potential misunderstandings and provides a smoother procurement process.

RFQs force competing suppliers to undercut one another. Vendors are incentivized to put their strongest proposals forward to earn the business. This increased competition then translates directly to better terms and lower costs for the buying organization.

Definition of Request for Quotation (RFQ)

An RFQ, or request for quotation, invites multiple vendors to submit their best price quotes, particularly for high-value purchases. It provides essential details, including the quantity of products or services needed, delivery timelines, and other information required by suppliers. This clarity enables vendors to offer competitive quotes tailored to the organization’s specific requirements.

Importance of RFQ in procurement

The RFQ process is essential for organizations to make informed purchasing decisions by obtaining multiple quotes and exploring different offerings.

It allows companies to choose options that best meet their priorities for cost, quality, and on-time delivery.

RFQs promote transparency in procurement by standardizing requirements and expectations among all respondents, fostering trust and accountability.

Competitive bidding through RFQs can lead to significant cost savings, which is crucial for managing constrained budgets and maximizing value for money.

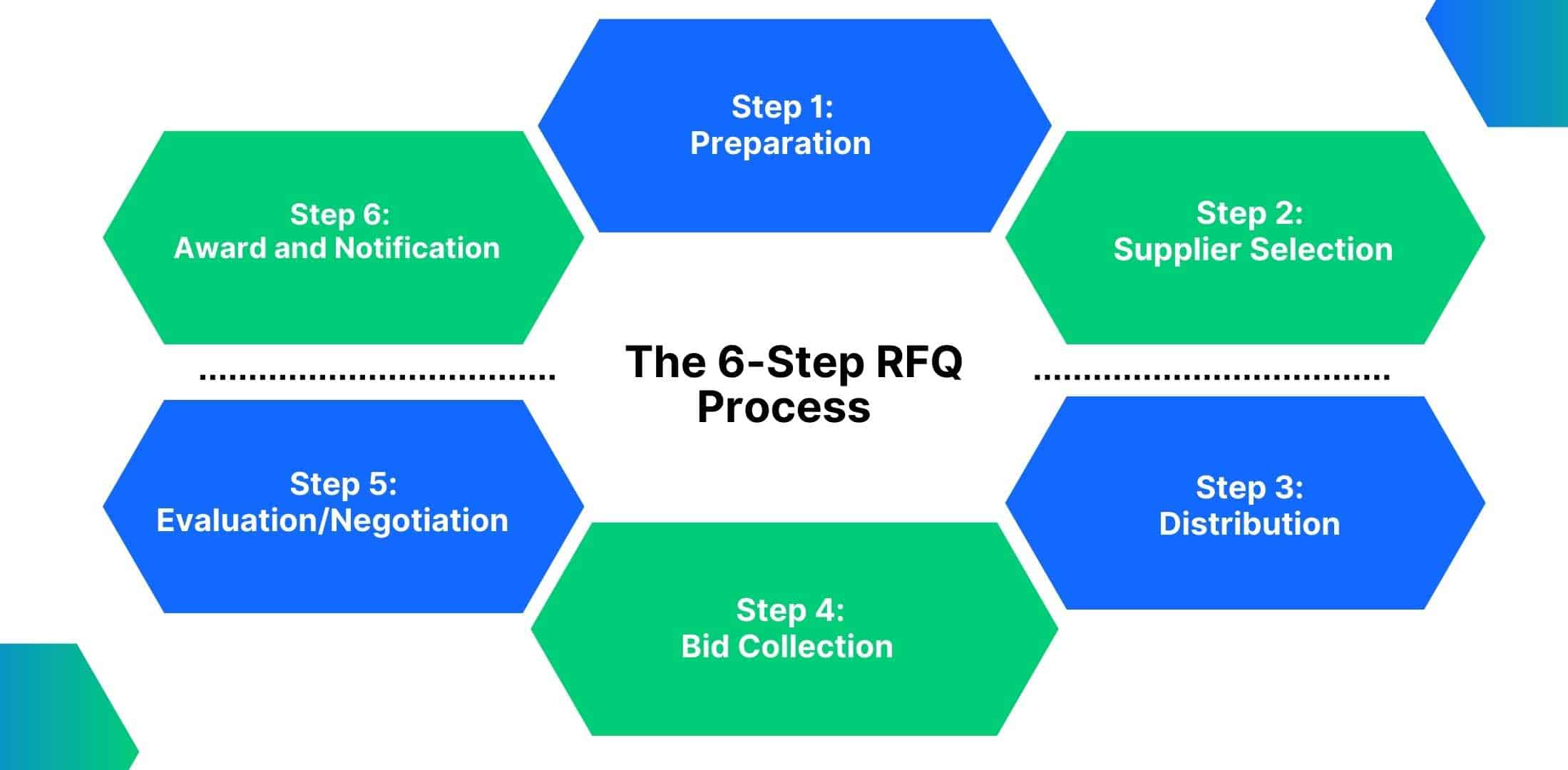

The 6-Step RFQ Process

The RFQ process offers a structured approach for procurement professionals to acquire goods and services effectively. This disciplined method is essential for achieving procurement goals and fostering valuable supplier relationships. A well-executed RFQ ensures that organizations obtain exactly what they need.

Step 1: Preparation

As with any procurement process, preparation is the key to a successful RFQ process. It starts with defining what you need, and knowing the project inside and out. Setting a budget and timeline from the beginning is essential.

This clarity gives the procurement team the mandate needed to tailor the RFQ and best achieve the organization’s priorities. Having an effective RFQ document is key. This RFQ should clearly state every requirement in plain English to the greatest degree possible to clarify any confusion.

Creating an RFQ needs to have enough detailed specs to inform potential providers to get accurate responses.

Creating a Well-Constructed RFQ:

A robust RFQ document should include product specifications, quantities, delivery schedules and terms of payment among other key elements. Adding special requirements or conditions for bidders helps to make sure that suppliers have a full understanding of what will be expected of them.

To achieve both clarity and completeness, opt for plain language that enhances comprehension. Further, proofread the RFQ for completeness before sharing it, and solicit input from stakeholders to make sure all bases are covered.

"Now you don’t have to worry about drafting your RFQ! We’ve got you covered with our customizable RFQ template. Download it today and simplify your procurement process with ease!"

Step 2: Supplier Selection

Supplier selection is the most important step in the RFQ process. Outlining criteria for identifying qualified suppliers helps guarantee that the organization chooses vendors who are well-equipped to deliver on their needs. Evaluating potential vendors based on their capabilities and overall reputation sets the stage for a more fair and competitive approach to vendor selection that goes past pricing alone.

Open vs. Closed Bidding

Understanding the nuances between open and closed bidding processes can significantly benefit your organization in selecting the most suitable approach.

Allowing open bidding to all qualified bidders helps ensure more participation, competition, and transparency. A closed bidding process can shorten the timeline. It does this by artificially reducing competition to a small number of bidders.

A highly effective strategy is to create a “short-list” of pre-approved suppliers based on their past performance. Following this, implement a thorough vetting process to ensure each vendor meets the necessary qualifications. Keeping an updated centralized database of vetted vendors streamlines future RFQs, combining efficiency and effectiveness in procurement.

Step 3: Distribution

Good distribution channels are key to being able to reach the widest possible pool of potential suppliers. Using digital platforms, like digital procurement software, makes it easier to distribute the RFQ, ensuring that it gets in front of all the relevant suppliers.

Setting clear instructions and deadlines in the RFQ is pivotal, as it communicates expectations regarding bid format and submission timelines. Providing an avenue for suppliers to ask questions encourages open discussion and addresses any ambiguities quickly.

Step 4: Bid Collection

Getting a handle on a systematic approach for collecting all the incoming bids is crucial. This allows for all bids to be submitted through a secure and confidential process, while keeping an organized timestamped log of all bids received.

When you compare a manual collection system versus an automated system, the time, cost, and lack of errors created by automation speak for themselves. Implementing measures to protect sensitive information and establishing protocols for handling bid documents securely ensures confidentiality in the bidding process.

Step 5: Evaluation/Negotiation

A transparent and detailed evaluation process is essential for selecting the optimal bid. Implementing a proposal scoring system enables objective comparison of supplier proposals based on measurable criteria, rather than subjective opinions. Forming a diverse evaluation committee enriches the process by incorporating varied perspectives and experiences, helping to mitigate bias.

After reviewing bids, the key stage is negotiation. Engage with selected suppliers to clarify terms and address ambiguities, remaining open to adjusting quotes, prices, or delivery timelines as needed. Good faith negotiation seeks the best deal while fostering mutually beneficial relationships, essential for long-lasting partnerships.

A well-designed bid evaluation template is crucial for an objective and transparent evaluation process. It should encompass all important factors, including quality, delivery schedule, and service, not just price. Balancing these considerations is vital, as cost should not overshadow other elements that impact value and long-term success. By integrating evaluation with negotiation, organizations can secure stronger, more aligned deals that align with their strategic priorities.

“It’s important to look beyond purchase price to the total cost of ownership and focus on value.”

Step 6: Award and Notification

The sixth and final step is awarding the contract to the selected supplier and ensuring the decision process is thoroughly documented. Being ready for post-award discussions is key to working out the details of the contract and building a productive, collaborative relationship with the winning supplier.

Being prompt and professional in the way you notify other participants is important. Providing alternative advice and keeping communication cordial are important parts of good communication after an award, too.

Best Practices for an Effective RFQ Process

The RFQ process is essential for identifying the right suppliers, providing organizations with leverage to secure optimal, tailored terms. Here are best practices to enhance your RFQ process, ensuring thoroughness, transparency, and efficiency at every stage.

Documentation throughout the process

Having a standard method of documentation is a key element to having an effective RFQ process. Keeping detailed documentation of every interaction helps avoid misunderstandings and creates an easily accessible transcript of past conversations.

Keeping an exhaustive record of correspondence, meeting minutes, and phone calls helps ensure you are always up to speed on the status of work. It prepares you to address any problems that arise.

In addition, it’s important to document each determination that is reached during the evaluation phase. This helps to justify supplier selection, but more importantly it helps to maintain adherence to procurement policies.

To comply with internal and external policies and avoid potential legal issues, follow these best practices. Providing RFQ templates creates a level playing field by clearly outlining the project purpose and the required services or products, ensuring all bidders compete fairly.

Maintaining transparency and fairness

Maintaining transparency and fairness throughout the RFQ process is essential for building trust with suppliers. By clearly communicating the evaluation criteria and processes to all bidders from the outset, you foster an open environment where stakeholders understand how their proposals will be assessed. This practice minimizes confusion and promotes equity.

It is also crucial to avoid conflicts of interest and remain neutral during evaluations. Establishing a clear process for reviewing bids can help prevent favoritism and demonstrate fairness. Regularly reviewing and refining these processes will identify opportunities for improvement, ensuring they remain effective.

Another way to enhance transparency is by implementing a Q&A period within the RFQ timeline. Allowing vendors to submit questions and request clarifications on the project scope reduces the chances of miscommunication and ensures that all parties are aware of the requirements.

Leveraging technology for efficiency

Leveraging technology throughout the RFQ process can be a game-changer in making this workflow incredibly efficient to save everyone time. Procurement software automates much of the RFQ process, cutting down on manual labor and saving time while reducing mistakes.

For instance, RFX management systems just about instantly streamline the issuing of documents, freeing up teams to focus on high-value, strategic work. Technology is equally important in monitoring bids and maintaining supplier relationships.

Tools built for these functions provide unprecedented, real-time transparency and help with more productive communication. Once you implement data analytics, you take the process a step further by giving yourself the information you need to inform your decision-making and strategy.

Analytics can help identify trends and performance metrics, enabling agencies to make better-informed decisions when choosing a supplier. Three-quarters of proposal teams that embrace technology 100% of the time never miss a deadline on their proposals.

This statistic is a great example of how technology increases efficiency.

Potential Pitfalls and How to Avoid Them

The RFQ (Request for Quotation) process is essential but can be challenging, with potential pitfalls that may hinder your goals. Recognizing these pitfalls and learning to avoid them can significantly enhance your RFQ success. Regularly reviewing and refining your practices is crucial to staying ahead of the competition.

Common mistakes in RFQ processes

Lack of Clarity: Poorly defined requirements can confuse bidders, leading to proposals that do not meet expectations. For example, vague terms like “quick delivery” can be interpreted in various ways. Provide detailed specifications and clear expectations to avoid this issue.

Insufficient Outreach: Failing to widely distribute the RFQ or using overly restrictive selection criteria can result in missing qualified suppliers. Use a broad outreach strategy to attract diverse suppliers, leveraging both established connections and untapped networks.

Collaboration: Collaborate with colleagues across procurement to identify more potential suppliers, recognizing that teamwork can enhance supplier discovery.

Avoiding Bias: Establish clear evaluation criteria and guidelines to prevent subjective decision-making, leading to disputes. Set objective measures of success in advance and ensure all stakeholders agree on them.

Fairness and Transparency: Providing the same information to all suppliers is crucial for maintaining fairness and transparency throughout the process.

Strategies to prevent irregularities or abuse

Building in checks and balances would allow enough oversight to ensure the RFQ process isn’t pure window dressing. When there are regular audits and reviews of the process, any irregularities can be caught early on. Providing procurement teams with ethics training and compliance guidance sets baseline expectations for how standards should be upheld.

This alignment helps get everyone on the same page. A good whistleblower policy can be one of the most potent tools available for rooting out misconduct. It increases transparency and accountability, enabling problems to be corrected quickly without retribution.

Ensuring compliance with procurement policies

Understanding internal procurement rules is essential for aligning your RFQ processes with legal and organizational expectations. Regular independent audits help ensure compliance and safeguard against future issues.

Skipping the RFI (Request for Information) process may seem like a time-saver, but it often results in more time spent correcting errors later. An RFI clarifies needs and refines requirements, leading to a more streamlined RFQ process.

Timing is also strategic; submitting RFQs in the first quarter can provide a competitive advantage.

Tips for Creating Effective RFQs

1. Writing Clear and Concise Requirements

It all begins with providing clarity. When drafting RFQs, using simple language to articulate project needs and expectations is crucial. In short, clear communication avoids any fuzzy expectations, allowing potential bidders to know precisely what you need.

For instance, instead of getting too technical, aim for clear, accessible language that gets to the core requirements. By calling out key specifications that are priorities, you can clearly signal to suppliers what you need so they can tailor their proposals accordingly. This method is key to eliciting responsive bids that closely align with project objectives.

2. Structuring the RFQ for Easy Comparison

Clear Structure: Organize the RFQ into clear and logical sections to facilitate quick evaluation of proposals.

Use of Visuals: Incorporate tables or bullet points to enhance readability, especially when comparing three to eight vendor proposals.

Comparison Criteria: Ensure that all applicable criteria are clearly defined and easily comparable to identify the best supplier.

Q&A Period: Include a Q&A period of six to ten weeks to encourage transparency and avoid misunderstandings.

3. Incorporating Sustainability and Innovation Criteria

In a rapidly changing marketplace, including sustainability and innovation criteria in your RFQs can attract forward-thinking suppliers. Encouraging sustainable proposals integrates sustainability into procurement and enhances social impact.

Setting expectations for innovation prompts suppliers to offer creative solutions that add value. Evaluating bids based on environmental and social impact ensures broader community benefits. Furthermore, distinguishing between one-time deliveries and ongoing services influences how these criteria are prioritized and impacts future service planning.

Streamlining Bid Evaluation

Using Standardized Templates

Standardized templates are the foundation of a fair and systematic evaluation process. They create a common framework for competitive evaluators to use and trust. By capturing important criteria in a standard way, these templates help to ensure that each supplier proposal is evaluated on the same set of criteria.

Ultimately, this approach makes the evaluators’ job easier. It fosters trust with suppliers that their bids are being evaluated equitably. Ensuring scoring is consistent against all received bids is important, as it removes any favoritism from the process and increases transparency.

When evaluating a construction project, adapt the templates to focus on safety performance. Additionally, look back at the delivery timelines of past projects. Continuously adapting templates to address the unique needs of each project is how organizations stay nimble. It helps them to keep a high level of accuracy in their evaluations.

Implementing Scoring Systems

A solid scoring system is essential to making supplier evaluations a numbers game. By creating a scoring rubric that weighs different criteria, organizations can make it easier to compare options objectively. You can give varying weights to criteria such as financial health, adherence to specs, and previous successes.

This enables you to make trade-offs and prioritize what matters most to your project. Numerical scores make the whole comparison process more straightforward, allowing for quick ranking of suppliers. Training evaluators to apply the scoring system effectively and consistently is just as important.

This makes evaluations more consistent and accurate, resulting in better decisions overall. A requirement for a scoring system could help improve suppliers who always meet delivery dates. This more streamlined approach is much more in line with the organization’s mission.

Leveraging Data Analytics for Decision-Making

Adding data analytics to the bid evaluation process instantly improves the efficiency and effectiveness of decision-making. Learning from the past, analyzing historical bid data can provide useful information to inform current procurement strategies.

This means understanding trends in pricing, supplier performance, and project outcomes. Analytics tools help pinpoint those patterns, such as a supplier’s consistent ability to deliver quality products on time. This knowledge informs later procurement choices.

Focusing on data-driven decisions leads to better procurement outcomes, and it’s the right thing to do when you consider best practices. Begin collecting two to three years of financial data in advance of writing an RFQ.

This step gives you the groundwork to ensure you’re able to budget accurately and evaluate suppliers comprehensively. This approach combined with analytics analysis helps organizations to be strategic, data-driven, and more effective in their decision-making.

Conclusion

The RFQ process has a unique place in procurement. Instead, it lays the groundwork for strong supplier relationships and deeper cost savings. Complete these six steps in conjunction with these best practices detailed in this guide. You will develop RFQs that yield competitive responses and create unambiguous expectations. Navigating these common pitfalls and knowing the key differences between commercial and government procurement will help make your strategy more robust. Armed with these insights, you maximize bid evaluations and expedite decision-making.

Get started on your procurement efficiency by utilizing our RFQ feature. ProQsmart ensures your workflow is more intuitive and your program more effective. Book a demo today!