Request for quotation, or RFQ, quickly allows teams to receive firm prices and lead times from vendors. More than anyone else in custom manufacturing, manufacturers depend on RFQs to set internal budgets, weigh different suppliers, and meet project deadlines.

RFQs provide structure to the purchasing process and provide teams with objective information to make informed decisions. The next sections show how to write good RFQs, pick the right details, and speed up supplier feedback for smoother projects.

What is a Request for Quotation?

A request for quotation, or RFQ, is a formal, intensive process. In this second step, a firm requests that shortlisted vendors or subcontractors submit their price proposals for an outlined project scope or set of goods.

This is truer when it comes to large orders of components or products. Businesses provide them a detailed document with precisely what they’re looking for—what they need, how much they need it, when they need it by. Suppliers then respond with their lowest price available. The goal is simple: get the right goods or services at a fair price.

RFQs move in the opposite direction from open-ended requests. They work best when specs are set in stone, and there is almost no room for interpretation. Companies see value, too—over 80% report that the RFQ satisfies their needs.

A standard RFQ has four main chunks: prep, process, award, and close. During this stage of preparation, teams collect procurement needs and specifications. Processing involves circulating the request and receiving proposals. Awarding is choosing the lowest bid that checks off all of the must-haves.

For closing, we mean shaking hands and starting the work. RFQs serve as a gateway to smaller jobs, sometimes even used to foreshadow larger, more complicated RFPs.

RFQ vs. RFI vs. RFP Differences

RFQs, RFIs, and RFPs each fill a specific need. RFQs are all about price for defined specifications. RFIs for information requests are used in cases where the buyer hasn’t received the level of understanding they require.

RFPs solicit concepts and solutions when the work is complex. Issue RFQs when specifications are already determined, RFIs when the goal is to gather information and learn, and RFPs when handling large, complex, open-ended projects. Compared to RFPs, RFQs are simpler—no huge hoops to jump through, no long waiting periods for responses.

When to Use an RFQ Effectively

RFQs are greatest when the specifications are clear and price is the most important factor. For instance purchasing 1,000 steel fasteners, purchasing office chairs or contracting with a cleaning crew.

These jobs are very straightforward – so vendors can straightforwardly provide a price. RFQs are competitive, quick, and largely non-political, favoring the firm that can provide the most value.

Core Purpose of RFQs in Sourcing

RFQs, or Requests for Quotation, are an essential tool in sourcing and procurement. They ensure that buyers receive comparable pricing and technical data from all potential suppliers. This critical step allows buyers to compare bids on a level playing field and select the solution that best fits their needs.

Only about 35% of enterprise procurement teams leverage AI to automatically handle RFQs. This pivot underscores the increasing role that these tools are playing in helping municipalities make smarter data-driven decisions and save workflow time.

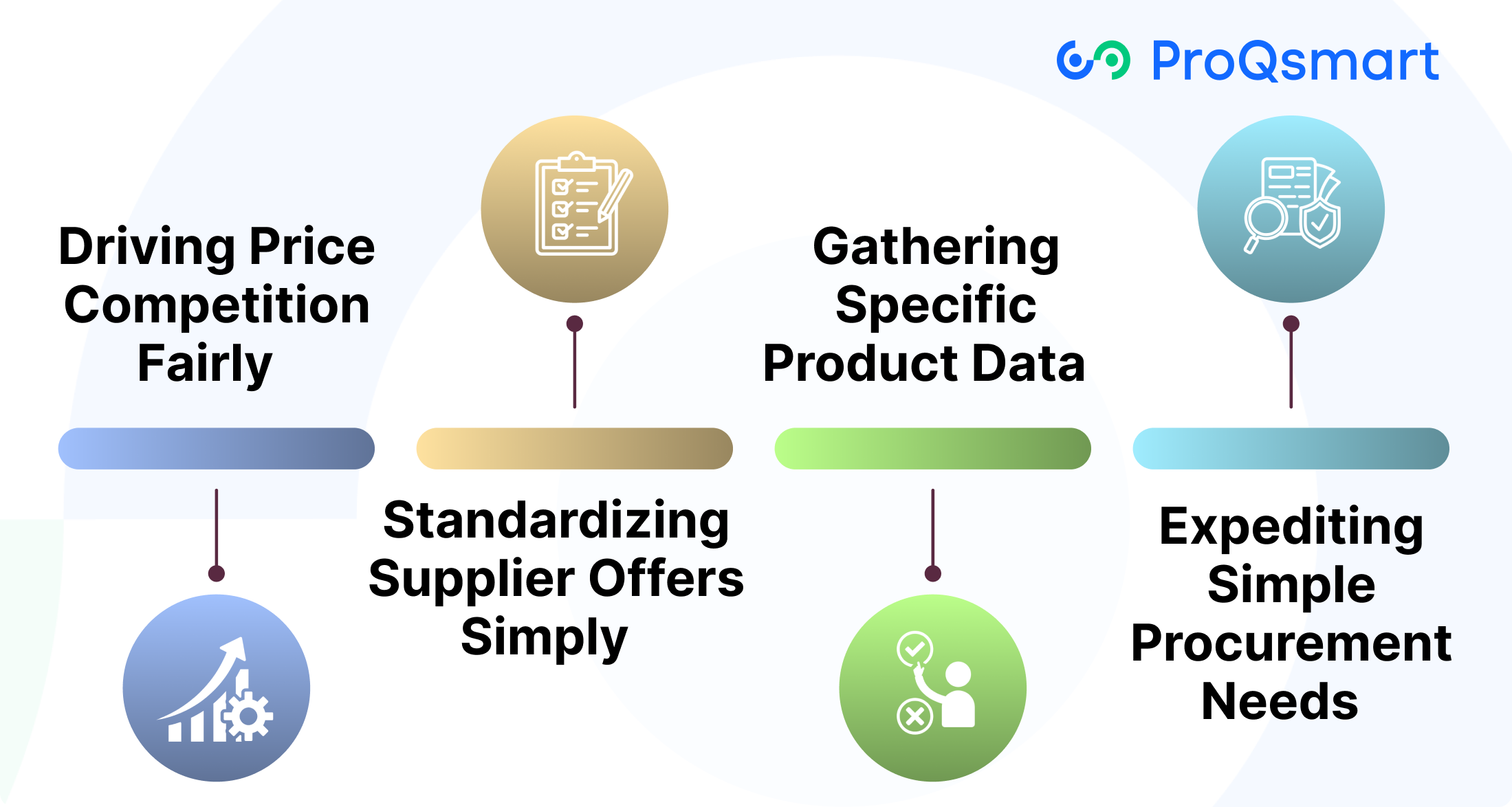

Driving Price Competition Fairly

RFQs help drive open, competitive bidding environments, allowing suppliers to submit their most competitive prices in a level playing field. Each supplier receives the exact same specs and information up front.

Buyers regularly and actively use this system to solicit bids. This enables them to identify savings opportunities leading to millions saved per contract awarded. Platforms such as ProQsmart further improve this transparency.

Beyond that, they give buyers a live look into bidding, allowing for all vendors to see equal information provided to everyone as well as keeping the whole process transparent and honest.

Standardizing Supplier Offers Simply

RFQs establish a defined template for response, ensuring that all suppliers submit their information in the same structure. This greatly simplifies the task of procurement teams to review and score the proposals.

Having a standard, easy-to-read format, teams can identify the top choice quickly. Standardized RFQ documents reduce confusion as well, allowing specification items such as price and product attributes to be readily listed and compared.

Gathering Specific Product Data

By avoiding excessive detail in RFQs (Request for quotation), buyers can receive the right information on the first submission. This might extend to desired product features, quality requirements, and even aspects of required delivery.

By clearly articulating this from the start, buyers receive great data that informs their ultimate decision. Procurement teams can use this information to better plan upcoming purchases or identify emerging trends.

Expediting Simple Procurement Needs

RFQs are great for purchasing commoditized items, allowing for quick turnaround for bids received and selection of a playing partner. This minimizes time and effort for routine, repeat buys allowing things to flow.

By letting automated platforms handle minute details, the process becomes a breeze and teams can spend time on larger initiatives.

Crafting an Effective RFQ Document

An effective RFQ (Request for quotation) provides complete and specific information to encourage meaningful discussions with suppliers. Teams who spend the additional time polishing an RFQ are handsomely rewarded. That work makes the process less confusing and avoids missteps that can lead to major headaches later. Having clear connections between RFQs and project goals ensures everyone’s head stays in the game. This is the case regardless of whether the team is working on a tiny custom piece or a huge commercial fabrication. In fact, nearly 80% of construction projects go based on RFQs, demonstrating the enormous confidence the industry has in this method

1. Define Clear Scope and Requirements

Considering requirements in their totality, it can be useful to begin by stating precisely what is required. Teams often include detailed technical specs. They specify, for instance, what algorithms need to be run, how the software should interface, and what data security protocols are required.

With detailed and specific requirements outlined in writing, vendors provide more accurate and competitive proposals. For instance, including a BOQ—similar to a shopping list of materials—takes out a lot of guesswork.

2. Specify Quantities and Delivery Needs

Second, quantities must be clear and precise, as opposed to just hopes. Specific delivery requirements like “delivery of 200 units in 60 days” help move this along. Timelines became an important factor.

Many small RFQs do best with a two-week period, but larger, more complex projects may need an RFQ (Request for quotation) period of six to ten weeks.

3. Outline Submission Instructions Precisely

RFQs should detail how to submit proposals, including the solicitation format and pricing table, what format to submit in, and where to direct inquiries. When you have transparent guidelines, prospective vendors understand the bidding process and timeline upfront.

4. Detail Pricing Structure Expectations

Using a price template, like those in ProQsmart, helps everyone compare apples to apples. Some section on what to include in their costs—materials, shipping, fees—so there’s no confusion.

In other words, unless all requirements are fulfilled, lowest price takes it on 80% of RFQs.

5. Include Terms and Conditions Clearly

Payment and delivery particulars must be clearly stated from the start to ensure a successful RFQ. Teams will include penalties for not meeting deadlines and will define the rules of engagement for the procurement cycle, keeping it fair for both parties.

6. Set Realistic Response Deadlines

Providing vendors adequate time is important. Vendors deserve adequate time to respond to an RFQ. Many teams juggle short deadlines with how busy our suppliers are.

In haste, bids are more likely to contain errors or lost opportunities.

7. Define Evaluation Criteria Upfront

Teams outline their scoring criteria for the bid process, explaining how they’ll score each vendor RFQ reply. Providing these metrics upfront allows potential vendors to better tailor their quotes to meet them.

8. Incorporate Compliance Requirements

RFQs should identify any legal or safety regulations required, which aids in filtering out potential vendors who can’t meet the bar and smooths the bidding process down the line.

Essential RFQ Template Elements

A well-prepared RFQ (Request for quotation) template facilitates the work of the procurement process. It allows for speed of teams, which minimizes risk of mistakes occurring. When they adopt a standard format, buyers and vendors alike have more familiarity with the process.

It creates the right environment for good, clear agreements and less back-and-forth. Templates further ensure that teams deliver on schedule and align with state and federal compliance requirements. Since nearly 90% of public procurement teams use RFQs to procure goods and services, a good RFQ template is essential.

Key Information Fields Checklist

A thorough RFQ template never forgets to include the buyer’s and vendor’s contact information. It needs to display all submission deadlines and explicitly outline requirements for vendors to bid.

Clear project scope and description of why the RFQ (Request for quotation) is needed allows vendors to understand what’s at stake. Provide an itemized list of the products or services requested, including estimated quantities and any specific requirements.

Including a Bill of Quantities (BOQ) allows vendors to accurately price their rollout and plan accordingly. Delivery requirements, evaluation criteria, and general terms and conditions, including payment terms, warranties, and contract duration, ensure transparency.

Clearly labelled schematic drawings or conceptual designs provide additional detail. Yielding optimal results, they short-list three to eight vendors, wanting up to eight responses.

Designing User-Friendly RFQ Layouts

A straightforward structure with invitingly named sections helps maintain focus. Using tables or other visuals helps convey specs and requirements quickly.

Whatever you include, it’s a good idea to make it as easy to scan as possible. When layouts are tidy, vendors are able to submit bids with fewer clarifying questions, resulting in more competitive bids in a shorter timeframe.

Downloadable RFQ Template Considerations

Downloadable templates save time and allow teams to creatively modify fields to reflect the work that they do. It’s no longer enough for them to simply work alongside other, newer procurement tools like ProQsmart, which automates workflow, tracks spending, and centralizes supplier data.

This approach ensures that all teams are always aligned and decisions are made clear and straightforwardly.

Evaluating RFQ Responses Strategically

A solid way to look at RFQ (Request for quotation) responses helps teams make smart picks, hit cost targets, and avoid missed details. They review qualifications chronologically to identify real quality. This process allows them to identify gaps and prioritize in accordance with their overarching priorities.

Industry pros know that without a clear plan, only one percent of RFPs are successful. So, while conducting a thoughtful and strategic review is a good idea, it’s necessary.

Comparing Apples-to-Apples Bids

Teams achieve significantly stronger outcomes when they rely on equitable, transparent criteria for evaluating each proposal. Good criteria include: price breakdowns (labor, materials, monthly fees), tech specs, lead time, warranty, and service terms.

They require quotes in a specific format, so all responders list prices and information in a uniform manner. This helps you easily identify variations in their responses or any hidden costs.

With a template, such as what ProQsmart provides, no important line item slips through the cracks. When all are held to the same high bar, the decisions become clearer and are made faster.

Assessing Supplier Capability Beyond Price

Selecting a partner involves more than just selecting the lowest price. To start, teams can evaluate how reliable and capable the supplier is. They look for past work and ask for references.

They will additionally check to see that your service level agreements (like 99.9% uptime or four-hour ticket resolution) were met. Considering these far-reaching connections avoids pitfalls down the road, fostering goodwill and transparency.

Using Weighted Scoring Methods

A weighted score allows buyers to place emphasis on what is important to them. For instance, they might decide to weight price at only 40%.

Perhaps they want to weight 30% for skill, 20% for service fit, and 10% for money health. This ensures that a high quality proposal in one section cannot compensate for deficiencies in others.

Verifying Supplier Information Thoroughly

Due diligence prevents bad surprises from occurring. Teams make reference, record, and performance inquiry due-diligence RFQ calls to confirm people, teams, and projects.

This step reduces risk and identifies partners committed to follow-through.

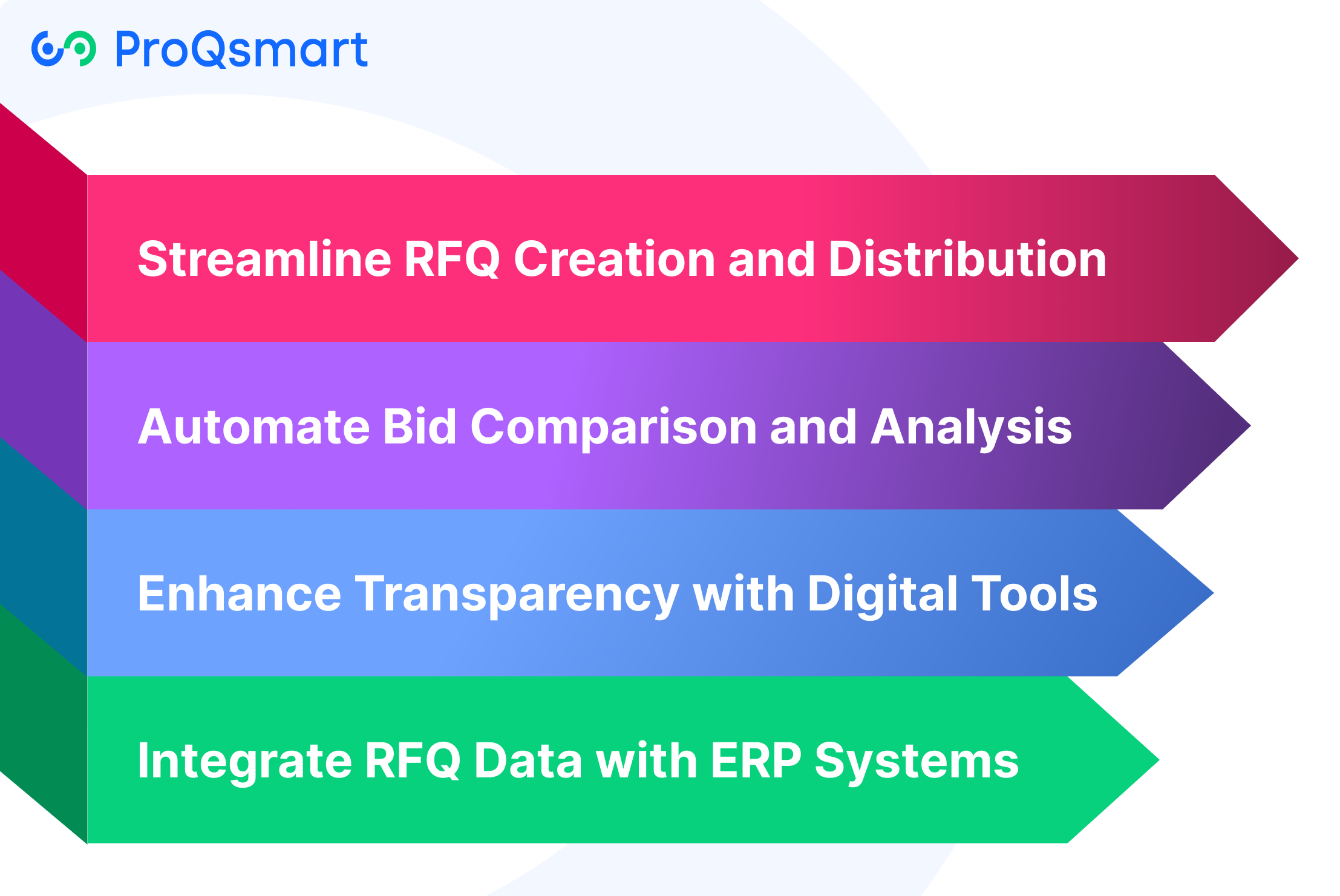

Leverage Technology for RFQ Automation

Today’s on-demand custom manufacturing teams realize substantial results by adopting automated RFQ technologies. Integrating digital platforms accelerates each stage, from creating an RFQ to selecting a final bid. With automation, you’ll spend less time on paperwork and more time on what really matters.

It enables small shops and large plants to both stay competitive or even get ahead as the market demands shift at breakneck speeds. Digital RFQ software lets teams handle growing order volumes, manage supplier lists, and track bids without the slowdowns of email or spreadsheets.

Streamline RFQ Creation and Distribution

Automating RFQ creation gives teams a clear workflow.

-

Fill in part specs and volume online.

-

Use templates for fast setup.

-

Route for quick team approvals.

-

Auto-send to chosen suppliers.

-

Track status in one dashboard.

The right RFQ platform enables teams to communicate and collaborate with potential suppliers within the same platform, creating an audit trail in one location. This arrangement eliminates the risk of human error, such as forgotten attachments or incorrect dates, ensuring consistent communication and understanding across teams.

Suppliers can upload their bids directly into the system, and the software can send notifications of new changes.

Automate Bid Comparison and Analysis

With RFQ automation, teams receive quick, side-by-side comparisons of bid submissions. These tools automatically pull in pricing, standard lead times, and quality data for each bid.

Automated sorting and ranking of available options makes it easy to find the best value possible without having to comb through numerous emails. Automation in this space cuts hours out of the RFQ review process, allowing engineers and purchasing agents to make intelligent, quick decisions.

Enhance Transparency with Digital Tools

Digital RFQ platforms ensure a level playing field. Everyone is operating on the same spec and timeline, so nothing gets lost in translation. Audit logs automatically record every change made and message sent, creating an easy-to-follow trail that builds trust with vendors.

The ability to share files and updates in real time means never having to wonder who received what information or when.

Integrate RFQ Data with ERP Systems

Integrating RFQ tools with ERP systems can arm internal teams with a complete view of the supply chain. Through one cohesive view, orders, contracts, and supplier data all come together.

Beyond reducing double entry, this link provides insights on trends in spend or lead time across sites. Planning teams receive better data to inform their planning, and it assists operations managers find deficiencies in real time.

Overcome Common RFQ Challenges

The RFQ process is full of moving parts and obstacles. This is even more pronounced for teams involved in bespoke manufacturing or construction. Unfortunately, many are plagued by challenges such as unclear specs, underwhelming supplier response, and demanding timelines that can derail the entire process.

Unclear terms, omission of required steps, and basic clerical mistakes are the usual culprits behind these roadblocks. In reality, 40% of contractors fail on construction RFQ submissions because of simple, avoidable errors. With a strategic approach and the right technology, teams can improve their win rates by as much as 31%.

They can’t even deliver bids on time, unlike the 75% of proposal teams that rely on technology every day.

Mitigate Vague Specification Issues

Detailed specifications lay the groundwork for all that follows. When teams write out each specification—down to the materials, timeline, testing or compliance required—vendors have an understanding of what is necessary. Otherwise, suppliers will have to speculate or make assumptions, resulting in ill-fitted bids or costly overruns.

Frequent RFQ reviews by market-savvy engineering or procurement pros identify holes and ensure each requirement is unambiguous. Both teams realize that more specific specs = more precise bids. This method removes ambiguity and saves precious time that would’ve been wasted in further communication clarification.

Address Low Supplier Engagement

Without adequate supplier engagement, you’ll end up with a smaller pool of options and less competition. Teams increase their chances of getting good responses when they are responsive, answer questions quickly, and seek to make the RFQ process as easy as possible.

Providing constructive feedback for each unsuccessful bid allows suppliers to understand where they can improve and encourages them to reapply. ProQsmart’s e-tendering platform makes document management easier and faster than ever. It’s not only for them, it effectively updates suppliers and brings in more supplier responses.

Ensure Fairness and Transparency Always

Fairness ensures that trust remains in full supply during the bidding process. The best teams are able to level the playing field by treating all vendors equally and documenting every step of the vendor RFQ reply process. ProQsmart’s built-in reporting and audit trails provide complete transparency and foster the development of sustainable, long-lasting supplier relationships.

Manage Tight Timelines Effectively

Deadlines may be inconvenient, but they are a reality. Teams that stay organized, delegate effectively, and leverage tools that integrate and streamline processes such as ProQsmart make quick work of it without missing a beat.

By focusing on the highest priority must-do steps first and tracking progress in real-time, we stay on track.

Adapt RFQs for Industry Nuances

Is it hard to picture, and yet every sector is different. Teams that personalize RFQs—adding custom swimlanes, specifications, or compliance requirements—receive more targeted and competitive bids.

Because ProQsmart allows users to customize templates for each job, responses are tailored to what’s actually required.

Conclusion

RFQs take the guesswork out of sourcing and go straight to the point. Teams receive better quality bids, streamline processes, and reduce expenses. A well-crafted RFQ tells them exactly what they are looking for, establishes the rules of engagement, and elicits competitive pricing. Today, tech tools automatically organize quotes, identify potential red flags, and queue up alternative suppliers. The right RFQ avoids the noise, allowing teams to identify real value. Each action taken, from developing specs through the proposal review process, helps create better deals. Equipped with better data and better tools, teams go from making educated guesses to making smart, defensible picks. As seen in industries such as auto parts or metal fabrication, RFQs lead to improved supply chain efficiency and responsiveness. The RFQ teams that harness it effectively often lead the way in cost and time. Looking to improve your procurement process even further? Learn more about ProQsmart and schedule a demo today!