In manufacturing, unpredictable supplier risks—such as unexpected delivery delays, inconsistent product quality, or supplier financial instability—can significantly disrupt operations, leading to missed production deadlines, escalated costs, and dissatisfied customers. These challenges often arise from volatile market conditions, geopolitical disruptions, or supply chain bottlenecks, making it difficult for procurement teams to maintain stability and efficiency. Traditional procurement methods, reliant on manual processes and limited visibility, struggle to address these dynamic risks effectively. Supplier Relationship Management (SRM), enhanced by AI-driven insights within e-sourcing platforms, transforms this landscape by offering real-time risk monitoring, predictive analytics to anticipate disruptions, and streamlined supplier collaboration to ensure alignment with operational goals. This article explores how SRM with AI empowers procurement professionals to proactively manage supplier risks, providing practical strategies and tools to safeguard manufacturing operations, optimize supply chain resilience, and drive cost-efficient outcomes.

Unpredictable Supplier Risks in Modern Procurement

Manufacturing procurement’s unpredictable supplier risks include sudden supply chain interruptions and potential supplier bankruptcies, which can derail operations unexpectedly. Manufacturers now face challenges not only with their direct suppliers but also with fourth-party relationships and external shocks like pandemics or geopolitical shifts. Each scenario presents its own dangers, such as credit, liquidity, operational, or market risks, including delivery delays, non-compliance, and inconsistent quality. Implementing effective supply chain risk management, continuous supplier evaluation, and clear contingency planning are essential to safeguarding organizational priorities.

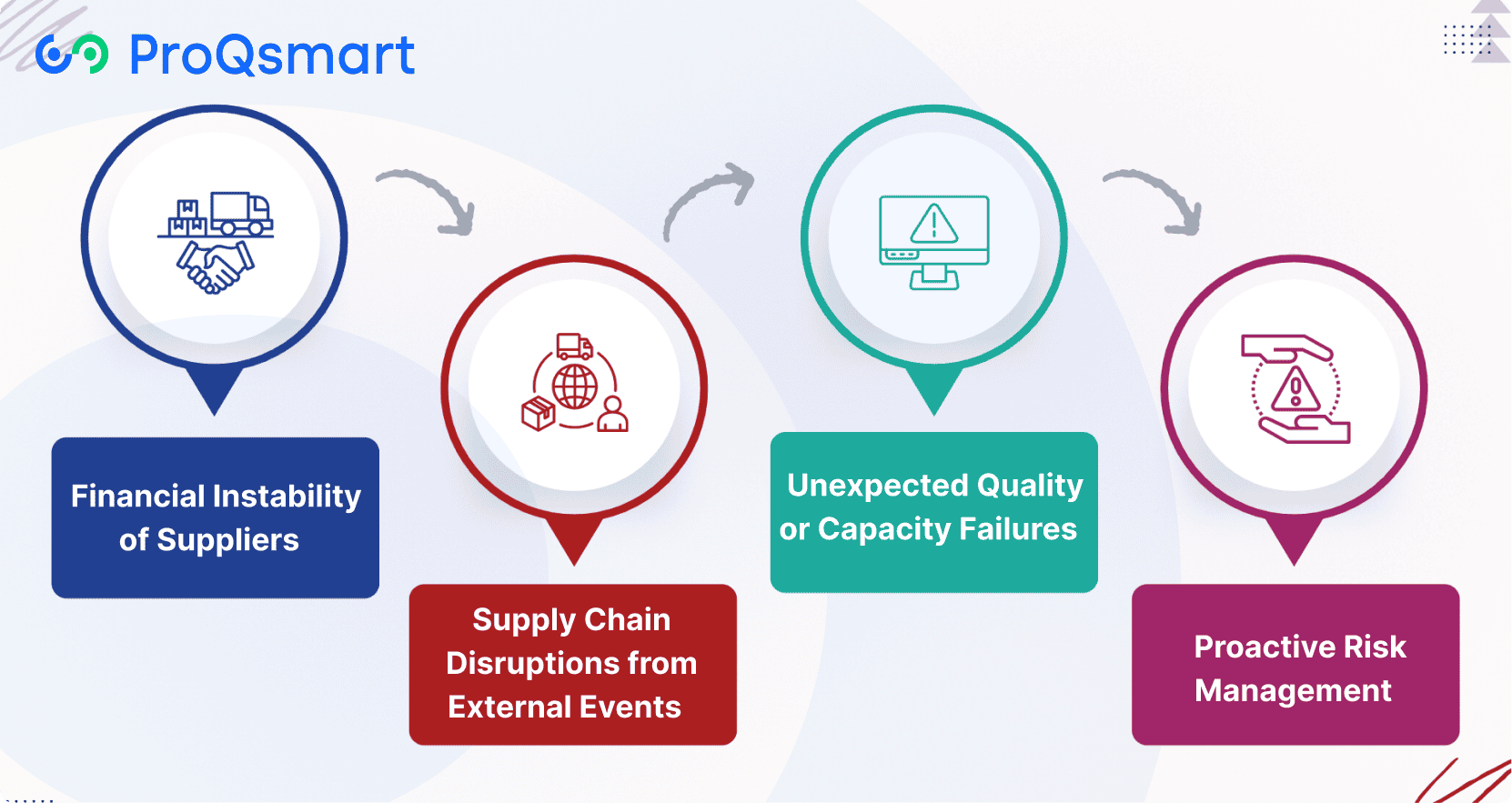

Financial Instability of Suppliers

Late payments, sudden price increases or unanticipated executive changes can all be early indicators of a supplier’s financial distress. These troubles tend to be an indicator of more serious underlying problems, such as cash flow issues or increasing debts, which may not yet be apparent.

To evaluate supplier financial health, organizations need to monitor key indicators such as credit ratings, payment history, and income trajectory. Frequent tracking of these data points, coupled with ongoing conversations about financial health, simplifies the early identification of emerging risks. Transparent conversations with suppliers regarding their financial situation fosters fewer surprises and enables collaborative contingency planning should issues emerge. Conducting regular risk sensing reports allows sourcing professionals to change sourcing strategies or line up alternative suppliers before uncertainty becomes a supply chain rupture.

Supply Chain Disruptions from External Events

Natural disasters, political unrest, and pandemics are the top external events causingsupply chain disruptions, according to Kinaxis. Material shortages, sudden export bans or logistical shutdowns can hit fast and surprisingly hard.

It’s important to develop strong contingency plans for every kind of disruption. This ought to involve predefined plans for changing suppliers, rerouting shipments, and modifying production schedules. Diversifying the supplier base, both geographically and across different product categories, minimizes dependence on any one source. Solutions such as real-time tracking and supply chain visibility tools enable companies to identify problems in advance and respond proactively.

Unexpected Quality or Capacity Failures

In modern manufacturing, unpredictable supplier risks are the new quality problem. Real-time analytics allow you to monitor manufacturing capacity and prevent unexpected stockouts or excess inventory.

Transparency helps teams address quality or capacity issues as they arise, diminishing the danger of long-term disruption. Backup supplier contingencies have to be current, so a swap can occur rapidly if necessary.

Proactive Risk Management

-

Regular risk monitoring is vital.

-

Supplier mapping helps highlight hidden risks.

-

Smart planning protects against unpredictable events.

-

Continuous updates keep strategies relevant.

How Supplier Risks Impact on Procurement Operations

Supplier risks in manufacturing procurement can unleash significant supply chain disruptions that topple business operations, inflate costs, and damage brand reputation. If firms rely on a single supplier and don’t monitor their performance, they leave the door ajar for procurement risks such as late deliveries, defects, and cyberattacks, impacting inventory management and customer trust.

Project Delays and Cost Overruns

Supplier disruptions–late deliveries, abrupt quality issues–are among the top reasons projects get delayed. Logistical problems — such as a transportation breakdown or customs slowdown — can stop production lines from operating. Unexpected price increases, extended timelines and inefficient resource utilization all increase costs. Take a financially-troubled supplier, for instance, which might charge more or skimp on quality simply to survive. If a manufacturer needs to change suppliers quickly, additional expenses for rush orders or air-shipping become nearly inevitable. Panic overstocking, or late shipments causing stockouts, immediately impact cash flow and customer satisfaction.

They can minimize these effects by maintaining open lines with vendors, conducting periodic performance audits, and having contingency plans. Mapping out fourth-party supplier connections and applying transparent IT security policies assist in preventing or mitigating risks. Ongoing risk observation implies that warning signs are captured early, before they escalate.

Compromised Quality and Client Trust

Diminished quality is a risk that can rapidly destroy client confidence. When suppliers come up short – products may get returned or require rework, both costly and time-consuming. If quality control is lax, even a reliable long-standing supplier can turn into a hazard.

Quality control measures, like regular audits and sample tests, assist in keeping supplier performance in check. It’s crucial to be mindful not only of the final product itself, but of the process and materials used. Firms should track KPIs such as defect rates, on-time delivery and complaint response.

Open communication with suppliers facilitates rapid problem resolution. This maintains the relationship and quality remain high. That means firms shouldn’t be afraid to discuss ESG risks, as these can impact brand image and customer trust.

How SRM Mitigates Supplier Risks

Supplier risk management (SRM) has transformed the way manufacturing procurement teams respond to unpredictable supplier risks. By utilizing a strategic procurement approach with automated tools and AI, SRM identifies, monitors, and mitigates potential risks. This proactive supplier risk management enables teams to formulate risk plans, implement best practices, and leverage real-time data to keep supplier performance on course. Working with the right SRM system allows procurement teams to stay ahead of threats like delivery delays and quality drops.

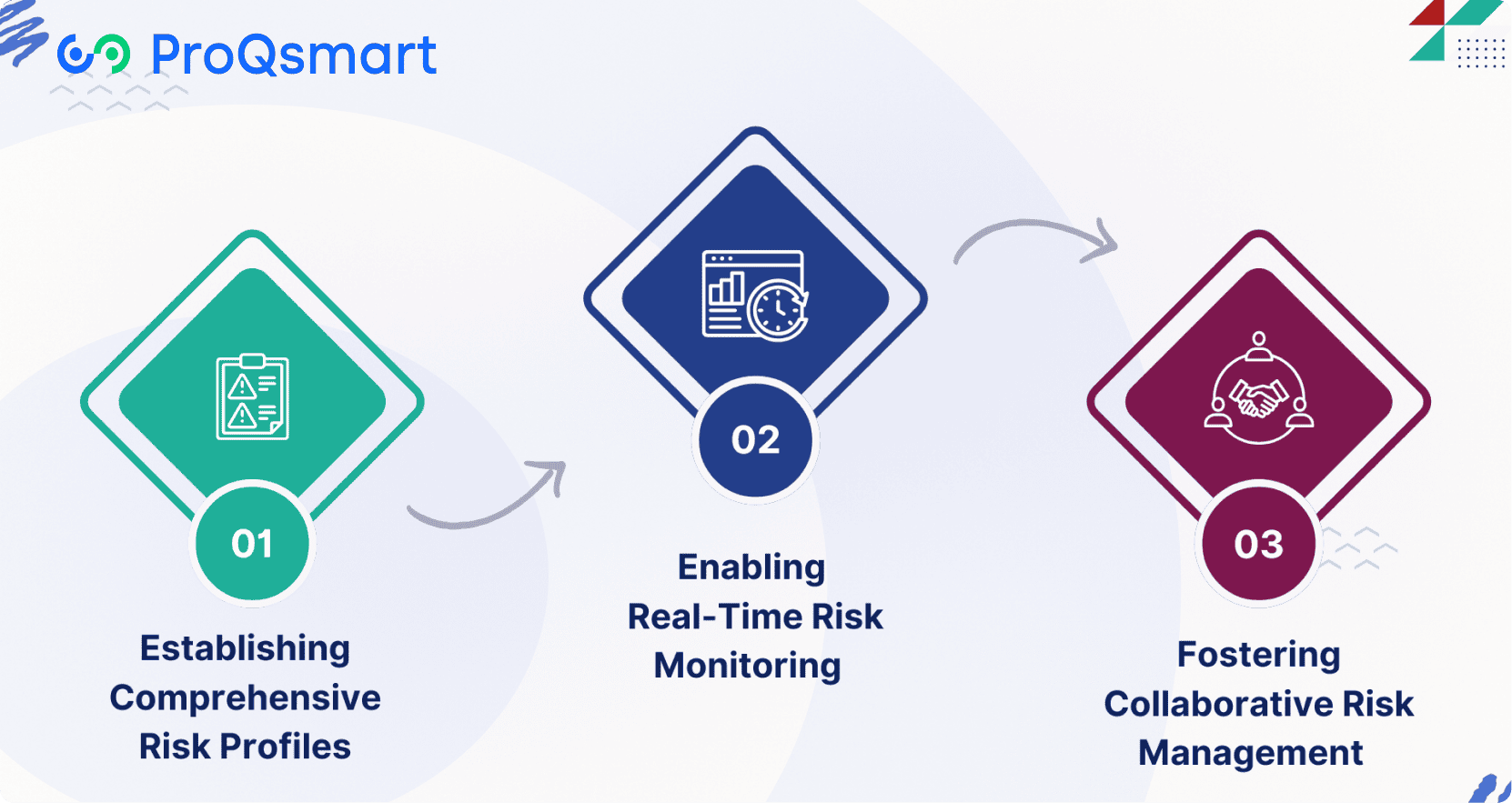

Establishing Comprehensive Risk Profiles

An effective SRM program begins with a risk profile for each of your suppliers. Key factors include supplier financial stability, delivery history, product quality and external risks such as political changes or regulation. Some teams consider sustainability and ESG elements, such as audits and green certifications. AI simplifies this task by scanning supplier information, market news, and audit reports.

They start by collecting supplier data from audits, financial reports and third-party sources. Then, they leverage AI to evaluate trends and identify patterns. Teams then configure risk scores and discuss these with other divisions. Continuous checks and updates are important, because supplier risks evolve. Easy checklists ensure procurement teams stay on track and don’t miss any updates.

Enabling Real-Time Risk Monitoring

SRM systems now provide real-time capabilities such as predictive analytics, instant alerts, and live dashboards. These capabilities allow teams to monitor critical suppliers, configure alerts, and respond promptly to any concern. Teams select their most strategic suppliers, establish transparent objectives, and leverage dashboards to detect shifts in real time.

Real-time monitoring is about aggregating all supplier data in one system and setting alerts for late shipments or quality dips. That results in improved decisions and more rapid responses — with fewer overlooked risks. Teams identify deficiencies and resolve them before they become larger issues, assisting in minimizing downtime and maintaining stable supply chains.

Fostering Collaborative Risk Management

Collaboration is the heart of SRM. Teams and suppliers collaborate with mutual objectives, transparent discussions, and transparent metrics. Partner risk checks and action plans help identify and resolve issues earlier. For example, ProQsmart’s AI-powered platform helps teams and suppliers work together, share dashboards, and manage compliance and audits in real time.

Defined roles and routine meetings generate trust and keep all parties accountable. Everybody knows what to scan for and how to respond if something shifts. This collaboration reduces the risk of overlooked risks and accelerates solutions.

|

Method |

Risk Management |

Efficiency |

Supplier Engagement |

|

Traditional Procurement |

Reactive |

Low |

Transactional |

|

SRM with AI |

Proactive |

High |

Collaborative |

Enhancing SRM with E-Sourcing Technology

Modern Supplier Relationship Management (SRM) faces unpredictable supply chain risks in manufacturing procurement. E-sourcing technology can help organizations manage these risks by automating manual processes, centralizing supplier data, and enabling real-time performance monitoring. The integration of Artificial Intelligence (AI) and Machine Learning (ML) into e-sourcing platforms supports predictive analytics, effective procurement strategies, and better decision-making. These tools are becoming vital as companies seek more efficient and transparent supplier management.

Leveraging AI-Powered Predictive Analytics

AI-powered predictive analytics help organizations identify supplier risks in advance, optimize forecast accuracy, and back decisions with real-time data. Improved forecasting accuracy anticipates supply chain disruptions and early detection enables faster risk mitigation. These analytics enhance trust in supplier selection and performance monitoring.

To utilize AI-driven predictive analytics, identify key data sources like past supplier performance, quality records, and delivery times. Next, organizations select appropriate analytics tools capable of managing high data volumes. Staff training is crucial here, making sure users understand new systems and can read the insights they provide.

|

Approach |

Efficiency |

Accuracy |

Response Time |

|

Traditional risk assessment |

Low |

Medium |

Delayed |

|

AI-powered analytics |

High |

High |

Real-time |

Automating Risk Assessments and Alerts

To automate risk assessments, companies first define key risk factors—such as late shipments, quality issues, or compliance breaches. Then, they set up automated data gathering from supplier reports and third-party sources. Establishing alert thresholds ensures that the system triggers notifications when critical metrics deviate.

|

Method |

Speed |

Accuracy |

Scalability |

|

Manual risk assessment |

Slow |

Prone to error |

Limited |

|

Automated system |

Fast |

High |

Scalable |

Real-time alerts are essential to supplier performance management. With integrated monitoring, your team can quickly respond to issues as they arise — minimizing downtime and monetary impact. Predictive analytics additionally provide by predicting potential disruptions, allowing organizations to act before issues scale.

Centralizing Data for Unified Insights

Centralizing procurement data makes you smarter, supplier collaboration stronger, processes smoother. It makes supplier data, risk scores, contracts, and performance easy to view and compare.

Effective data centralization starts with legacy systems integration and data format standardization. Continuous training keeps your staff up to speed on how to use new platforms and tools. Hurdles linger–multiple organizations suffering from data silos, change aversion, and system updates.

Comparing Traditional and AI-Enhanced SRM

|

Feature |

Traditional SRM |

AI-Enhanced SRM |

|

Predictive analytics |

No |

Yes |

|

Real-time monitoring |

No |

Yes |

|

Automated assessments |

Limited |

Fully automated |

|

Cost savings |

Moderate |

High |

Building Resilient Supplier Networks with SRM

Supplier relationship management (SRM) is crucial for effective supply chain risk management, as it helps businesses identify and address risks originating from third-party connections. It transcends mere sourcing activity through continuous verification, intelligent sourcing planning, and true collaboration with reliable suppliers. This creates a network capable of absorbing shocks, adapting to changes, and maintaining supply flow when the going gets tough. SRM is unique because it examines every link in the chain, not solely the initial level. As international supply chains grow more complex, a robust SRM strategy is essential.

|

Features |

Traditional Procurement |

SRM-Enhanced Procurement |

|

Supplier focus |

One-time transactions |

Long-term partnerships |

|

Risk handling |

Reactive |

Proactive and continuous |

|

Data use |

Manual, scattered |

Real-time, centralized, AI-supported |

|

Performance |

Occasional checks |

Ongoing, with clear metrics |

|

Collaboration |

Limited |

Shared innovation and transparency |

Diversifying Supplier Bases

Diversify risk by incorporating additional, local and global suppliers through effective supplier risk management. Begin with a map of existing suppliers, then seek out holes or over-dependence on a single supplier. Identify new partners that fit your criteria and rate them on factors like quality, speed, and ability to scale. Opt for local suppliers for quick responses and global ones for extensive coverage to mitigate supply chain risks.

Maintain freshness in your procurement processes. Establish a habit of reviewing your list—insert new names, delete bad performers, and notice patterns. This keeps your network resilient and primed for significant supply chain disruptions.

Collaborate with multiple suppliers simultaneously. This reduces the risk of a single large issue disrupting your supply. It helps keep prices honest.

Build trust. Visit suppliers, exchange objectives and collaborate on new concepts. It makes both sides thrive and survive hard times.

Integrating Risk-Aware Performance Metrics

Watch supplier risks with key metrics: on-time delivery, steady quality, money health, and contract compliance. Tie these to your key objectives so you detect vulnerabilities early.

Utilize tools that measure metrics in real-time. ProQsmart, for instance, enables teams to identify issues immediately, helping to stay on track and compliantly on track.

Dive into historic data. Anticipate the next thing that could break. This assists in plotting repairs before trouble begins.

Present all this in a dashboard. Give managers the big picture—risk levels, trends, and gaps—at a glance.

Conclusion

Supplier risk remains a critical concern in the manufacturing sector, where delays or disruptions can quickly impact costs and operational performance. Implementing robust Supplier Relationship Management (SRM) practices enables procurement teams to proactively identify potential vulnerabilities, access transparent supplier data, and address issues before they escalate. E-sourcing platforms further enhance risk management by providing comprehensive data and streamlining due diligence processes. Building strong, collaborative supplier relationships not only secures better terms but also increases confidence and resilience within the supply network. Organizations that prioritize SRM and leverage advanced e-sourcing tools are better positioned to navigate market fluctuations, minimize disruptions, and achieve sustainable growth. To explore how ProQsmart can support your supplier management strategy, consider scheduling a demo.